Wide-flow-path highly-efficient gas-liquid separator controlled by utilizing buoy

A technology of gas-liquid separator and buoy, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as hysteresis, high pressure, and narrow oil well holes, and reduce the impact height and strength, and weaken the shaft The impact and the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

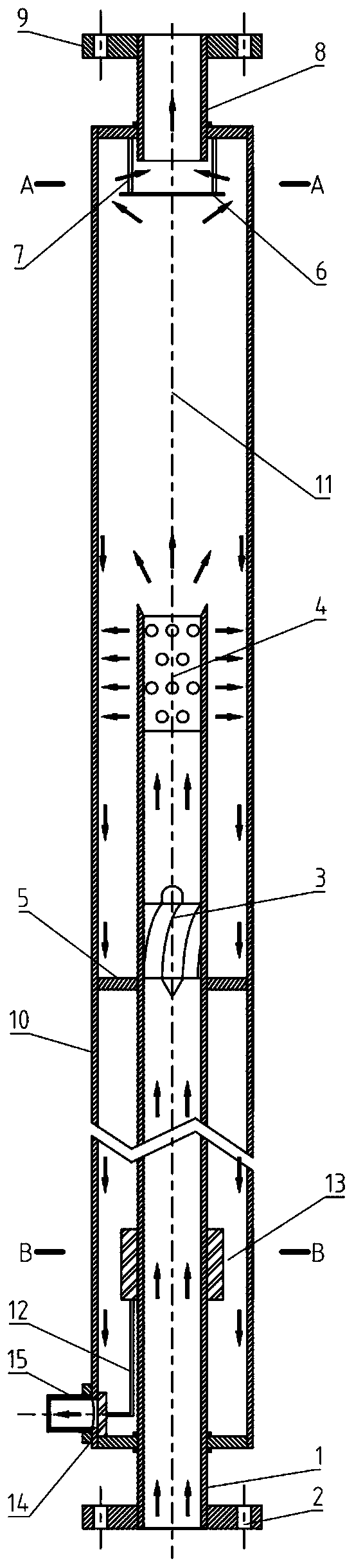

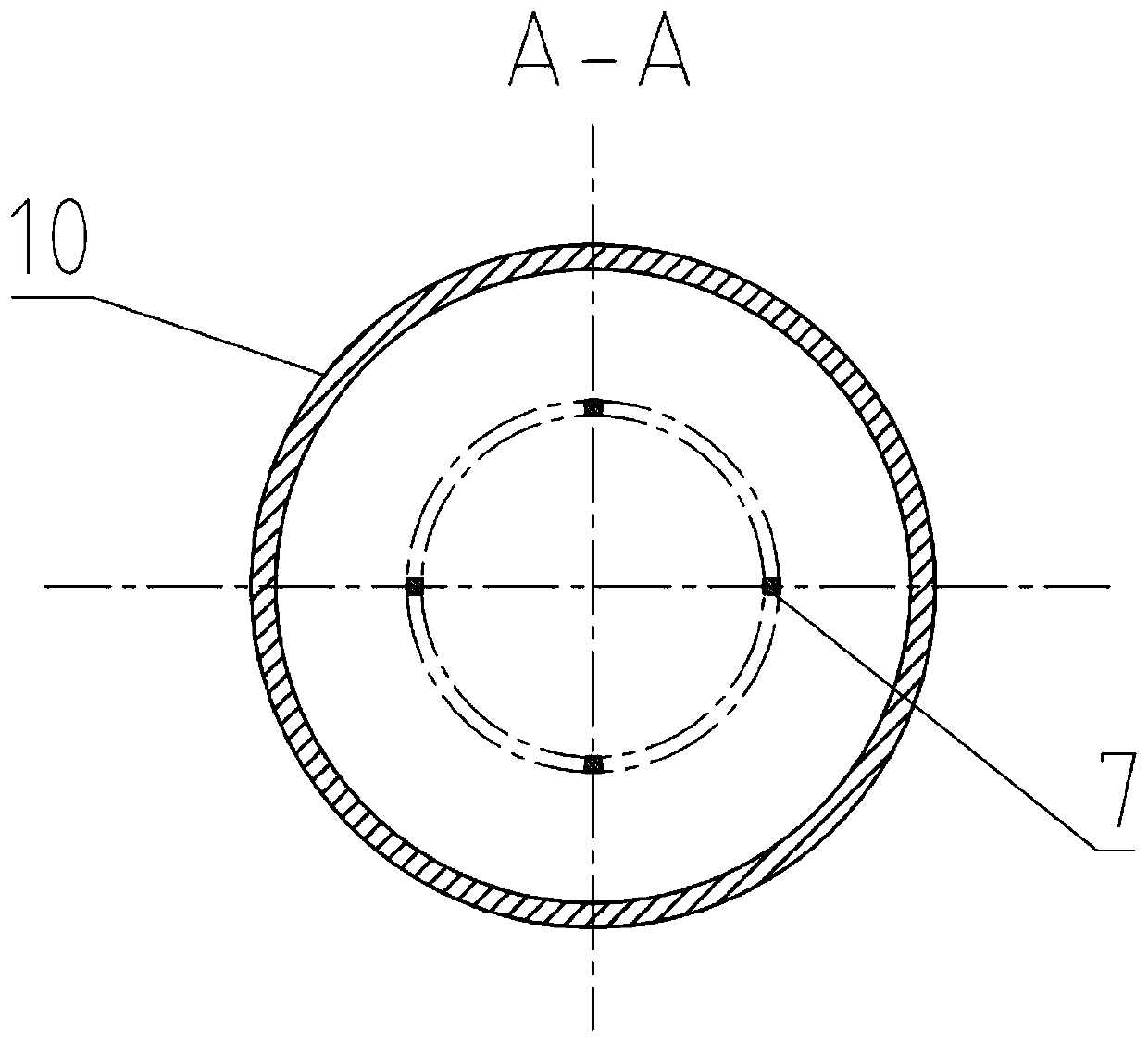

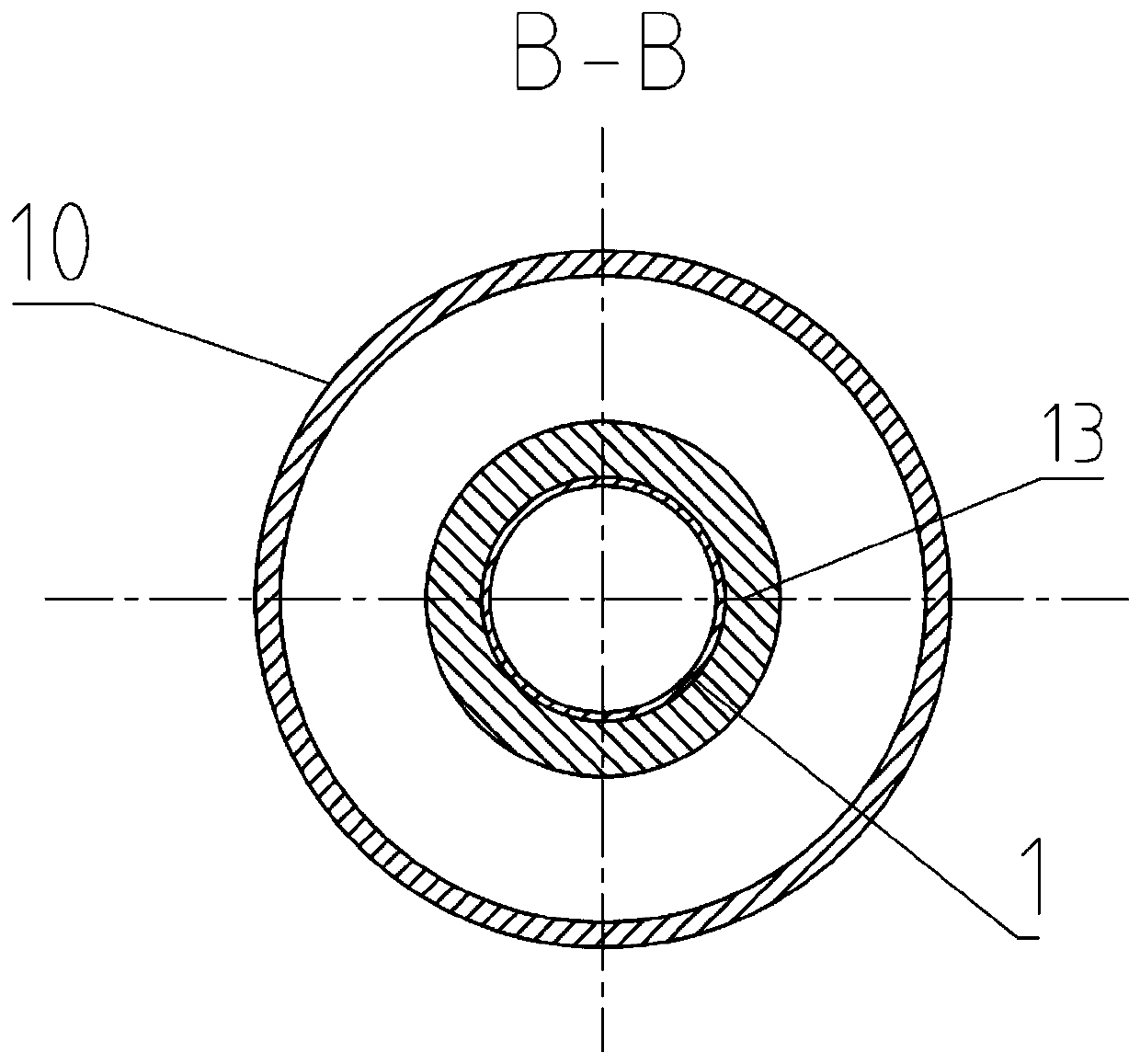

[0034] Embodiment 1: Combining Figure 1-3 , the main structure of the separator is composed of mutually nested cylinder structures, namely: the core cylinder 1, the outer cylinder 10, the separator 11, the connecting shaft 12, the movable buoy 13, the gas phase outlet 8 and the liquid phase outlet 15 of the separator They are respectively located at the top and lower part of the outer cylinder 10; a water barrier 6 is provided at the lower part of the gas phase outlet 8, and is fixed on the top cover of the outer cylinder 10 by a connecting rod 7; a liquid discharge section 4 is provided at the upper part of the core cylinder 1 to discharge A liquid discharge hole is opened in the liquid section 4; an impeller 3 is placed at the lower part of the liquid discharge section 4 in the core tube 1; A partition 11 is set and connected by a connecting shaft 12; a development section 4 to 10 times as long as the inner diameter of the core barrel 1 is reserved between the liquid discha...

Embodiment approach 2

[0046] Embodiment 2: Combining Figure 4 , on the basis of Embodiment 1, the structure of the separator is properly adjusted, and the outlet tube 17 is added, and the water blocking cap 18 is installed on the upper end of the core tube 1 through the water blocking cap support bars 19, and there is a The air outlet 17 is located inside the outer cylinder 10, the lower part of the air outlet 17 is located in the core barrel 1, the upper part of the air outlet 17 passes through the water blocking cap 18 and is located in the gravity separation chamber 11, and the upper part of the air outlet 17 is covered with a water retaining ring 16, The water retaining ring 16 is connected to the inner wall of the outer cylinder 10 . combined with Figure 4 , to further describe the implementation in detail:

[0047] combine Figure 4 , a wide-flow high-efficiency gas-liquid separator controlled by buoys provided by the present invention includes: 1 core cylinder, 2 inlet flange, 3 impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com