Intubation pipe type gas-liquid separator based on differential pressure balance

A gas-liquid separator and intubation-type technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as hysteresis, high pressure, and narrow oil well holes, and achieve reduced impact height and strength, Improvement of gas-liquid separation efficiency and the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

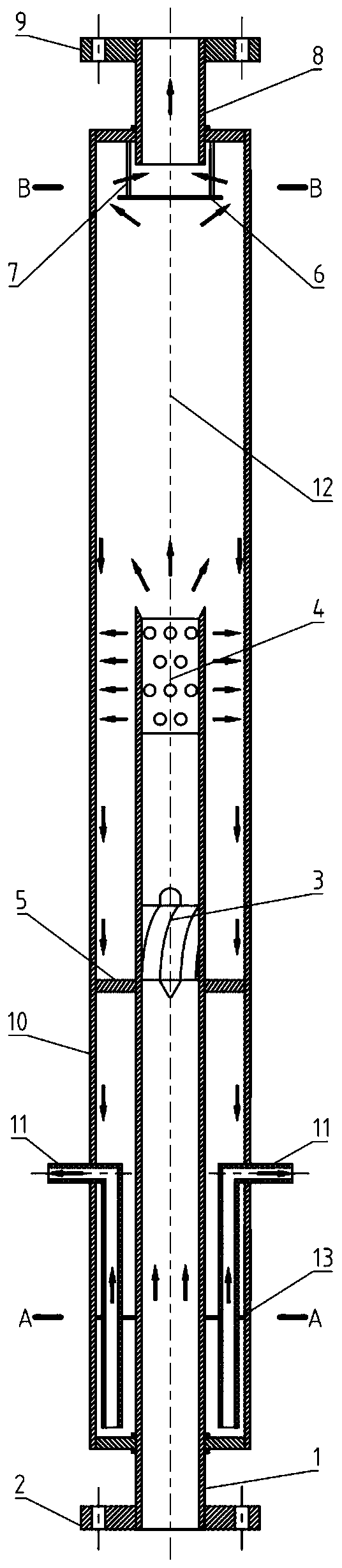

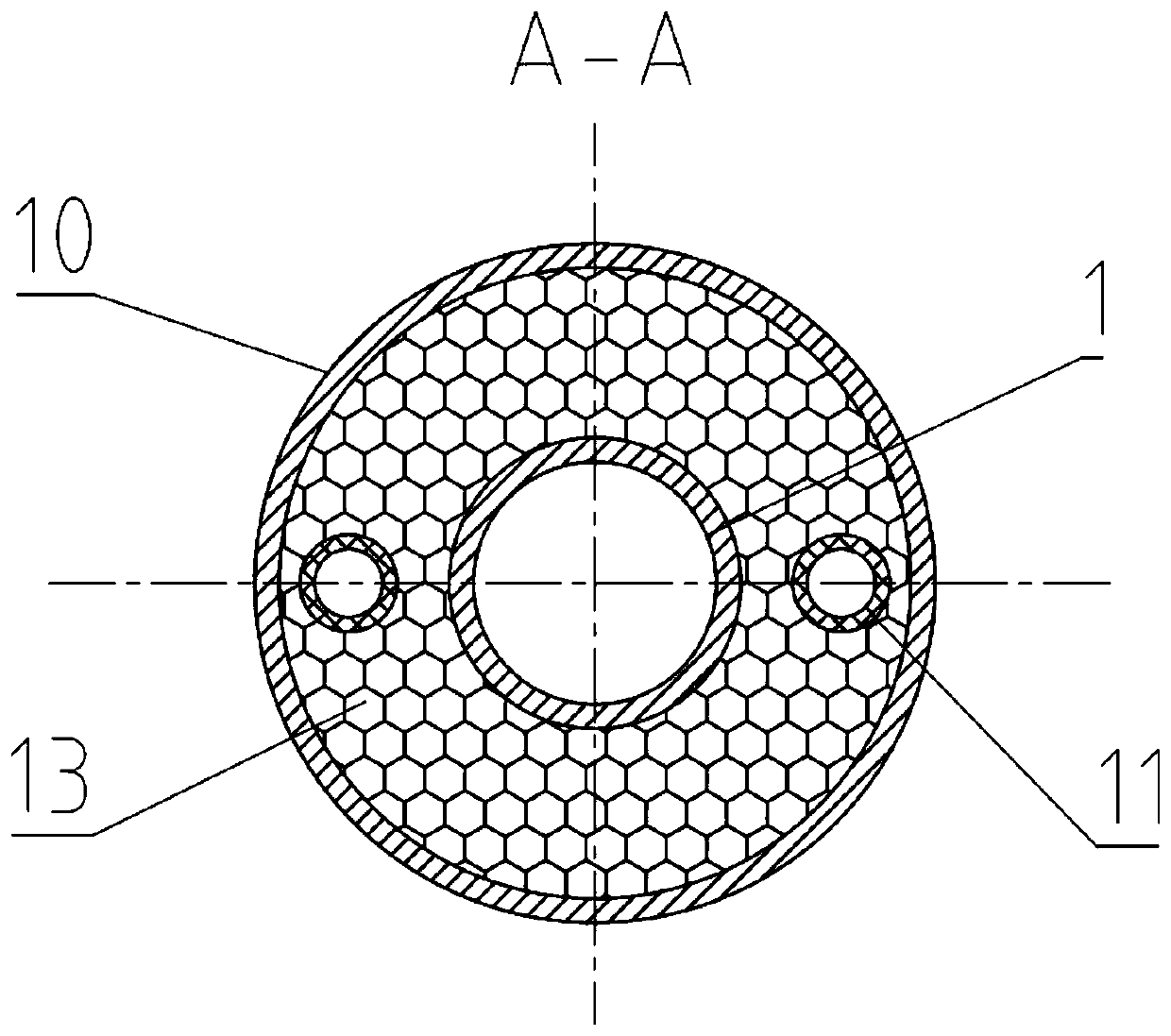

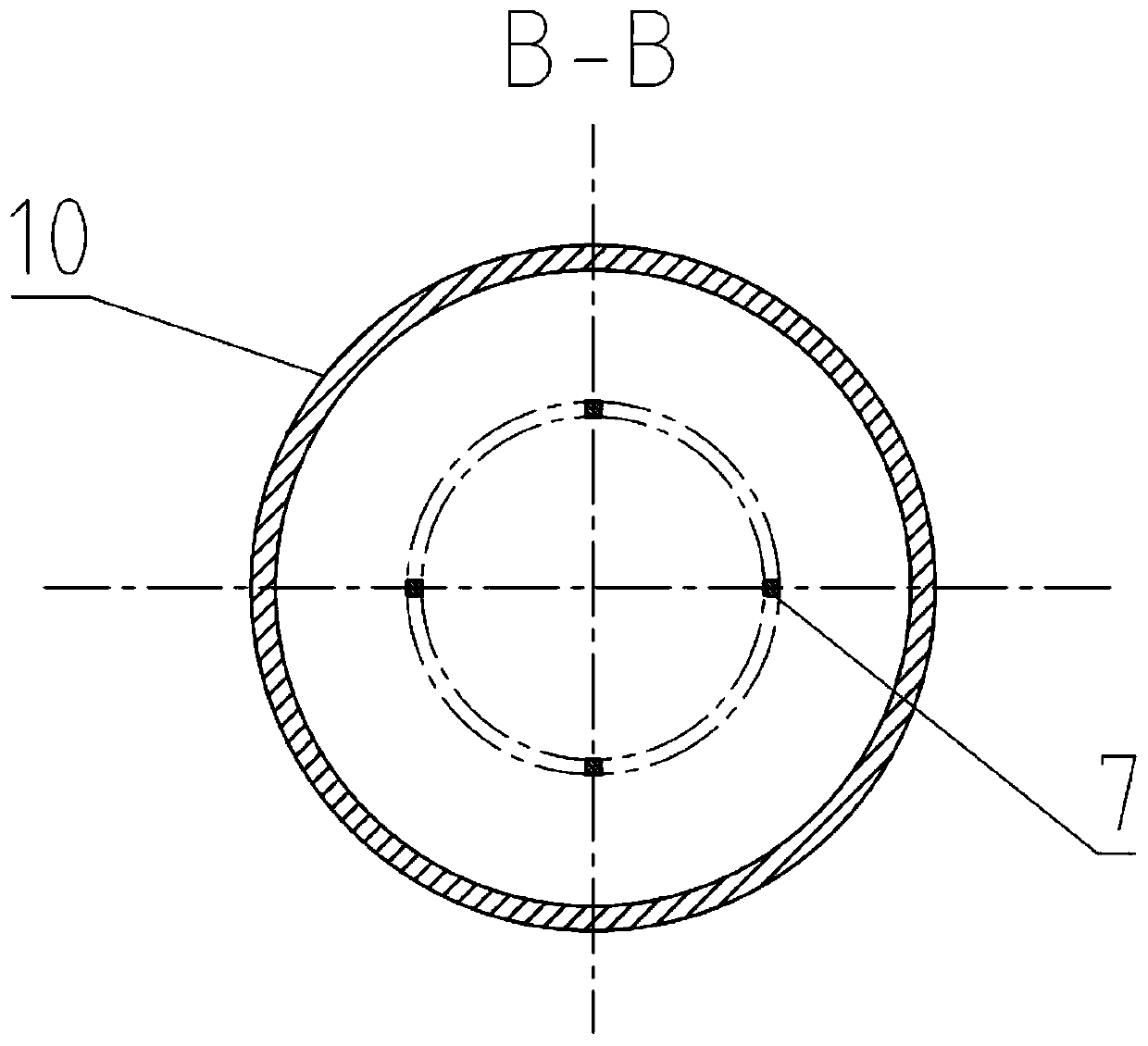

[0038] Embodiment 1: Combination Figure 1-3 , The main structure of the separator is composed of cylinder structures nested in each other, namely: outer cylinder 10, core cylinder 1, the gas-phase outlet 8 of the separator is located at the top of the outer cylinder 10; the lower part of the gas-phase outlet 8 is provided with water blocking The plate 6 is fixed to the top cover of the outer cylinder 10 by the connecting rod 7; the upper part of the core cylinder 1 is provided with a drainage section 4, and the drainage section 4 is provided with a drainage hole; in the core cylinder 1 and the outer cylinder 10 ring cavity The lead pipe 11 is arranged in a middle ring shape, and the lead pipe 11 is led out from the wall surface of the outer cylinder 10. A filter screen 13 is provided at the lower part of the annular cavity of the core cylinder 1 and the outer cylinder 10. A development section 4-10 times the inner diameter of the core barrel 1 is reserved between the drainage...

Embodiment approach 2

[0043] Embodiment 2: Combination Figure 4 On the basis of Embodiment 1, the separator structure is appropriately adjusted, and the impeller is improved into two impellers 23 and two-stage impeller 14. The first-stage impeller 23 is installed in the core tube 1, and the upper part of the core tube 1 is provided with a row In the liquid section 4, a secondary impeller 14 is installed at the outlet of the core tube 1. Attached Figure 4 , To further describe the implementation in detail:

[0044] Combine Figure 4 , The present invention provides an intubation type gas-liquid separator based on pressure difference balance, including: core tube 1, inlet flange 2, impeller 23, drain section 4, shock-proof strip 5, water baffle 6, connection The rod 7, the separator gas phase outlet 8, the outlet flange 9, the outer cylinder 10, the outlet pipe 11, the gravity separation chamber 12, the filter screen 13, and the secondary impeller 14.

[0045] When performing gas-liquid separation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com