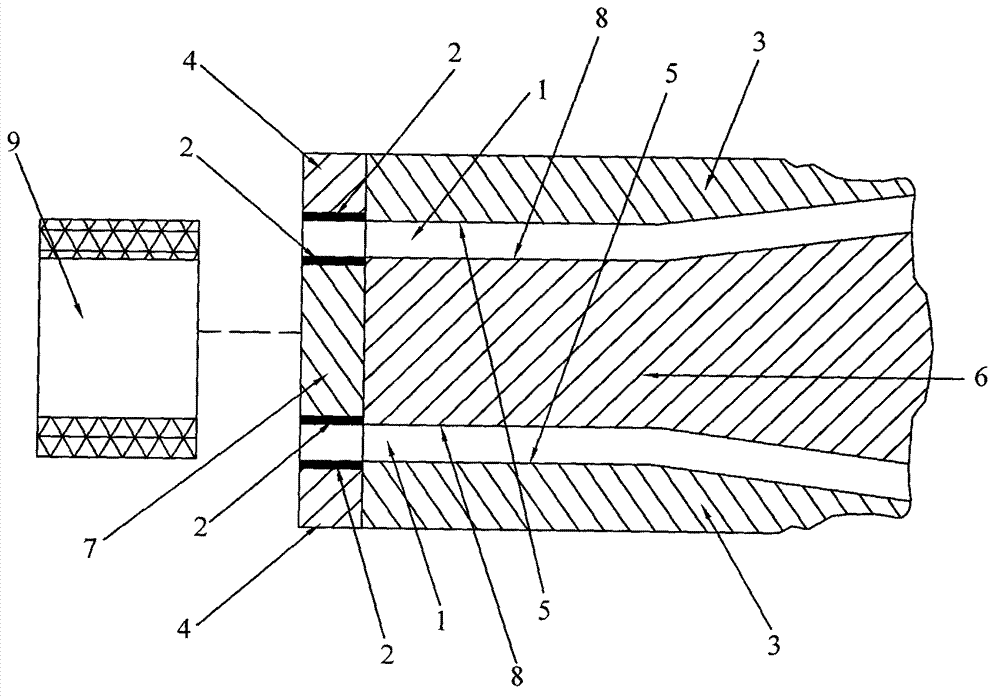

End die for extrusion die head of plastic pipe and manufacturing method of end die

A technology for extruding dies and plastic pipes, applied in the field of end dies and their manufacturing, can solve the problems of unsatisfactory finish of plastic pipes, and achieve the effect of improving finish, facilitating production and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

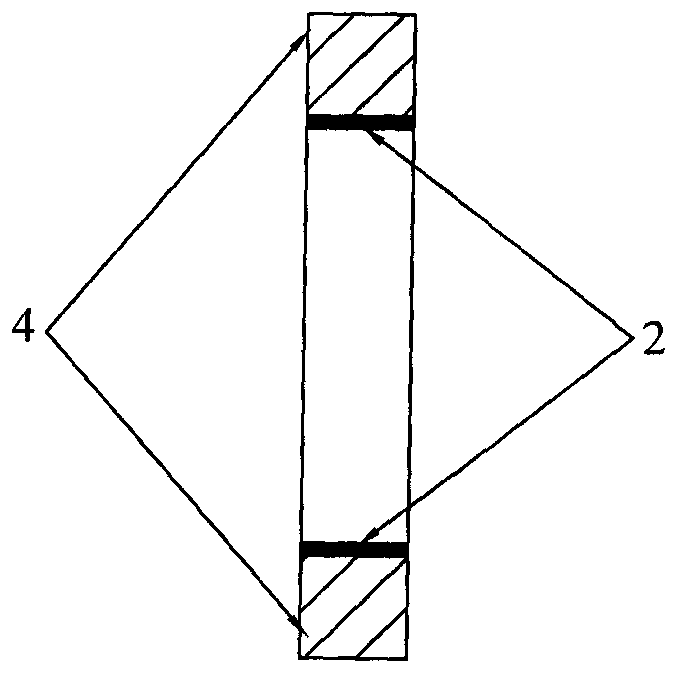

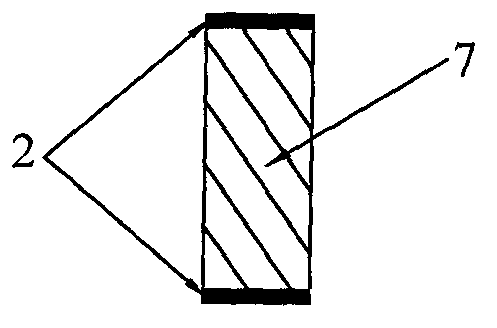

Method used

Image

Examples

Embodiment 1

[0034] The extruded plastic pipe is Φ110mm PP-R water supply pipe, the Teflon coating thickness of the port die and end mandrel is 0.30mm, the length of the port die and end mandrel is 20mm, and the material is pure PTFE Ethylene; the methods used include various spraying methods, such as polytetrafluoroethylene (PTFE) emulsion spraying and sintering film forming process, PTFE resin powder plasma direct spraying film forming process, etc. Since various spraying methods are mature processes and belong to general technologies, they will not be described in detail here. According to this embodiment, the extruded PP-R water supply pipe with a specification of Φ110 mm, according to the national standard GB / T1031-2009, has a surface roughness Ra of less than 0.8 μm.

Embodiment 2

[0036] The extruded plastic pipe is Φ630mm large-scale buried polyethylene (PE) pipe for gas, the Teflon coating thickness of the port die and end mandrel is 0.35mm, and the thickness of the port die connecting table and end mandrel connecting table is The length is 35mm, and the material of its Teflon coating is preferred for this embodiment. The material formula in parts by weight is: 97 parts of pure polytetrafluoroethylene, 0.3 part of leveling agent, 0.30 part of defoamer, lubricating 0.3 part, 0.25 parts of emulsifying agent and 18 parts of water, described polytetrafluoroethylene is all polytetrafluoroethylene emulsions that can be used on metal mould; , the preparation method is as follows:

[0037] (1) According to the Teflon water-based paint composed of the above materials, on the basis of 97 parts of pure polytetrafluoroethylene, defoamers, lubricants, leveling agents, and emulsifiers are successively added, and the defoamers can be divided into two types: joins; ...

Embodiment 3

[0042] The extruded plastic pipe is a Φ25mm plastic rod, and the outer cylindrical surface of the rod has a particularly high requirement for smoothness. The Teflon coating thickness is 0.25mm, the length of the port die is 75mm, the material of its Teflon coating is preferred for the present embodiment, and the material formula by weight parts is: 96 parts of pure polytetrafluoroethylene , 0.13 parts of leveling agent, 0.25 parts of defoamer, 0.3 parts of lubrication, 0.3 parts of emulsifier and 17 parts of water. The preparation method of the material formula is the same as in Example 2. According to this embodiment, the extruded Φ25mm plastic rod can achieve a surface roughness Ra of less than 0.8 μm according to the national standard GB / T1031-2009.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com