Patch support for water-based plaster

一种支撑体、膏体的技术,应用在水性膏体用贴附支撑体领域,能够解决膏体保持性及保水性药效持续性存在问题等问题,达到膏体保持性及保水性优异、追随性优异、降低压迫束缚感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

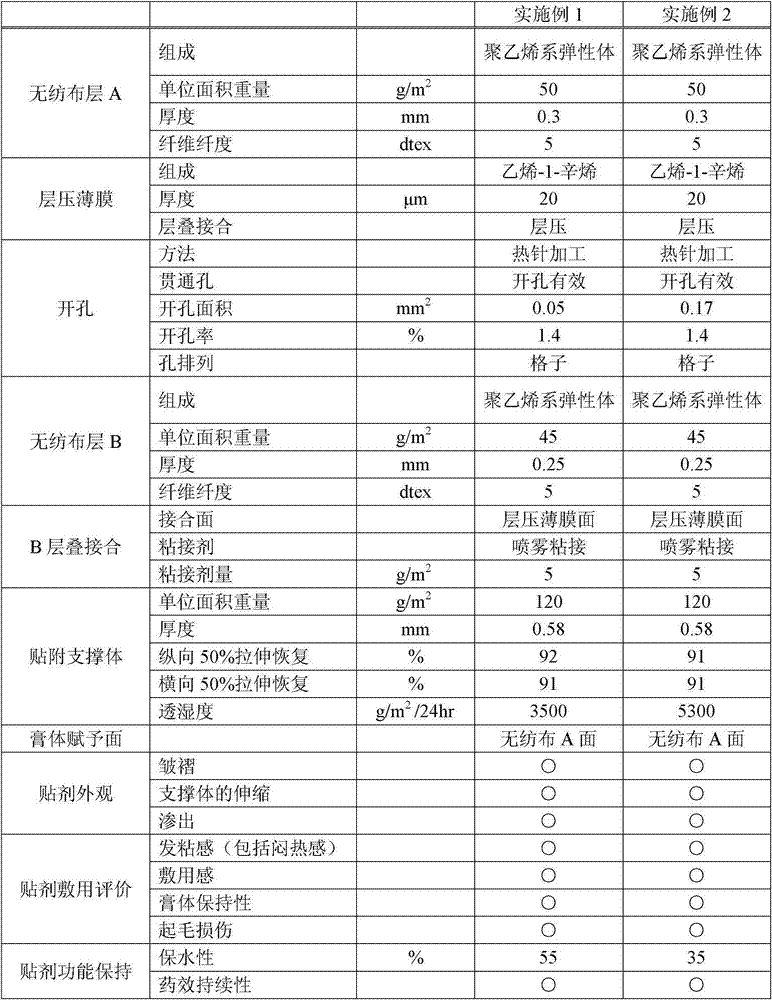

[0099] As the non-woven fabric layer A, Idemitsu Unitech Co., Ltd. made UN5050 (spun-bonded non-woven fabric using olefin-based elastomer resin, weight per unit area: 50 g / m 2 , thickness 0.3mm, fineness 5dtex) is laminated with a film with a thickness of 20 μm of MORETEC 0218CN (ethylene-1-octene copolymer) manufactured by Prime Polymer Co., Ltd. Needle processing to give each through hole an area of 0.05mm 2 , through holes with a porosity of 1.4% to maintain the shape of the hole, and then, as the non-woven fabric layer B, UN5040R (spun-bonded non-woven fabric using olefin-based elastomer resin, unit area Weight 45g / m 2 , thickness 0.25mm), on the elastomer film surface of the non-woven fabric layer A / elastomer film laminate processed through the through hole, use the spray method according to 5g / m 2 Adhesive is supplied, and nonwoven fabric B is laminated and bonded by a conventional method to obtain a weight per unit area of 105 g / m 2 , thickness 0.4mm, 50% tensile...

Embodiment 2

[0103] The area of each through-hole of the elastomer film of Example 1 was set to 0.17mm 2 , The same support as in Example 1 was obtained except that the porosity was set to 1.4%. The resulting support has a weight per unit area of 105 g / m 2 , thickness 0.4mm, 50% tensile recovery rate 91%, moisture permeability 5300g / m 2 • 24-hour support.

[0104] Table 1 shows the performance of the obtained support and the evaluation results when it was made into a patch.

[0105] The patch using the support of Example 2 has excellent elasticity and plaster retention, has a good application feeling without sticky feeling, is also excellent in water retention, and suppresses the sublimation of the drug to improve the durability of the drug effect Patches for water-based ointments.

Embodiment 3

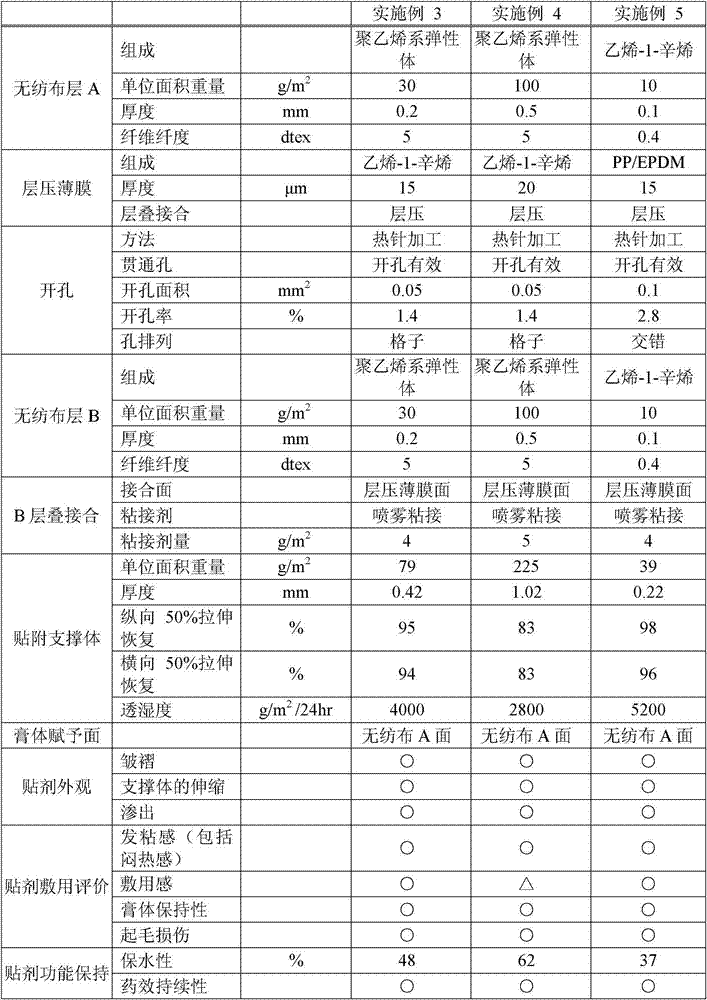

[0107] U-shaped 30 g / m made by Idemitsu Unitech Co., Ltd. as the non-woven fabric layer A 2 (Spun-bonded non-woven fabric using olefin-based elastomer resin, basis weight 30g / m 2 , thickness 0.2mm, fineness 5dtex) is laminated with a 15μm film of MORETEC 0218CN (ethylene-1-octene copolymer) manufactured by Prime Polymer Co., Ltd., and hot needle processing is performed from the elastomer film side with a needle diameter 0.7mm , thus giving each through-hole an area of 0.05mm 2 , A through-hole with an opening ratio of 1.4% to maintain the shape of the hole, and then, as the non-woven fabric layer B, U-shaped 30g / m made by Idemitsu Unitech Co., Ltd. 2 (Spun-bonded non-woven fabric using olefin-based elastomer resin, basis weight 30g / m 2 , thickness 0.2mm), on the elastomer film surface of the non-woven fabric layer A / elastomer film laminate processed through the through hole, spray at 4g / m 2 An adhesive is supplied, and the nonwoven fabric layer B is stacked and bonded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com