Thin fire-resistant/flame-retardant paint for tunnel and preparation method thereof

A technology for fire-retardant and flame-retardant coatings and tunnels, applied in the field of flame-retardant coatings, can solve the problems of not being able to meet the fire safety requirements of tunnels, endangering driving safety, easy to fall off, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

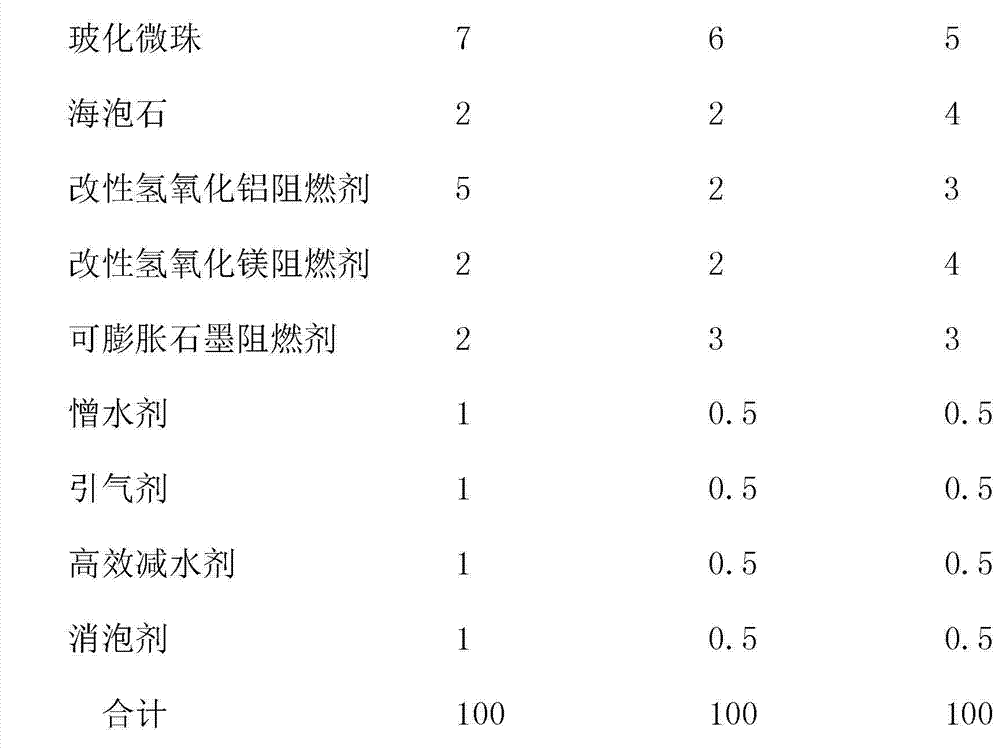

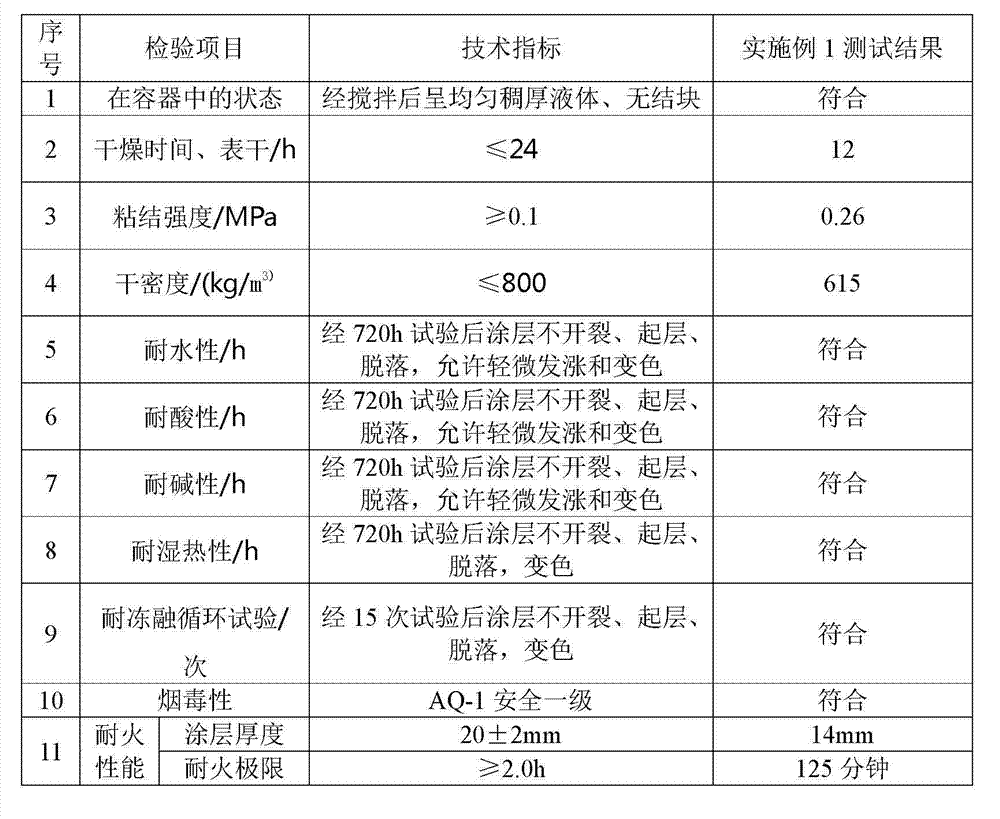

[0016] The present invention will be further described below in conjunction with specific examples (unit: weight %).

[0017]

[0018]

[0019] The Portland cement has excellent properties such as non-combustibility, water resistance, alkali resistance, durability, and weather resistance, and is the main binder component of thin tunnel fireproof coatings. Source of raw materials: commercially available.

[0020] The fireproof coating formed by the high alumina cement can still maintain high strength at high temperature, and the temperature resistance can reach 1300°C. The combination of high alumina cement and Portland cement makes the thin tunnel fireproof coating obtain the best strength and temperature resistance. Source of raw materials: commercially available.

[0021] The fly ash is solid waste discharged from coal-fired power plants, and its main components are SiO 2 、Al 2 o 3 etc. Add low-density, SiO-rich 2 The fly ash of the gelling agent can reduce the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com