LED (Light Emitting Diode) bulb structure

A technology of LED light bulbs and LED light sources, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problem of bulky structure, can not solve the heat conduction and heat dissipation components and the contact area of the lamp board, can not solve the problem of heat conduction and insulation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

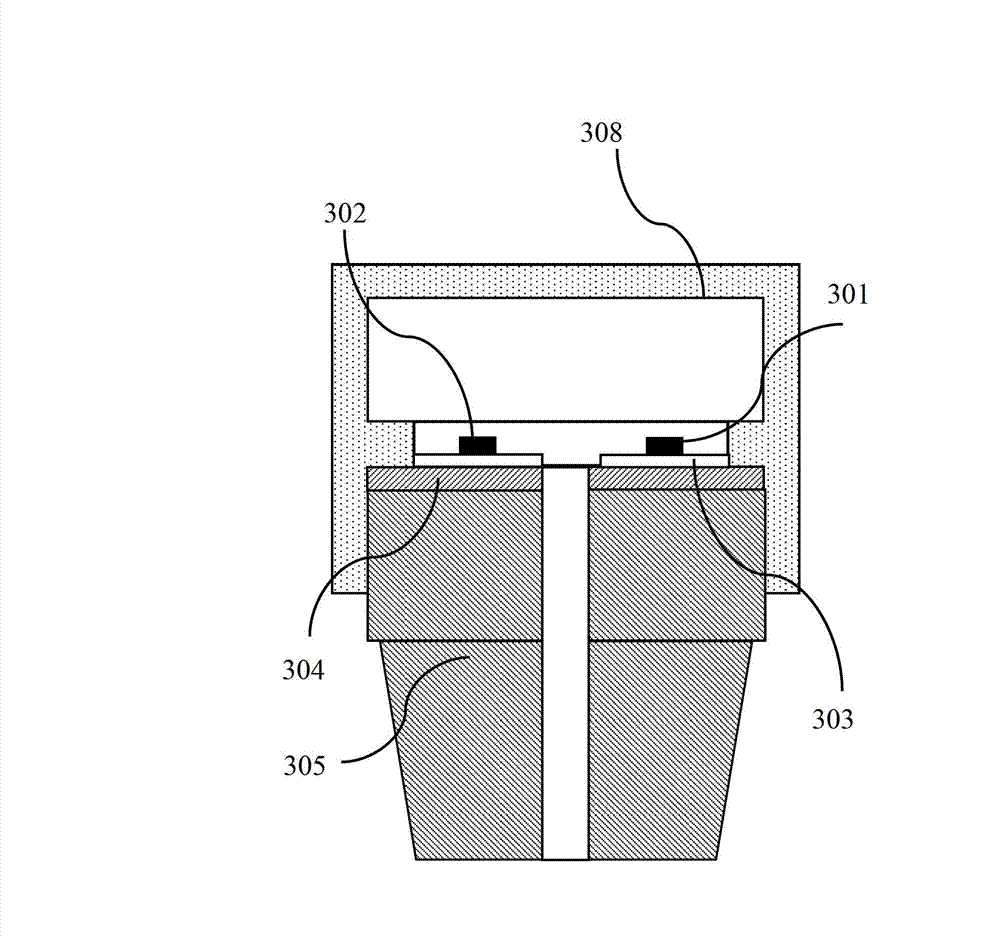

[0122] Such as Figure 6 Shown is the third embodiment of the present invention, an LED bulb structure for manufacturing LED bulbs, lamp tubes, lamp panels, and various LED lighting modules, including a lampshade 601, an LED chip 602, a lampshade and a substrate Fastening sealing ring 603, base plate 604, heat conduction liner 605, heat sink 606 and heat pipe 607 forming heat dissipation body, heat conduction channel 608, heat conduction channel through hole 610, insulating support 609a, insulating sleeve inner cavity 611, lamp cap 612, lamp cap Lumen 613 and so on. The driving power supply and / or the control circuit 620 may be disposed on the substrate 604 , and / or in the through hole 610 of the heat conduction channel, and / or in the inner cavity 611 of the insulating sleeve, and / or in the inner cavity 613 of the lamp cap.

[0123] Compared with the second embodiment, in this embodiment, the heat conduction channel 608 is connected to the lamp cap 612 through the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com