An antistatic structure of an electronic detonator

An electronic detonator and anti-static technology, used in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of the existence of electronic detonator structure, no electrical connection, inability to discharge, etc., to ensure anti-static, prevent false explosion, and resist tension strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

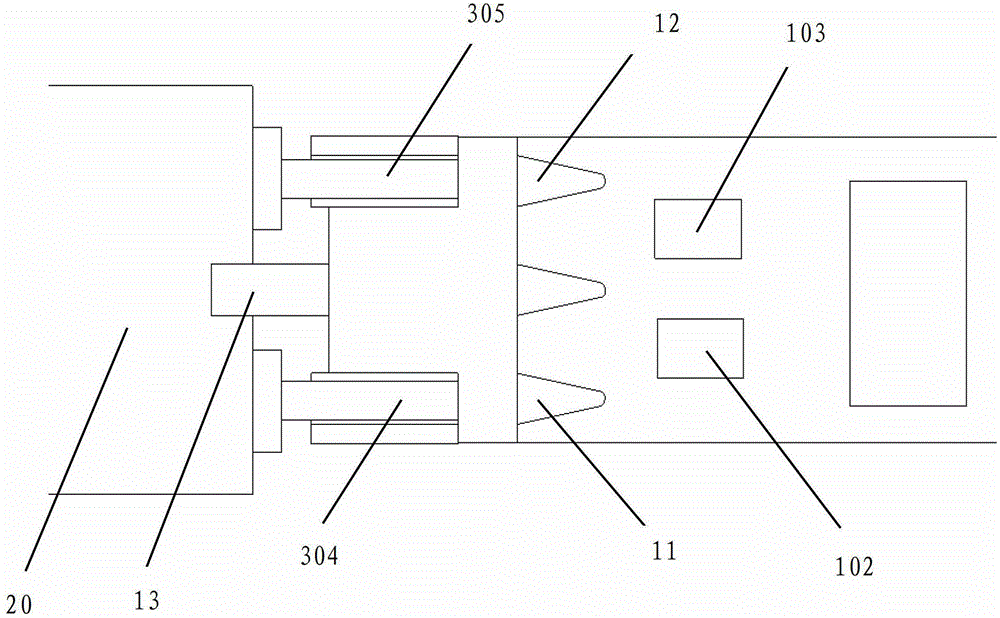

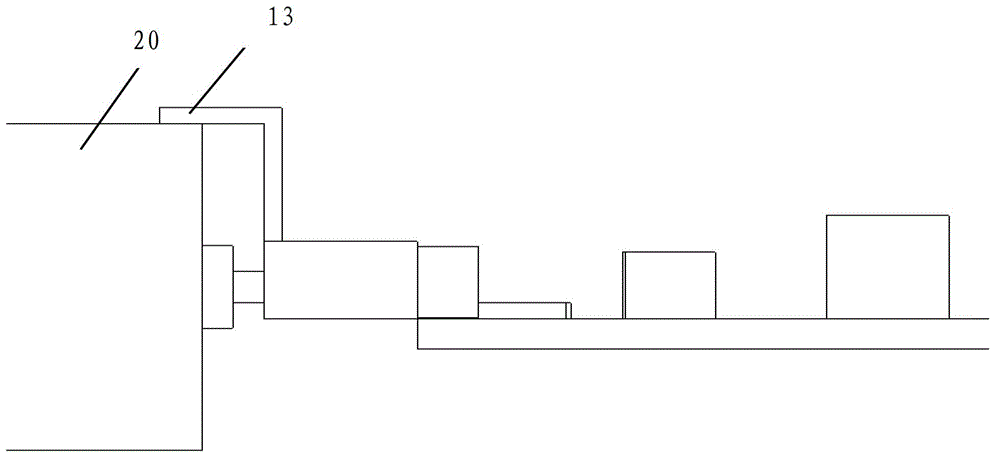

[0025] see figure 1 , figure 2 , image 3 As shown, the antistatic structure of the electronic detonator provided by the present invention is mainly applicable to parallel electronic detonators. Connectors 12 and discharge metal connectors 13 (both sheets in this embodiment), the first and second metal connectors 11, 12 are respectively connected between the two legs 304, 305 and the control circuit The control circuit 303 of the board 300 (as Image 6 As shown), one end of the discharge metal connector 13 is fixed on the control circuit 303 board 300, and the other end is close to the cylindrical surface of the insulating sealing plug 20 closest to the control circuit board and the metal shell 302 of the electronic detonator (such as Image 6 Shown) the inner wall of the conductive connection.

[0026] Such as Figure 4 , Figure 5 As shown, the three metal connectors 11, 12, 13 are insulated from each other, and are integrated by injection molding of high-resistance m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com