Carbon nano tube cement based composite sensor testing system

A sensor subsystem and composite material technology, applied in the field of engineering structure sensor test system, can solve the problems of increasing the number of sensors, increasing the complexity of the data volume system, affecting the reliability and flexibility of the system, and increasing the load of the monitoring object, etc. Effects of destruction, improved transmission distance, and reduced measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail with reference to the accompanying drawings.

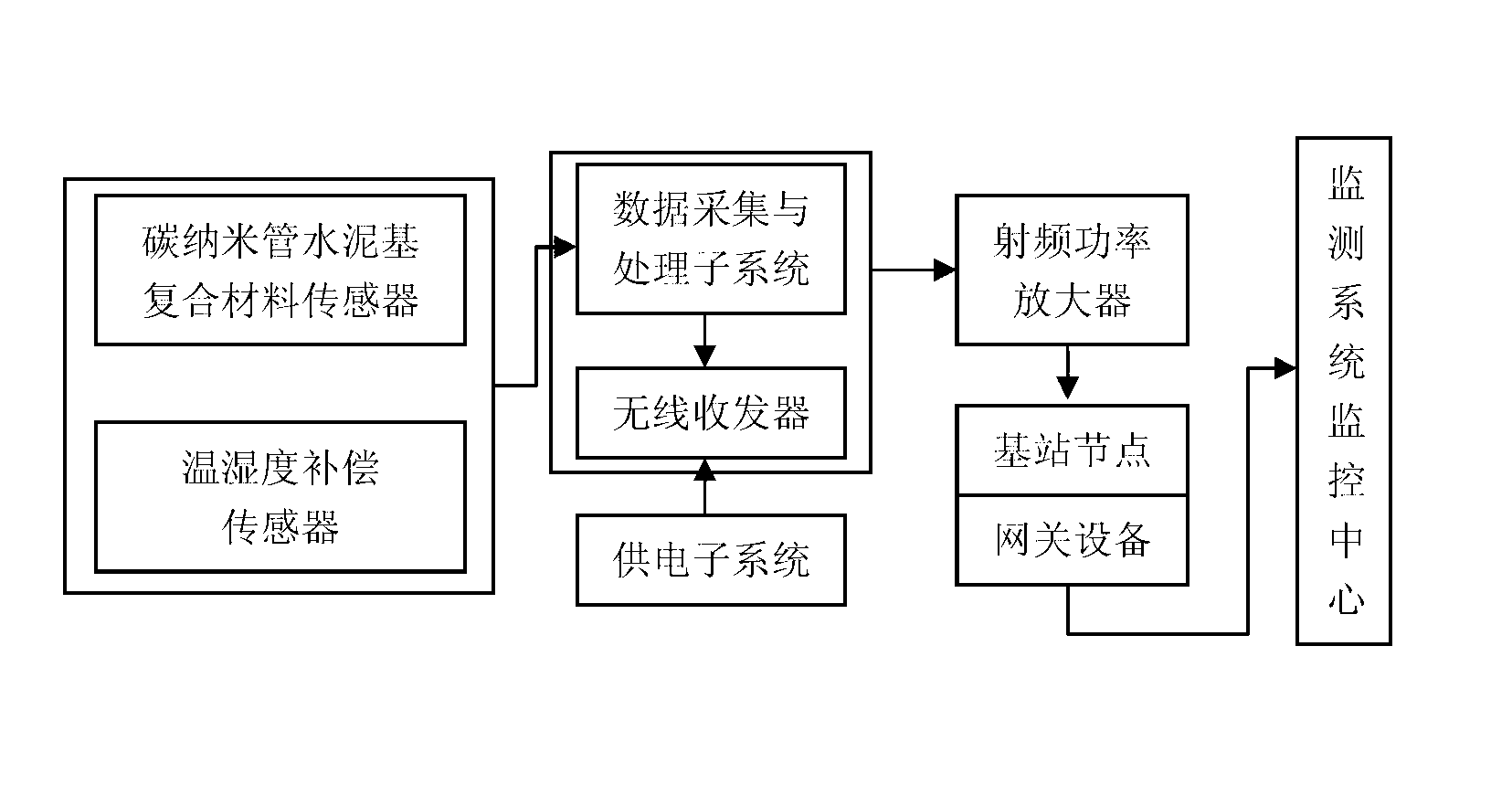

[0016] Embed a 30mm×30mm×120mm carbon nanotube cement-based composite sensor and a temperature and humidity compensation sensor at the node to be tested. Establish data acquisition processing and communication subsystems, perform A / D conversion, digital filtering and denoising operations on received digital signals and data, and transmit data wirelessly through the support of power supply subsystems and RF power amplifiers. The base station node receives and processes the data information, and the connected gateway device converts the wireless sensor network protocol into an IP network protocol, and sends the data to the monitoring center through the Internet to establish a wireless sensor network-based engineering structure health monitoring system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com