Parallel-plate multi-electrode capacitance type oil level sensor

An oil level sensor and multi-electrode technology, which is applied in the field of sensors, can solve problems affecting measurement accuracy, deposited impurities, and influences, and achieve the effects of reducing measurement errors, reducing complexity, and facilitating production debugging and on-site testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

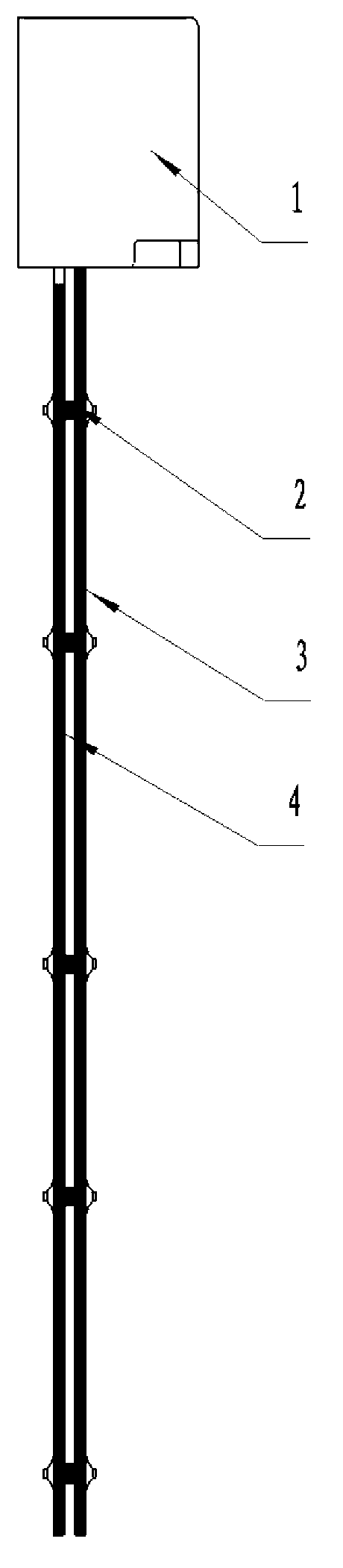

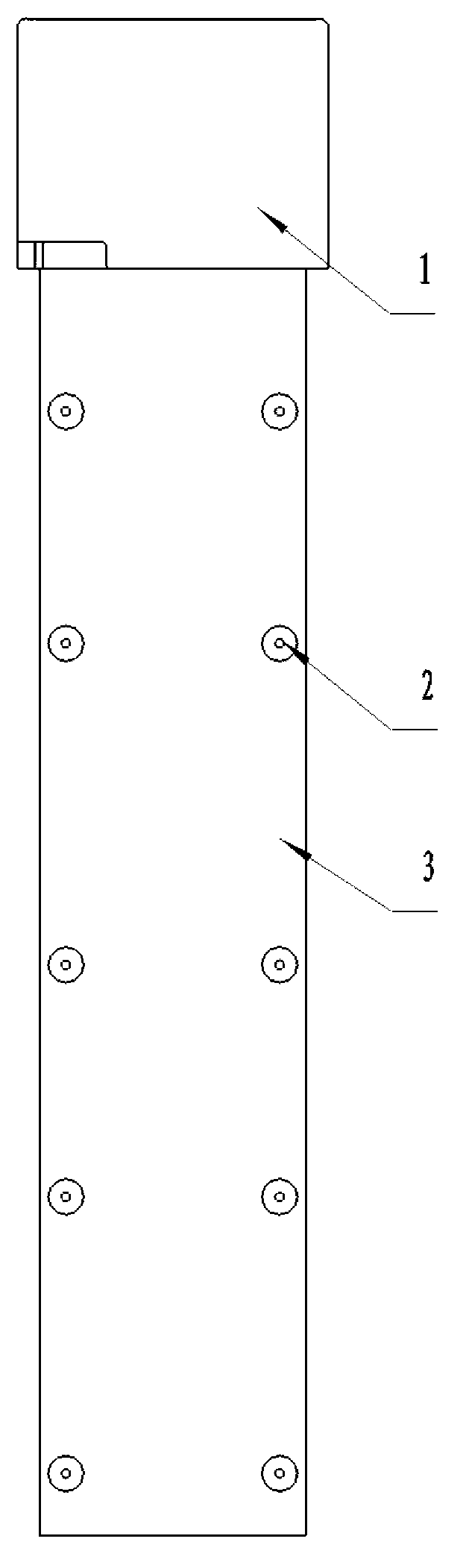

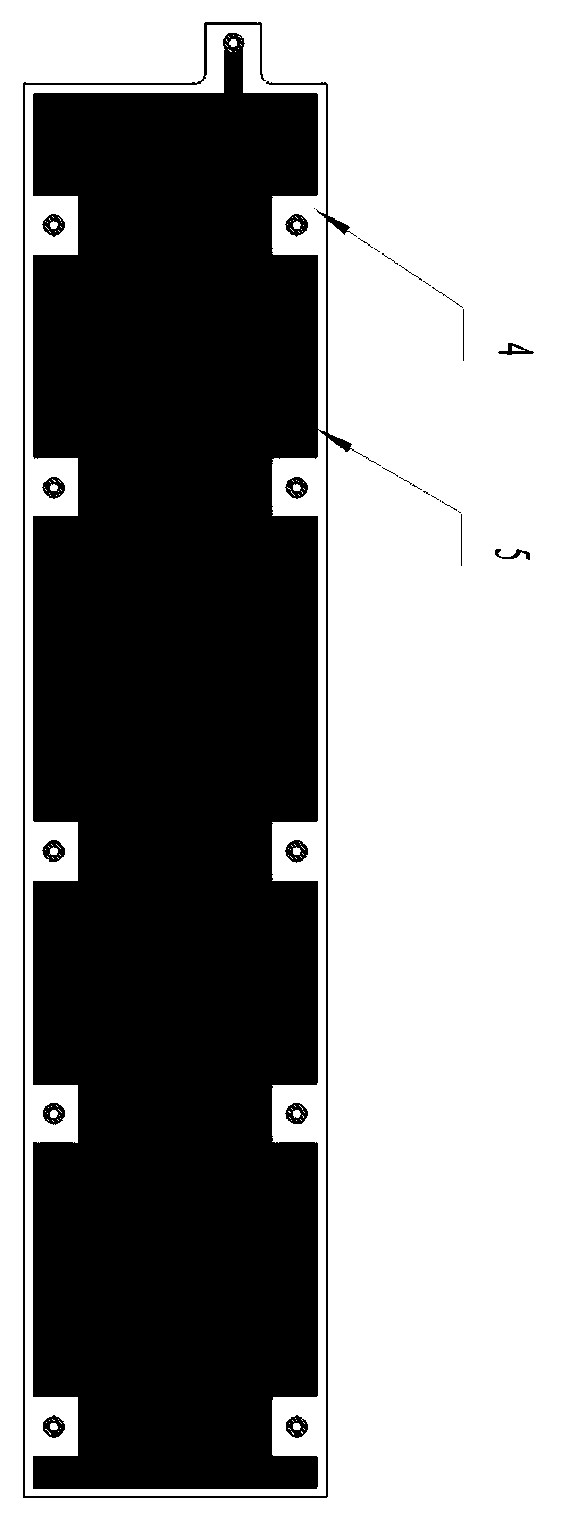

[0026] Embodiment one: see figure 1 , figure 2 , image 3 and Figure 4 , a parallel plate multi-electrode capacitive oil level sensor, comprising a multi-electrode plate 3, a common electrode plate 4 corresponding to the middle and lower parts of the multi-electrode plate, the common electrode plate is connected to the multi-electrode plate through a plurality of fixing columns 2 plate 3 and parallel to it, the distance between the multi-electrode plate and the common electrode plate is 1 mm; the upper part of the multi-electrode plate 3 and the upper end of the common electrode plate 4 are inserted into the protective box 1 together, and epoxy resin It is sealed to isolate the data acquisition and data processing circuit and signal output circuit from the oil to avoid contamination and damage.

[0027] The upper part of the multi-electrode plate 3 is provided with a control circuit 6, which includes a power supply circuit, a data acquisition and processing circuit and a ...

Embodiment 2

[0030] Embodiment two: see figure 1 , figure 2 , image 3 and Figure 4 , a parallel plate multi-electrode capacitive oil level sensor, comprising a multi-electrode plate 3, a common electrode plate 4 corresponding to the middle and lower parts of the multi-electrode plate, the common electrode plate is connected to the multi-electrode plate through a plurality of fixing columns 2 plate 3 and parallel to it, the distance between the multi-electrode plate and the common electrode plate is 1.3 mm; the upper part of the multi-electrode plate 3 and the upper end of the common electrode plate 4 are inserted into the protective box 1 together, and covered with epoxy The resin is sealed to isolate the data acquisition and data processing circuit and the signal output circuit from the oil to avoid contamination and damage.

[0031] The upper part of the multi-electrode plate 3 is provided with a control circuit 6, which includes a power supply circuit, a data acquisition and proce...

Embodiment 3

[0034] Embodiment three: see figure 1 , figure 2 , image 3 and Figure 4, a parallel plate multi-electrode capacitive oil level sensor, comprising a multi-electrode plate 3, a common electrode plate 4 corresponding to the middle and lower parts of the multi-electrode plate, the common electrode plate is connected to the multi-electrode plate through a plurality of fixing columns 2 plate 3 and parallel to it, the distance between the multi-electrode plate and the common electrode plate is 1.5mm; the upper part of the multi-electrode plate 3 and the upper end of the common electrode plate 4 are inserted into the protective box 1 together, and covered with epoxy The resin is sealed to isolate the data acquisition and data processing circuit and the signal output circuit from the oil to avoid contamination and damage.

[0035] The upper part of the multi-electrode plate 3 is provided with a control circuit 6, which includes a power supply circuit, a data acquisition and proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com