Liquid level control device used in high temperature condition

A liquid level control and high temperature environment technology, applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve problems such as difficulty in adapting to harsh environments, component failure, and difficult sealing of rubber components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

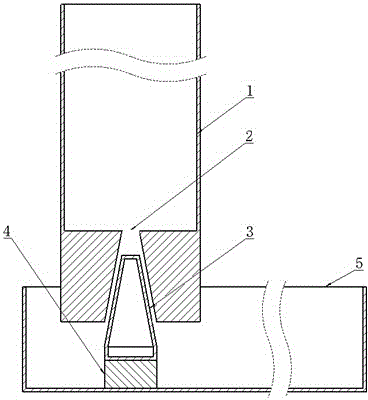

[0032] The objective of this example is liquid control of molten gallium metal taken at 600°C.

[0033] The whole device is made of quartz material, and the structure of the whole device is as attached figure 1 As shown, the liquid metal source containment area 1 is located above the structure. At this time, the liquid metal source containment area 1 is a liquid metal gallium source containment area, and the shape of the sealing module 3 is a conical hollow shell with a small top and a large bottom. Take a matte finish. The control module 4 is a heavy block, and the control module 4 is connected with the bottom of the sealing module 3 . Above the sealing module 3 is the liquid inlet channel 2, the shape of the liquid inlet channel 2 corresponds to the shape of the sealing module 3, and the wall surface of the channel 2 is frosted. The weight is immersed in the middle of the liquid tank 5 .

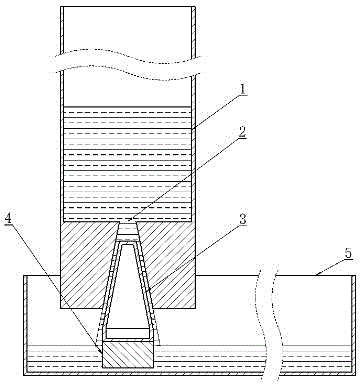

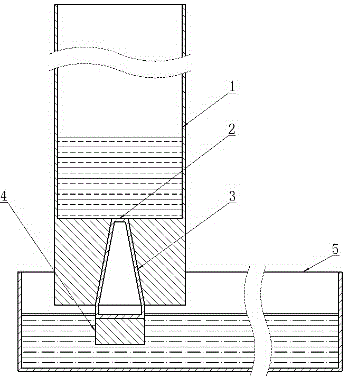

[0034] as attached figure 2 As shown, when the liquid level of metal gallium in t...

Embodiment approach 2

[0036] The purpose of this example is to control the liquid level of molten metal calcium at 1000 °C, and the entire device is made of alumina ceramics.

[0037] as attached Figure 4 As shown, the liquid metal source accommodation area 1 is now the molten metal calcium source accommodation area, the liquid metal source accommodation area 1 (molten metal calcium source accommodation area) is on the side of the liquid tank 5, the liquid metal source accommodation area 1 (molten metal calcium source accommodation area) Source containing area) communicates with the liquid tank 5 through a liquid inlet channel 2 at the bottom. The control module 4 is a spherical shell with a connecting rod on the spherical surface. The connecting rod is connected to the sealing module 3 through the liquid inlet channel 2 at the bottom of the liquid tank 5 The liquid inlet channel 2 is processed with a boss in the outward direction. The sealing module 3 is a bowl-shaped boss.

[0038] as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com