Sugar reducing sour milk

A technology for yogurt and hypoglycemia, which is applied in the direction of milk preparations, dairy products, applications, etc., and can solve problems such as insecurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

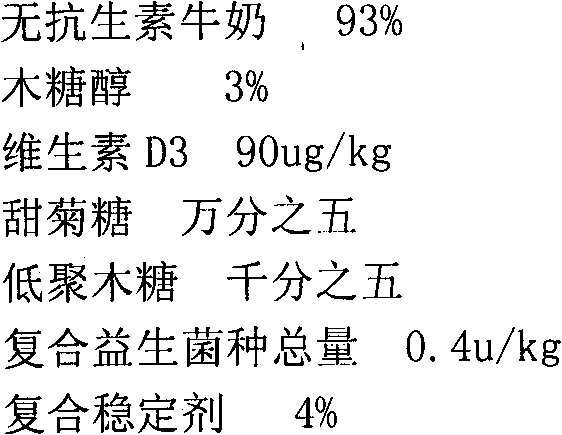

[0020] Embodiment 1 formula (every kilogram of raw material):

[0021]

[0022] Preparation process: Raw milk testing, adjust the standard of fat content ≥ 3.1%, protein ≥ 2.9%, and fat content ≥ 8.3% in fresh milk without antibiotics, and stevioside, xylooligosaccharides, sugar alcohols, and stable The agent is dissolved in milk at 70°C and mixed, homogenized under 20MPa pressure, then sterilized at 95°C for 300 seconds, cooled to 38°C, added with compound bacteria and vitamin D inoculation according to the above ratio, and fermented for 6 hours. When the pH value of the fermented milk reaches 4.2, the fermentation is stopped to obtain the hypoglycemic yogurt of the present invention containing about 42ug / kg of vitamin D.

Embodiment 2

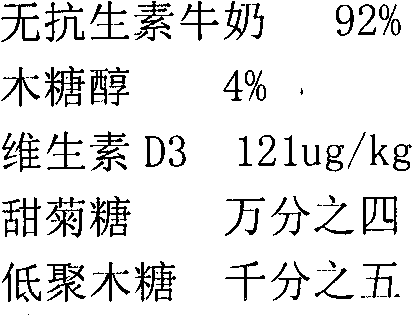

[0023] Embodiment 2 formula (every kilogram of raw material):

[0024]

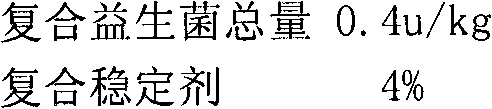

[0025]

[0026] Preparation process: Raw milk testing, adjust the standard of fat content ≥ 3.1%, protein ≥ 2.9%, and fat content ≥ 8.3% in fresh milk without antibiotics, and stevioside, xylitol, xylooligosaccharide, stable The agent is dissolved in milk at 70°C and mixed, homogenized under 20MPa pressure, then sterilized at 95°C for 200 seconds, cooled to 38°C, added with compound bacteria and vitamin D inoculation according to the above ratio, and fermented for 6 hours. When the pH value of the fermented milk reaches 4.2, the fermentation is stopped to obtain the hypoglycemic yogurt of the present invention containing about 60 ug / kg of vitamin D.

Embodiment 3

[0027] Embodiment 3 formula (every kilogram of raw material)

[0028]

[0029] Preparation process: Raw milk testing, adjust the standard of fat content ≥ 3.1%, protein ≥ 2.9%, and fat content ≥ 8.3% in fresh milk without antibiotics, and stevioside, xylooligosaccharides, xylitol, and stable The agent is dissolved in milk at 70°C and mixed, homogenized under 20MPa pressure, then sterilized at 95°C for 300 seconds, cooled to 38°C, added with compound bacteria and vitamin D inoculation according to the above ratio, and fermented for 6 hours. When the pH value of the fermented milk reaches 4.2, the fermentation is terminated to obtain the hypoglycemic yogurt of the present invention containing about 95 ug / kg of vitamin D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com