Energy-saving shield segment assembling and positioning electro-hydraulic control system adopting load-sensitive technology

An electro-hydraulic control system and technology of shield segments, which are applied in mining equipment, shaft equipment, earth-moving drilling, etc., can solve the problems of deterioration of tunnel construction environment, low system efficiency, and impact on equipment life, etc., and achieve outstanding energy-saving effect. Achieve precise control and improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

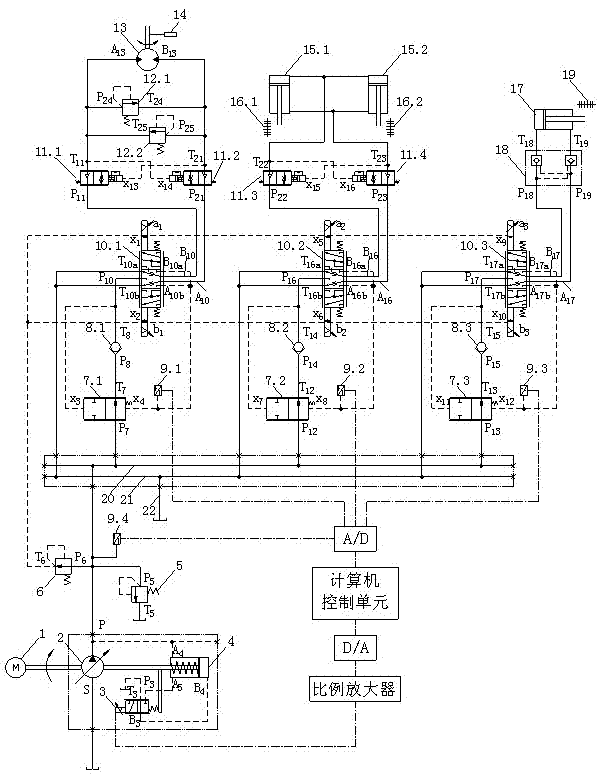

[0015]As shown in the accompanying drawings, an energy-saving shield segment assembly and positioning electro-hydraulic control system using load-sensing technology is characterized in that it includes: motor 1, variable pump 2, two-position three-way proportional reversing valve 3, variable cylinder 4. The first relief valve 5, the pressure reducing valve 6, the first pressure compensation valve 7.1, the second pressure compensation valve 7.2, the third pressure compensation valve 7.3, the first one-way valve 8.1, the second one-way valve 8.2, the second Three check valves 8.3, first pressure sensor 9.1, second pressure sensor 9.2, third pressure sensor 9.3, fourth pressure sensor 9.4, first multi-way valve 10.1, second multi-way valve 10.2, third multi-way valve 10.3 , first balance valve 11.1, second balance valve 11.2, third balance valve 11.3, fourth balance valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com