Variable-angle high-temperature heat testing device for conical housing with oblique section of high-speed aircraft

A high-speed aircraft, oblique section technology, applied in measuring devices, testing of machine/structural components, instruments, etc., can solve problems affecting the reliability of test safety test results, damage to the electrode of the quartz lamp heating tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

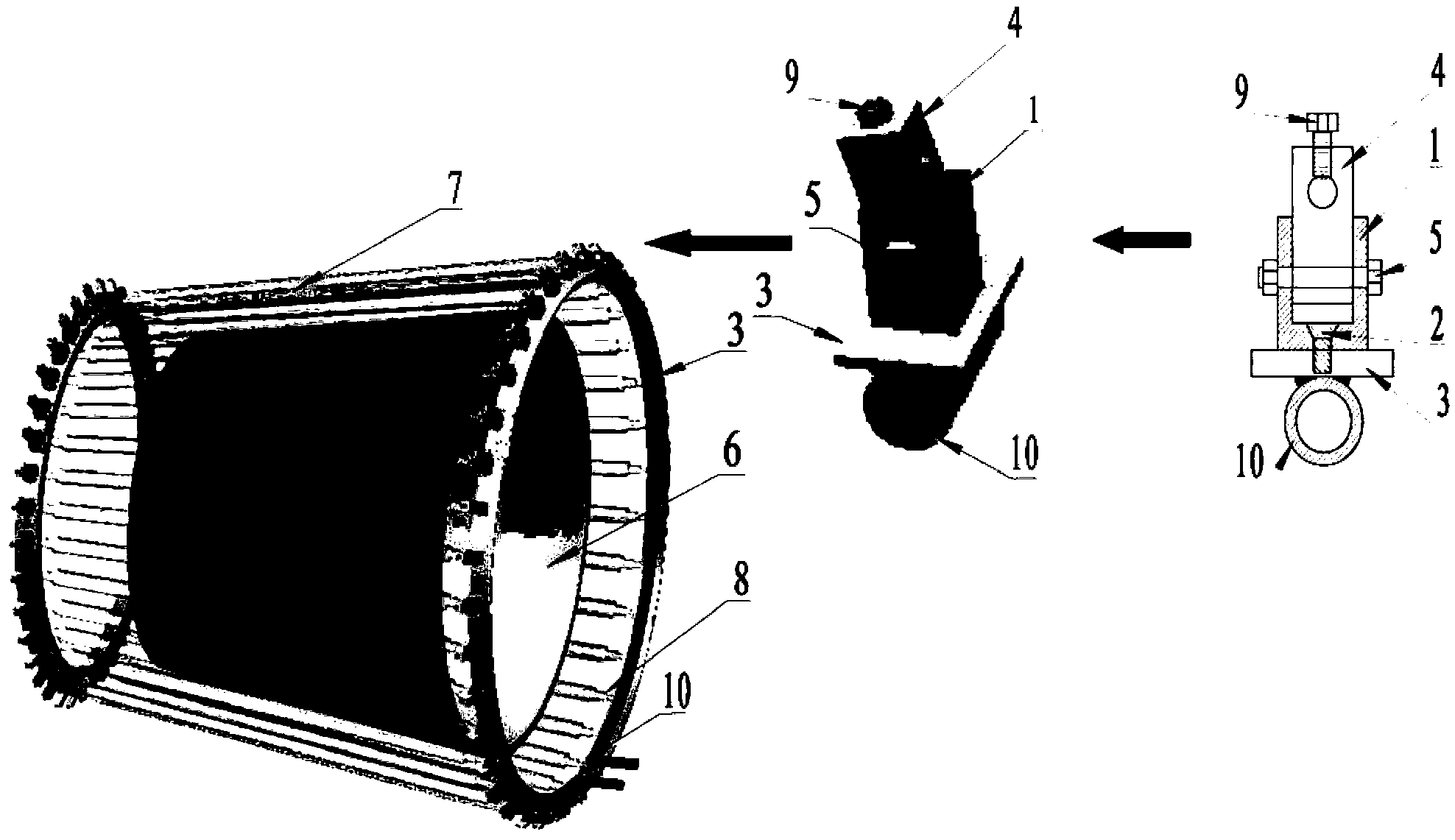

[0022] Such as figure 1 As shown, the present invention consists of a U-shaped copper support 1, a tapered fastening screw 2, an annular flat copper support 3, an adjustable electrode support 4, a connecting locking shaft 5, a high-speed aircraft oblique section conical shell 6, Quartz lamp heating tube 7, quartz lamp heating tube electrode 8, electrode top wire 9 and water-cooled copper tube 10 are composed. The U-shaped copper support 1 is fixed on the ring-shaped flat copper support 3 by the conical fastening screw 2, and the adjustable electrode support 4 is connected with the U-shaped copper support 1 by connecting the locking shaft 5. There are two ring-shaped flat copper brackets 3 with different diameters on the outside of the two ends of the conical shell 6. U-shaped copper supports 1 with equal numbers are installed on each ring-shaped flat copper bracket 3, and there are 7 pairs of quartz lamp radiation heating tubes. The heating tube electrode 8 at the end is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com