Compounding and coating method of anode material for lithium ion cell

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of positive electrode material structure decomposition and cycle performance deterioration, and achieve improved stability, cycle performance and rate discharge performance. The effect of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

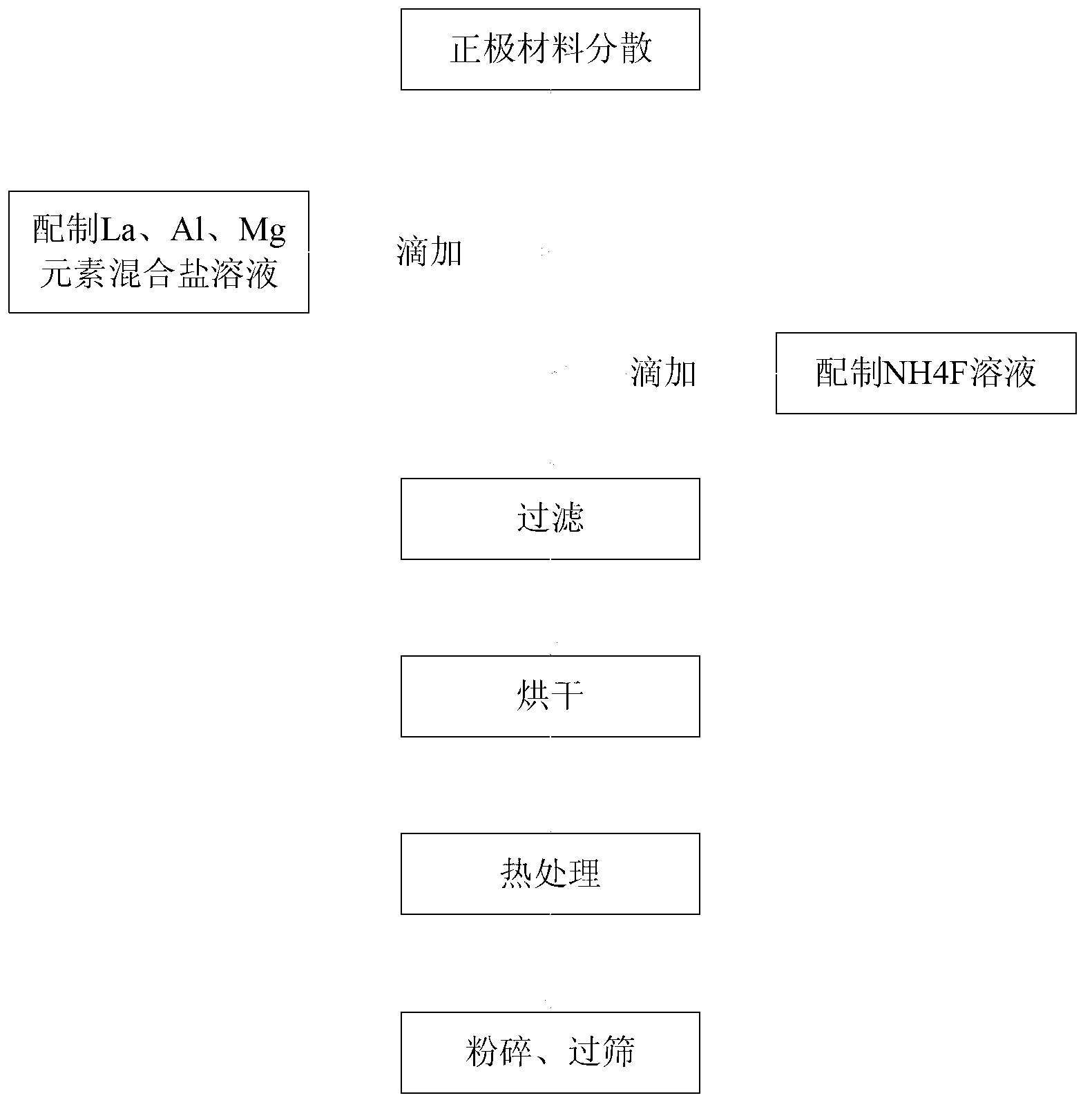

Method used

Image

Examples

Embodiment 1

[0030] Prepare 570ml of mixed solution of lanthanum nitrate, aluminum nitrate and magnesium nitrate according to the molar ratio of elements La:Al:Mg=1:1:1, La 3+ 、Al 3+ , Mg 2+ The total concentration of 0.5mol / L; the preparation concentration of 1mol / L NH 4 F solution.

[0031] Put 3000g of lithium cobalt oxide cathode material into 5000ml of deionized water, stir with an electric stirrer, and keep the solution temperature at 20°C. During the stirring process, 570ml of the nitrate solution was added dropwise into the lithium cobalt oxide material slurry, and the stirring was continued for 0.5h after the dropwise addition was completed.

[0032] Add NH dropwise 4 F solution. Use a precision pH meter to measure the pH value of the solution, and stop adding NH when the pH value reaches 8-9 4 F solution, continue to stir for 0.5h.

[0033] The slurry was filtered, and the filtrate was dried at 100° C. for 10 h. The dried powder was heat-treated at 600 °C for 10 h in a mu...

Embodiment 2

[0036] Prepare 1100ml of mixed solution of lanthanum nitrate, aluminum nitrate and magnesium nitrate according to the molar ratio of La:Al:Mg=0.5:1:0.5, the total concentration of La, Al and Mg is 1mol / L; the preparation concentration is 2mol / L of NH 4 F solution.

[0037] Put 5000g of lithium cobalt oxide cathode material into 15000ml of deionized water, keep the temperature of the solution at 60°C, and stir with an electric stirrer. During the stirring process, 1100 ml of the nitrate solution was added dropwise into the lithium cobalt oxide material slurry, and the stirring was continued for 0.5 h after the dropwise addition was completed.

[0038] Add NH dropwise 4 F solution. Use a precision pH meter to measure the pH value of the solution, and stop adding NH when the pH value reaches 8-9 4 F solution, continue to stir for 0.5h.

[0039] The slurry was filtered, and the filter was dried at 110° C. for 10 h. The powder obtained after drying was put into a muffle furnac...

Embodiment 3

[0042]Prepare 2400ml of mixed solution of lanthanum nitrate, aluminum nitrate and magnesium nitrate according to the molar ratio of La:Al:Mg=2:1:1, the total concentration of La, Al and Mg is 2.5mol / L; the prepared concentration is 2.5mol / L NH 4 F solution.

[0043] 20kg LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material was put into 40L deionized water, and the temperature of the solution was kept at 30°C, and stirred with an electric stirrer. Add 2400ml of nitrate solution dropwise to LiNi during stirring 1 / 3 co 1 / 3 mn 1 / 3 o 2 In the material slurry, the stirring was continued for 1 h after the dropwise addition was completed.

[0044] Add NH dropwise 4 F solution. Use a precision pH meter to measure the pH value of the solution, and stop adding NH when the pH value reaches 8-9 4 F solution, continue to stir for 1h.

[0045] The slurry was filtered, and the filter was dried at 150° C. for 10 h. The powder obtained after drying was put into a muffle furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com