Waveguide coupler with echelon grating mirror and preparation method thereof

A kind of echelle grating and reflector technology, applied in the coupling of optical waveguide, optical waveguide light guide, light guide, etc., can solve the problems of not meeting the requirements of optical communication, polarization-related loss, large device size, etc., and reduce the spatial orientation of the beam And the effect of extremely high position, reduced energy loss, and large alignment tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

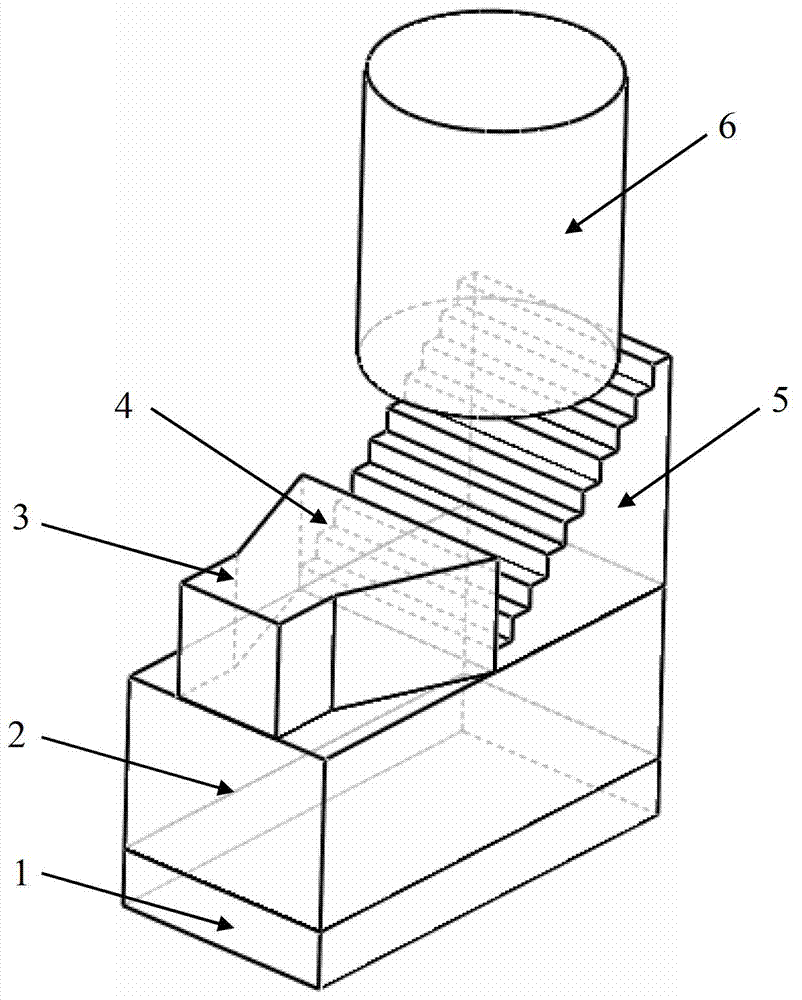

[0030] The above-mentioned preparation method of the waveguide coupler with the stepped grating reflector comprises the following steps:

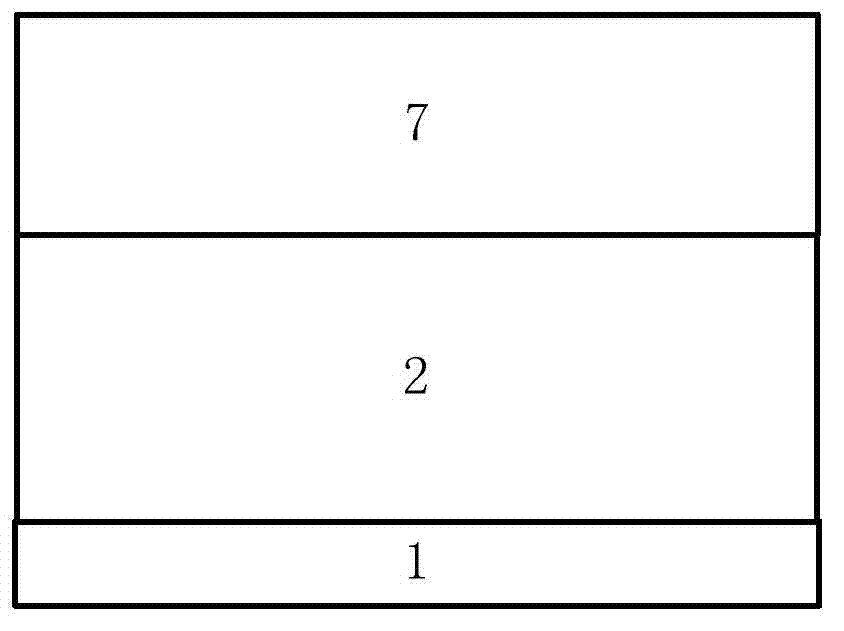

[0031] Step 10): Take a silicon substrate 1, and prepare a silicon dioxide buffer layer 2 with a thickness of 15 μm to 20 μm on the silicon substrate 1; Growth doped germanium dioxide (GeO 2 ) silicon dioxide to form a waveguide layer 7 with a thickness of 6 μm-10 μm, and the refractive index of the waveguide layer 7 is higher than that of the buffer layer 2 .

[0032] Step 20): On the waveguide layer 7, the photolithography and etching processes are repeatedly used to prepare the grating reflector 5.

[0033]In step 20), the photolithography refers to copying the pattern of the mask onto the waveguide layer 7, and after each photolithography, an etching process is performed respectively to prepare the grating reflector 5.

[0034] Step 30): On the waveguide layer 7, the tapered waveguide 4 is prepared by photolithography and etching.

...

Embodiment

[0038] A preparation method of a polarization-maintaining planar lightwave optical path is introduced below to describe the above preparation method in more detail.

[0039] Step 10): making the silicon dioxide buffer layer 2 and the waveguide 7 . refer to image 3 As shown, firstly, the silicon wafer, that is, the substrate 1, is cleaned by wet chemical method to remove the dirt on the surface; then, after ultrasonic cleaning and drying of deionized water, the cleaning of the silicon wafer is completed; next, the silicon dioxide buffer is prepared Layer 2, there are many methods for preparing the silica buffer layer 2, such as chemical vapor deposition (CVD), flame hydrolysis (FHD), sol-gel (Sol-Gel), thermal oxidation (TO) and so on. Since the thermal oxidation method can oxidize more than one hundred silicon wafers at the same time, it has higher efficiency in actual production, and can simultaneously oxidize the front and back sides of the silicon substrate 1, thereby eli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com