Polymer film and its application in a lighting assembly

A technology of polymer film and light-emitting device, which is applied in parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of yellowing, high reflectivity, low penetration, etc., and achieve improvement of yellowing , High reflectivity, low penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

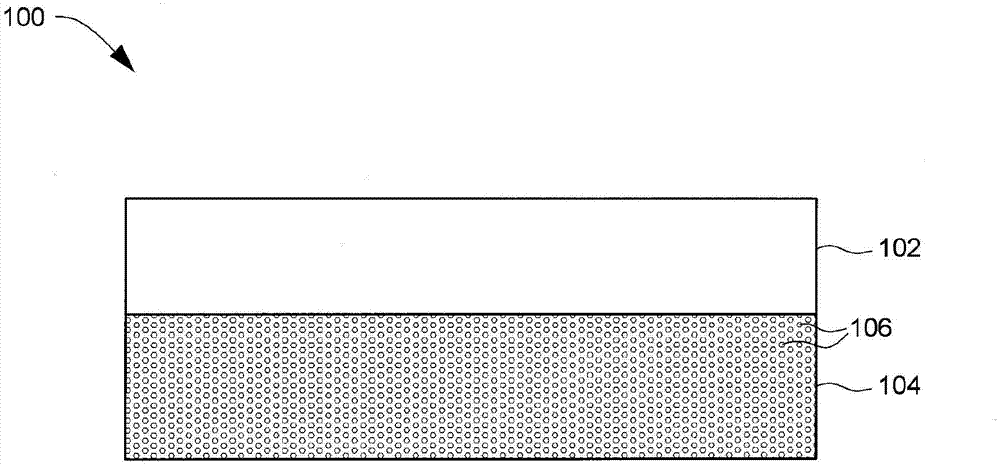

[0038] Preparation of polyimide film

Synthetic example 1

[0040] Nitrogen gas was fed into a 500 milliliter (ml) three-necked flask as the polymerization vessel at ambient temperature. All reactions were performed under nitrogen atmosphere. About 160 grams (g) of dimethylacetamide (DMAC) as solvent was added to the flask. About 18.774 g (0.060 mole) of 2,2'-bis(trifluoromethyl)benzidine (TMFB) was dissolved in DMAC. After TMFB is completely dissolved in DMAC, add about 13.354g (0.045moles) of biphenyltetracarboxylic dianhydride (BPDA) and about 7.873g (0.015moles) of 2,2-bis[4-(dicarboxyphenoxy ) phenyl] propane dianhydride dianhydride (BPADA) to the solution, and add 8.411g of titanium dioxide (TiO 2 ) slurry (the solid content of the slurry is about 50%), and the stirring is continued for about 4 hours to form a polyamic acid (PAA) solution.

[0041] The obtained PAA solution was mixed with an acetic anhydride dehydrating agent and a picoline catalyst to obtain a precursor solution. Then, on a glass plate, the precursor so...

Synthetic example 2

[0043] Compared with Synthesis Example 1, the difference of Synthesis Example 2 is that 25.833g of titanium dioxide slurry (solid content of the slurry is about 50%) was added, and the rest of the preparation process was the same as Synthesis Example 1 to form a white polyimide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com