Active liquid level control gas-liquid separator by using gravity ball

A gas-liquid separator and liquid level control technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of hysteresis, small oil well holes, high pressure, etc., and reduce the impact height and strength, Improve separation efficiency and weaken the effect of axial impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

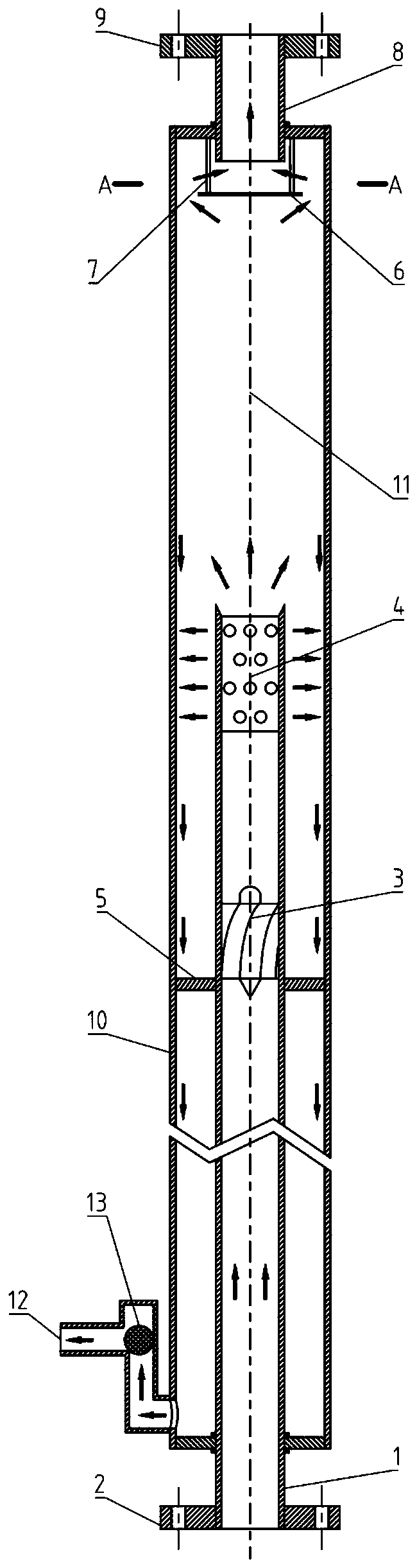

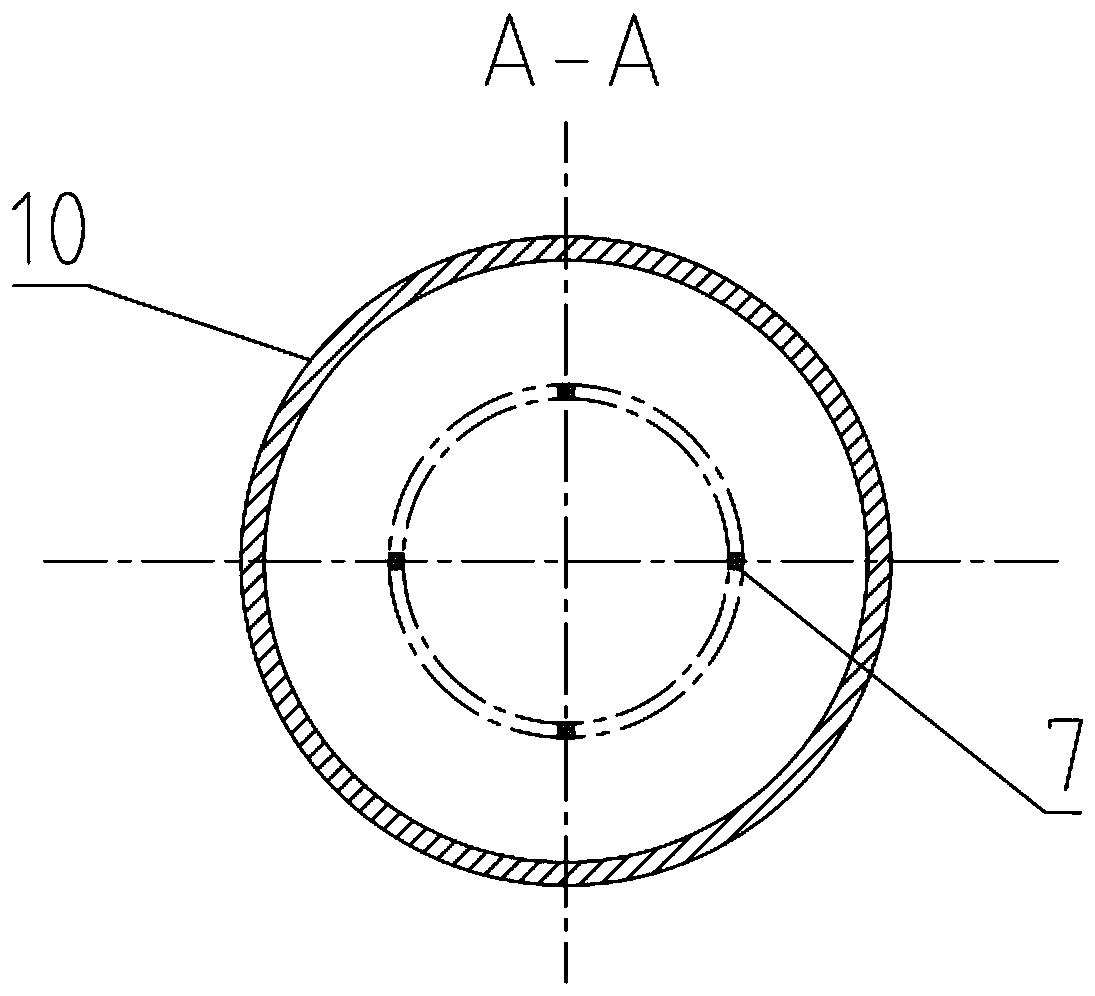

[0034] Embodiment 1: Combining Figure 1-2 , the main structure of the separator is composed of: an inner cylinder 1, an outer cylinder 10, and a gravity ball 13. The gas phase outlet 8 and the liquid phase outlet 12 of the separator are respectively located at the top and bottom of the outer cylinder 10; the gravity ball 13 is located in the liquid phase In the outlet 12, an activity area is reserved above it; the liquid phase outlet 12 is connected to the bottom of the outer cylinder 10 by the principle of a connector; a water barrier 6 is arranged below the gas phase outlet 8, and is fixed on the outer cylinder 10 by a connecting rod 7 Top; the upper part of the inner cylinder 1 is provided with a drainage section 4, and a drainage hole is opened in the drainage section 4; a gravity separation chamber 11 is arranged above the outlet of the inner cylinder 1; an impeller is arranged under the drainage section 4 3. A development section 4 to 10 times as long as the inner diam...

Embodiment approach 2

[0050] Embodiment 2: Combining image 3 , On the basis of Embodiment 1, the outlet cylinder 15 is added, and the impeller 3 is changed to a first-stage impeller 23 and a second-stage impeller 33 . A primary impeller 23 is installed in the inner tube 1, and a secondary impeller 33 is installed in the outlet of the inner tube 1. The outlet tube 15 is a transparent structure, and the outlet tube 15 is located above the inner tube 1 and below the water retaining plate 6. A water-shielding ring 14 is installed on the outside of the lower end of the outlet tube 15, and at least one separation orifice is installed on the outside of the outlet tube 15, and the separation orifice is connected to the outer The inner wall of the cylinder 10.

[0051] When performing gas-liquid separation, the technical solution is: the body of the separator is installed and fixed through the inlet flange 2 and the outlet flange 9 . The gas-liquid mixture enters the separator from the inlet port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com