Method for preparing polycarboxylic concrete water reducer with high slump retention capacity, and construction method of polycarboxylic concrete water reducer

A technology of concrete water-reducing agent and polycarboxylic acid, applied in the field of concrete water-reducing agent, can solve the problems of low dosage and single component, and achieve the effects of low dosage, good adaptability and control of slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

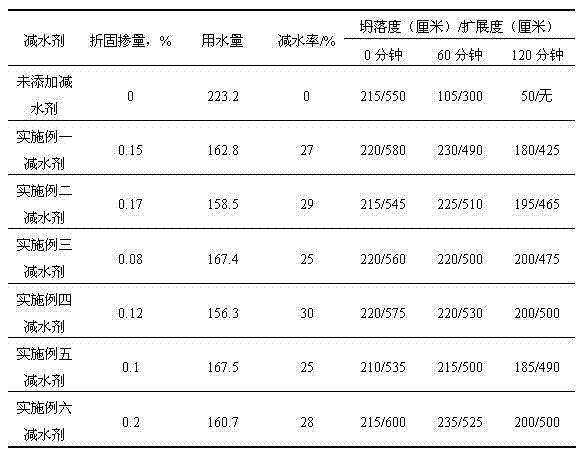

Examples

Embodiment 1

[0023] In a 2-liter four-neck bottle equipped with a thermometer and a dropping funnel, add 1.0 mole-average polyethylene glycol monomethyl ether monomer with a molecular weight of 1200, heat up to 50°C and melt, add 3.45 grams of concentrated sulfuric acid catalyst, and stir for 10 minutes. Then add 0.87 grams of hydroquinone polymerization inhibitor, continue to stir, and then add 2.0 moles of monomeric methacrylic acid after stirring evenly, then raise the temperature of the above-mentioned mixture to 80°C, and react at constant temperature for 4 hours, and remove water through water-carrying agent benzene on the way, that is The oligomer polyethylene glycol monomethyl ether methacrylate was prepared.

[0024] Mix 1 mole of the prepared oligomer polyethylene glycol monomethyl ether methacrylate with 1.5 moles of monomer methacrylic acid, then add 0.31 grams of chain transfer agent thioglycolic acid, 1397 g of 0.01% of the total mass of the reaction system The water is stirr...

Embodiment 2

[0026] In a 2-liter four-necked bottle equipped with a thermometer and a dropping funnel, add 1.0 mole-average polyethylene glycol monomethyl ether monomer with a molecular weight of 1500, heat up to 70°C and melt, add 27.6 grams of 36.5% concentrated hydrochloric acid catalyst, and stir for 30 Minutes later, add 6.89 grams of p-hydroxyanisole polymerization inhibitor, continue to stir, and then add 4 moles of monomeric methacrylic acid after stirring evenly, then raise the temperature of the above mixture to 120°C, and react at constant temperature for 8 hours. Toluene is used to remove water, and the oligomer polyethylene glycol monomethyl ether methacrylate is obtained.

[0027] 1 mole of the prepared oligomer polyethylene glycol monomethyl ether methacrylate is mixed with 6 moles of monomeric acrylic acid, then add 22.08 grams of chain transfer agent mercapto propionic acid accounting for 0.5% of the total mass of the reaction system, add 1600 grams of The water is stirred...

Embodiment 3

[0029]In a 2-liter four-necked bottle equipped with a thermometer and a dropping funnel, add 1.0 mole-average polyethylene glycol monomethyl ether monomer with a molecular weight of 750, heat up to 60°C to melt, add 9.1 grams of p-toluenesulfonic acid catalyst, and stir for 20 minutes Finally, add 2.08 grams of sulfurized diphenylamine polymerization inhibitor, continue to stir, and then add 3.0 moles of monomeric acrylic acid after stirring evenly, then raise the temperature of the above mixture to 100 ° C, and react at constant temperature for 6 hours. The water is removed by distillation, and the oligomer polyethylene glycol monomethyl ether is obtained.

[0030] 1 mole of the prepared oligomer polyethylene glycol monomethyl ether acrylate is mixed with 4 moles of monomer methacrylic acid, and then 6.05 grams of chain transfer agent mercaptoethanol accounting for 0.18% of the total mass of the reaction system is added, and 1568 grams of water are added. Stir evenly to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com