Silicon carbide (SIC) transverse Schottky junction type mini-sized nuclear battery and manufacturing method thereof

A Schottky junction and silicon carbide technology, which is used in nuclear engineering, obtaining electrical energy from radioactive sources, and applications of radiation from radioactive sources. and other problems, to achieve the effect of improving fill factor, improving energy conversion efficiency, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

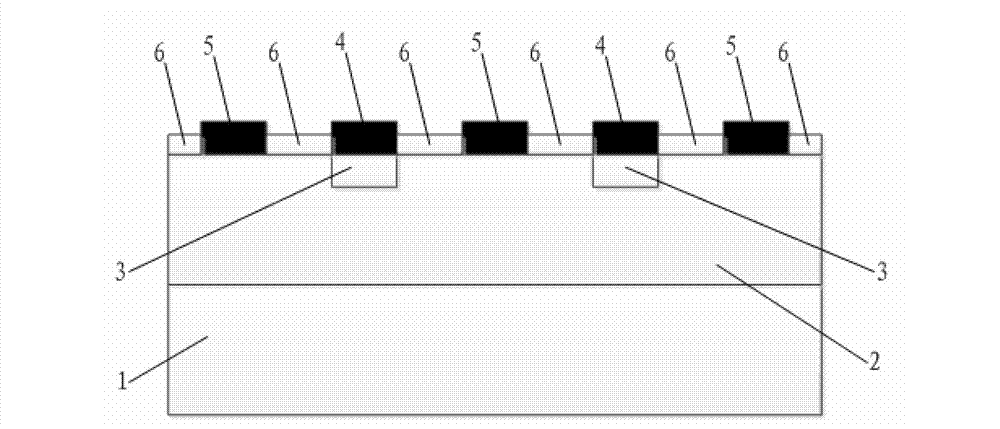

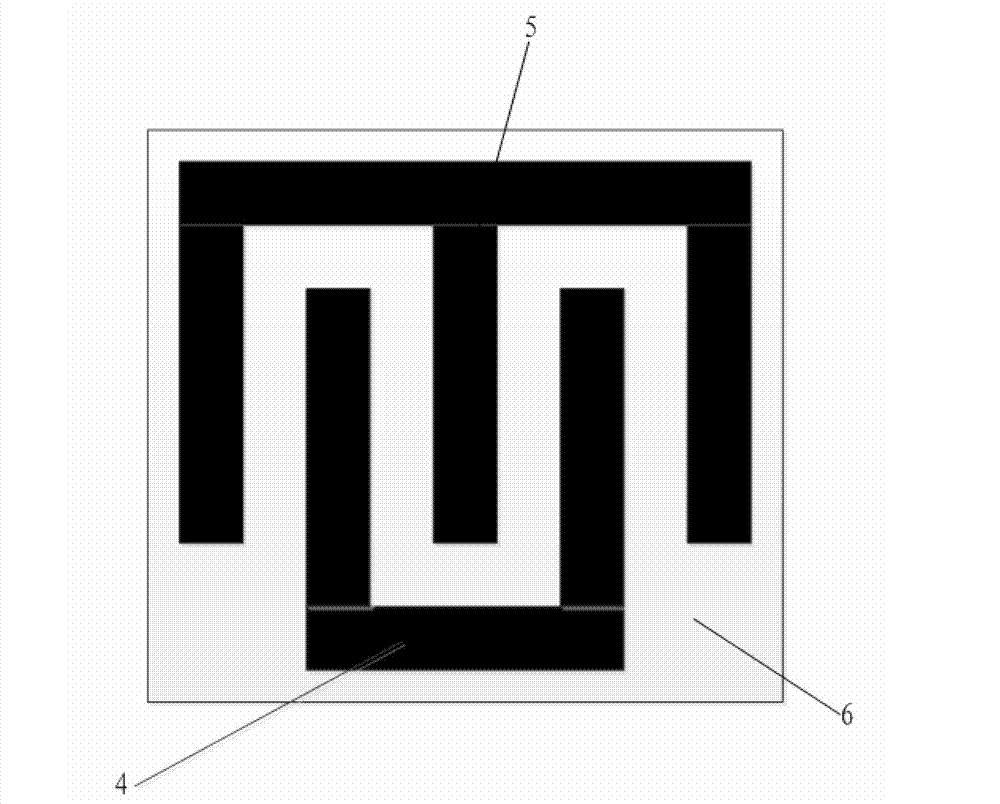

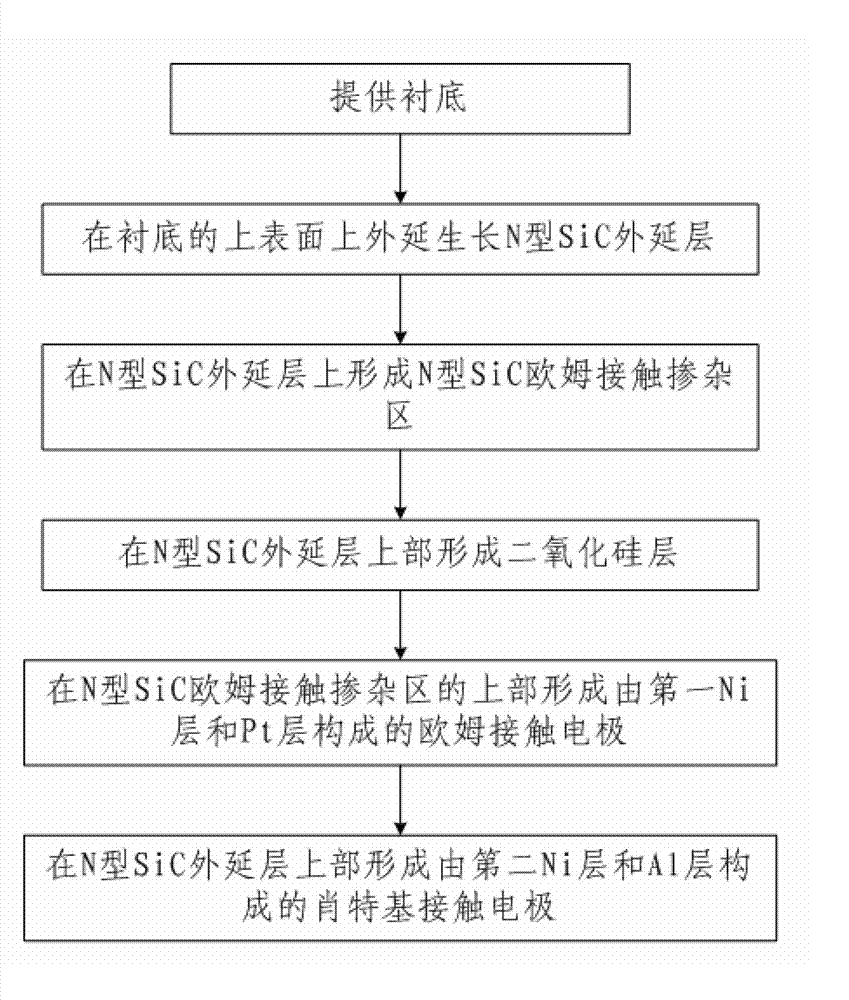

[0050] combine image 3 A method for manufacturing a silicon carbide lateral Schottky junction micro-nuclear battery according to the present invention, comprising the following steps:

[0051] Step 1: Provide a substrate 1, which is composed of an N-type SiC substrate; when step 1 is completed, the schematic diagram of the structure of a silicon carbide lateral Schottky junction micro-nuclear battery is as follows Figure 4a shown;

[0052] Step 2. Epitaxially grow on the upper surface of the substrate 1 with a doping concentration of 1×10 by using a low pressure hot wall chemical vapor deposition method. 15 cm -3 , N-type SiC epitaxial layer 2 with a thickness of 5 μm, the epitaxial growth temperature is 1570 ° C, the epitaxial growth pressure is 100 mbar, and the epitaxial growth gas is C with a volume ratio of 2:1:4 3 h 8 、SiH 4 and H 2 The mixed gas; the structure schematic diagram of silicon carbide lateral Schottky junction micro-nuclear battery when step 2 is com...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that in step 2, the epitaxial growth on the upper surface of the substrate 1 with a doping concentration of 3×10 15 cm -3 , an N-type SiC epitaxial layer 2 with a thickness of 6.5 μm; in step 3, an ion implantation method is used to form a doping concentration of 3×10 on the N-type SiC epitaxial layer 2 18 cm -3 The N-type SiC ohmic contact doped region 3, and thermal annealing at a temperature of 1565° C. for 10 minutes in an Ar atmosphere; in step 4, the N-type SiC epitaxial layer 2 is formed by dry oxygen oxidation at a temperature of 1150° C. The upper part is formed with a thickness of 15nm silicon dioxide layer 6; in step 5, electron beams are used to evaporate metal Ni and Pt successively in the first finger window, and 2 Perform thermal annealing at a temperature of 965° C. for 2 minutes in an atmosphere, and form an ohmic contact electrode 4 composed of a first Ni layer and a Pt layer on the upper par...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that in step 2, the epitaxial growth on the upper surface of the substrate 1 with a doping concentration of 5×10 15 cm -3 , an N-type SiC epitaxial layer 2 with a thickness of 8.5 μm; in step 3, an ion implantation method is used to form a doping concentration of 5×10 on the N-type SiC epitaxial layer 2 18 cm -3 The N-type SiC ohmic contact doped region 3, and thermal annealing at a temperature of 1580° C. for 10 minutes in an Ar atmosphere; in step 4, the N-type SiC epitaxial layer 2 is formed by dry oxygen oxidation at a temperature of 1150° C. The upper part is formed with a thickness of 20nm silicon dioxide layer 6; in step 5, electron beams are used to evaporate metal Ni and Pt successively in the first finger window, and 2 Perform thermal annealing at a temperature of 985° C. for 2 minutes in an atmosphere, and form an ohmic contact electrode 4 composed of a first Ni layer and a Pt layer on the upper par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com