Graphene-carbon nano composite transparent conducting thin film and preparation method thereof

A technology of transparent conductive film and composite film, applied in the direction of graphene, nano-carbon, nanotechnology, etc., can solve the problems of low degree of graphitization, poor flatness, limited performance of graphene film, etc., and achieve simple process and mild properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a graphene-carbon nanocomposite transparent conductive film, which is characterized in that the method comprises preparing a mixed dispersion liquid containing graphite oxide and a carbon-forming precursor, making the mixed dispersion liquid form a film on a substrate, and preparing Obtain graphene oxide-carbon-forming precursor composite film, then under the conditions that graphene oxide is reduced and carbon-forming precursor is carbonized, the graphene oxide-carbon-forming precursor composite film is subjected to heat treatment, and the graphite oxide The weight ratio of carbon-forming precursor and carbon-forming precursor is 1: (0.04-5).

[0020] According to the present invention, the weight ratio of the graphite oxide to the carbon-forming precursor can be selected within a wide range, preferably, the weight ratio of the graphite oxide to the carbon-forming precursor is 1:(0.4-3.5). When the weight ratio of the carbo...

preparation example 1

[0039] Mix graphite flakes (1 part by mass) and sodium nitrate (1 part by mass), ice bath for 2 hours, add potassium permanganate (4 parts by mass), raise the temperature to about 35°C, keep it for 2 hours, then raise the temperature to 75°C, Add 45 parts by mass of water, and after reacting for 15 minutes, add 30% by weight hydrogen peroxide (until no bubbles emerge) and 26.5 parts by mass of water to obtain a bright yellow suspension. The suspension was filtered, the filter cake was washed three times with 3% by weight hydrochloric acid, the obtained filter cake was dried at a temperature of 60° C., and ground into powder to obtain graphite oxide (GO).

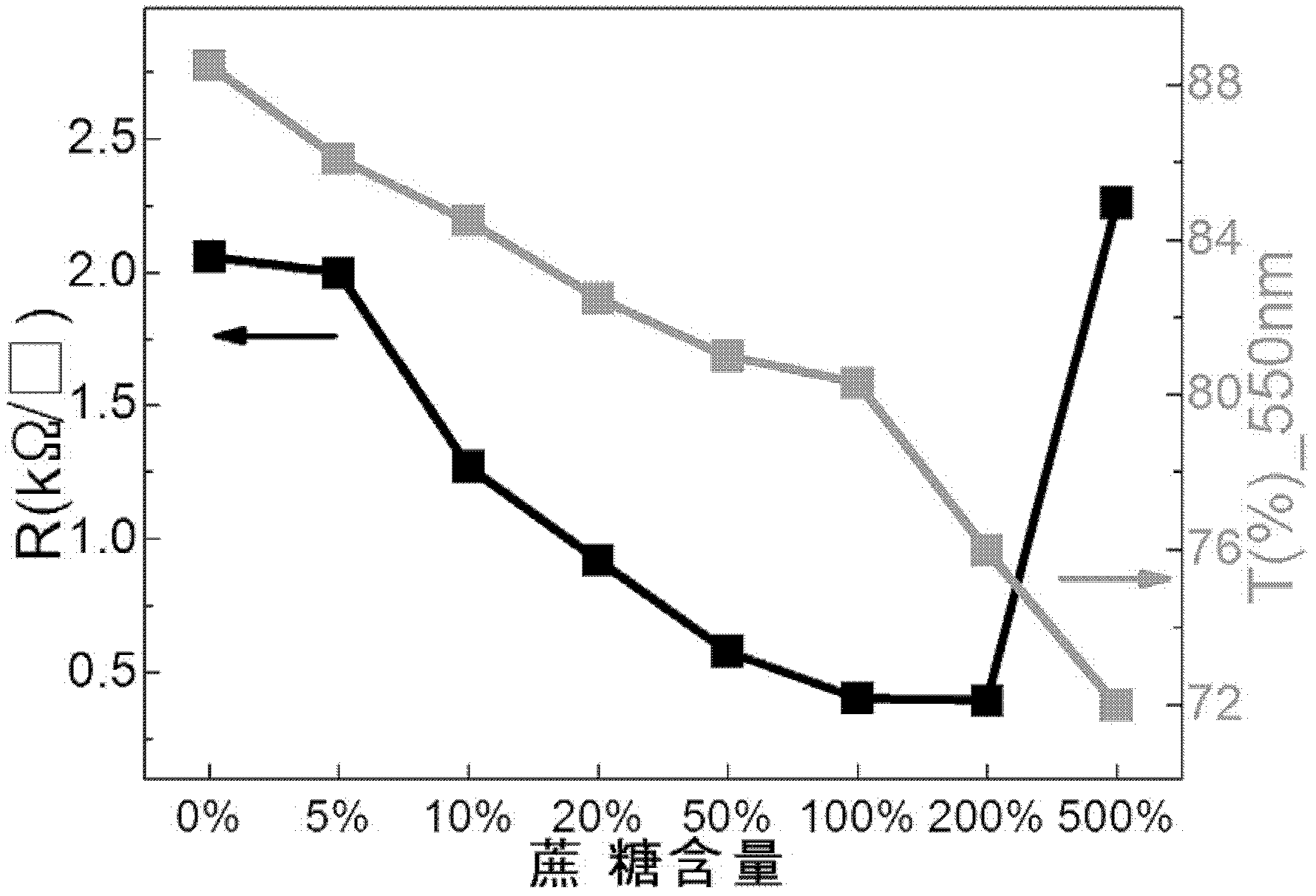

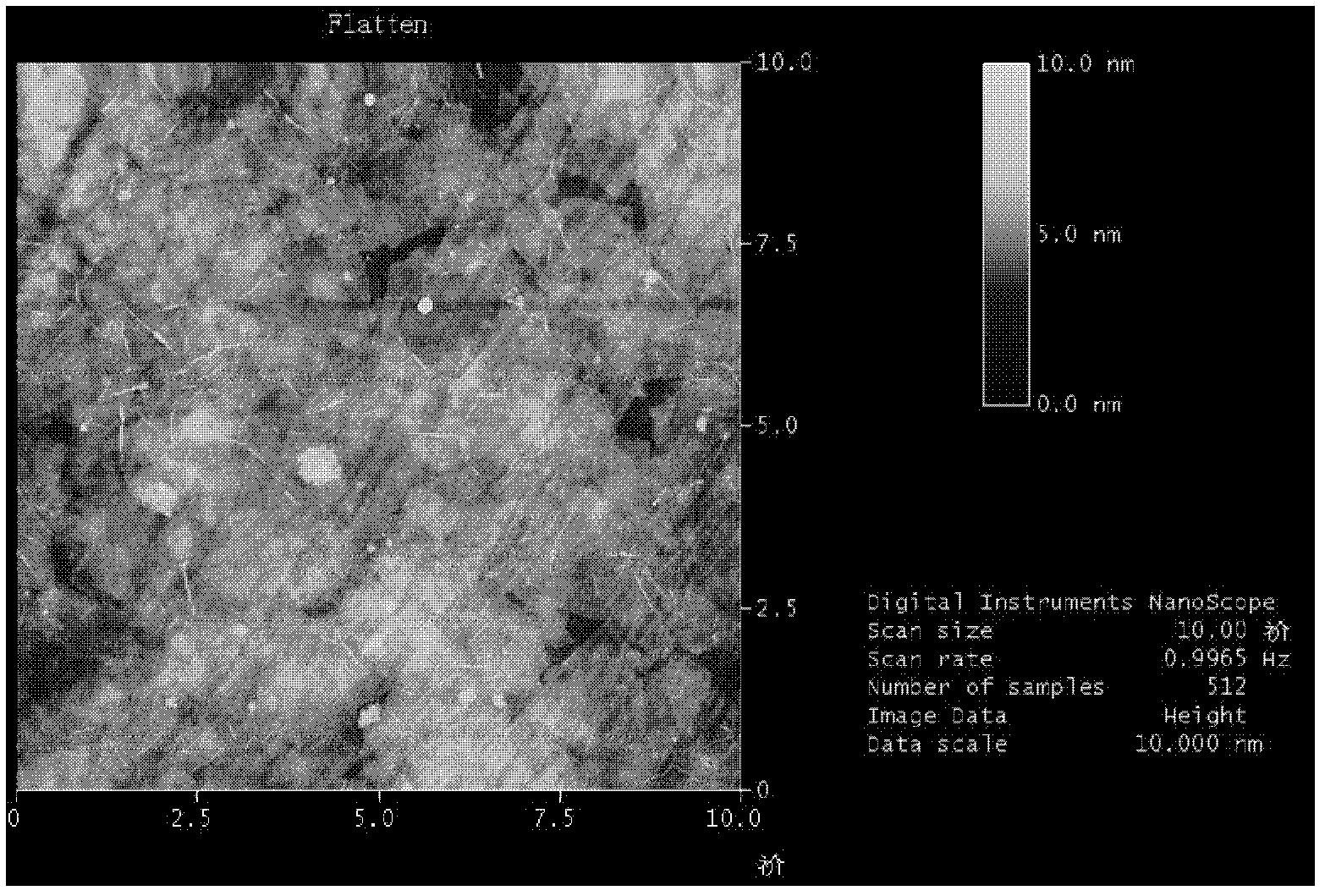

[0040] Then 0.005 grams of graphite oxide and different proportions of sucrose (0%, 5%, 10%, 20%, 50%, 100%, 200%, 500% relative to the mass of GO) were dispersed in 5 grams of THF, ultrasonic ( 150W water bath) for 1 hour to obtain a graphene oxide-sucrose dispersion. By dip-coating (Dip-coating) film-making method, the gr...

preparation example 2

[0045] Mix graphite flakes (1 part by mass) and sodium nitrate (2 parts by mass), ice-bath for 10 hours, add potassium permanganate (6 parts by mass), raise the temperature to about 35°C, keep it for 72 hours, then raise the temperature to 95°C, 45 parts by mass of water were added, and after 15 minutes of reaction, 30% by weight hydrogen peroxide (until no bubbles emerged) and 26.5 parts of water were sequentially added to obtain a bright yellow suspension. The suspension was filtered, the filter cake was washed three times with 3% by weight hydrochloric acid, the obtained filter cake was dried at a temperature of 60° C., and ground into powder to obtain graphite oxide (GO).

[0046] Then 0.005 g of graphite oxide and furfural resin (molecular weight is about 1000) (100% relative to GO mass) were dispersed in 1.25 g of methanol and shaken for 72 hours to obtain graphene oxide-furfural resin dispersion. By the film-making method of film pulling, the graphene oxide-furfural res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com