Light emitting diode (LED) drive circuit controlled by parallel connection high voltage metal oxide semiconductor (MOS) tube

A technology of LED drive and MOS tube, which is applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve the problems of service life impact, unsatisfactory power factor, low cost, etc., and achieve reduction in volume and cost, and circuit conversion efficiency High, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawings and embodiments thereof.

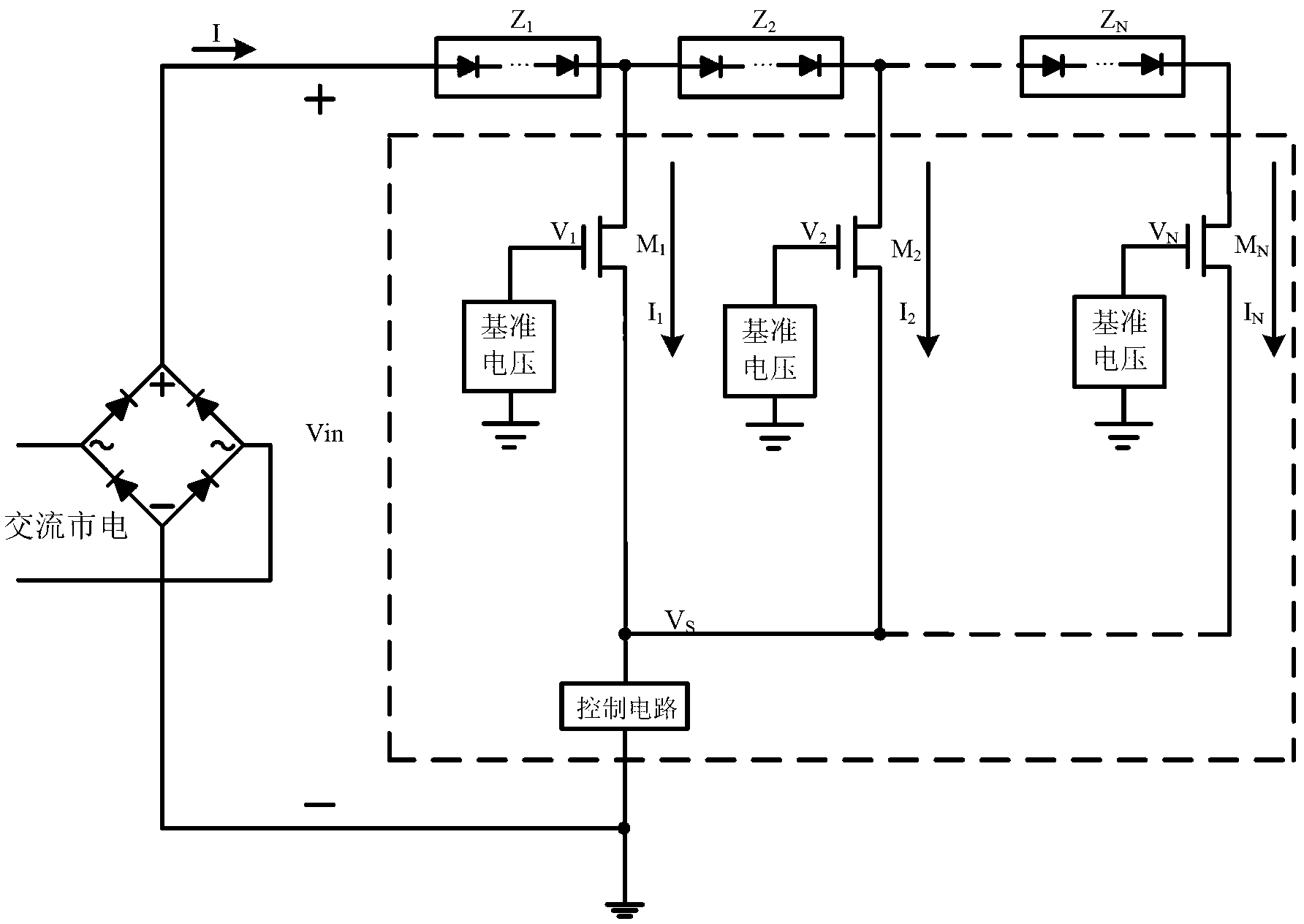

[0031] refer to image 3 , LED driver circuit of the present invention comprises: rectifier bridge, control circuit N series load Z 1 ~ Z N , N high-voltage MOS tubes M 1 ~ M N and N voltage reference circuits, N≥1; where:

[0032] A rectifier bridge for full-wave rectification of AC signals;

[0033] N series load Z 1 ~ Z N , a single group connected in series to form a variable load network, and connected across the rectifier bridge and the Nth high-voltage MOS tube M N Each string of loads is composed of L light-emitting diodes LEDs connected in series, L×N<100;

[0034] N high voltage MOS tubes M 1 ~ M N , used to control the load size of the access circuit; the source of each high-voltage MOS tube is connected to the control circuit; the gate of each high-voltage MOS tube is connected to N voltage references; the first high-voltage MO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com