Amorphous carbon processing method and etching method by adopting amorphous carbon as hard mask

A technology of amorphous carbon and processing methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high process requirements for hard mask layer and limited range of boron doping dose, etc., and achieve precise etching process, Unlimited effect of boron doping dose range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

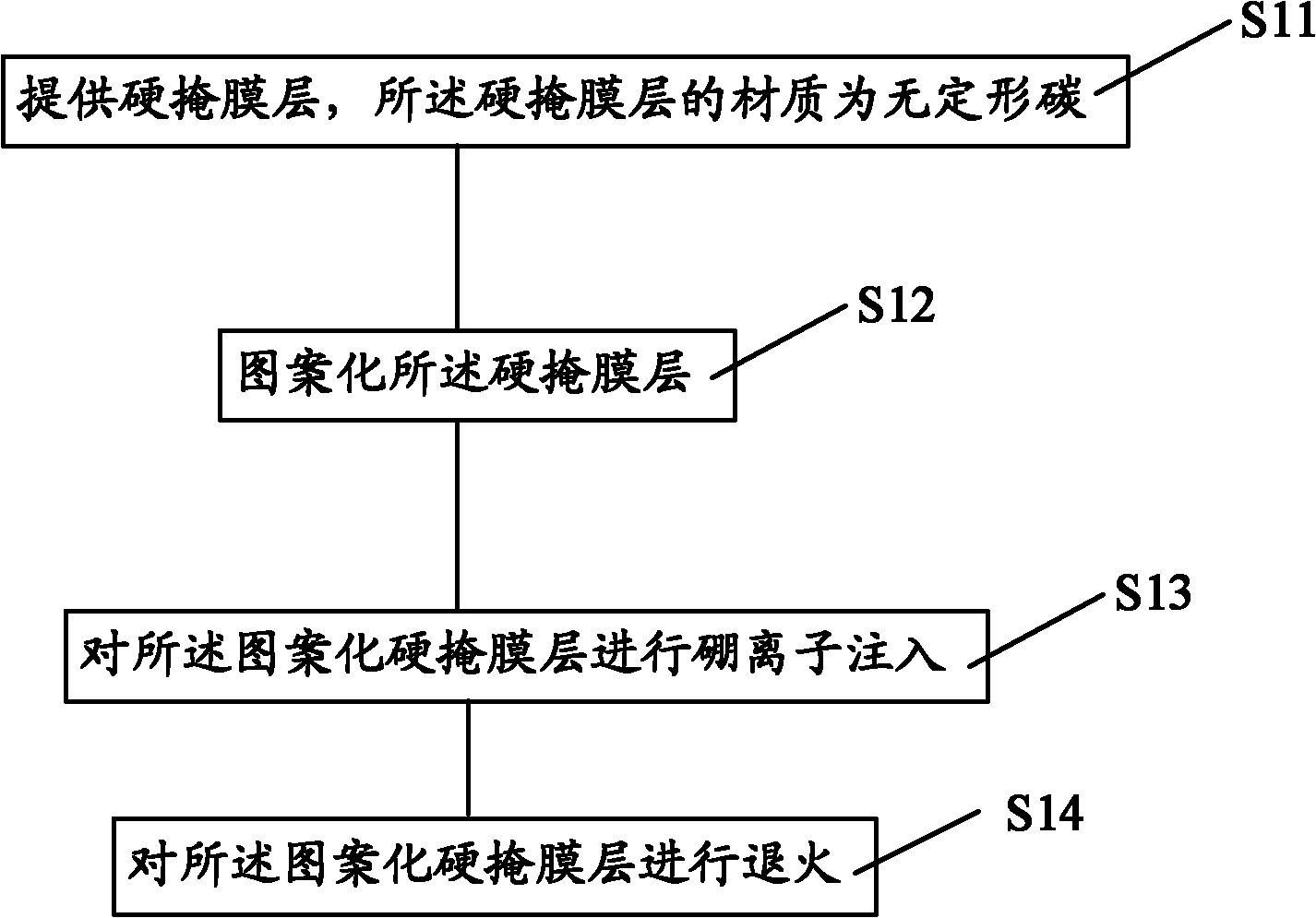

[0055]In the present invention, the pattern on the mask plate is first aligned with the pattern of the amorphous carbon detection alignment mark and the substrate, and then the hard mask layer is patterned; The improvement of the light transmittance becomes worse, which affects the alignment accuracy; after that, boron ion implantation is performed on the patterned hard mask layer to form a new patterned hard mask layer, and the new patterned hard mask layer As a mask, the layer to be etched is etched, so that the entire etching process is precise and the boron dosage range is not limited.

[0056] In addition, the boron ion implantation is carried out after the hard mask layer has been patterned, in other words, only boron ions are contained on the surface of the amorphous carbon. Since the hard mask layer is mainly used for the surface layer during the etching process, Therefore, it acts as a hard mask, and when the hard mask is removed later, the surface area only needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com