Phase-change heat transfer type intermediate temperature heat reservoir as well as manufacturing and application thereof

A technology of phase-change heat and heat storage, applied in the direction of indirect heat exchangers, heat exchanger types, applications, etc., can solve the problems of low heat collection temperature of heat collectors, no heat storage, etc., and achieve heat exchange area Large, random installation, high heat transfer coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solutions of the present invention, but the protection scope of the present invention is not limited to the following implementations example.

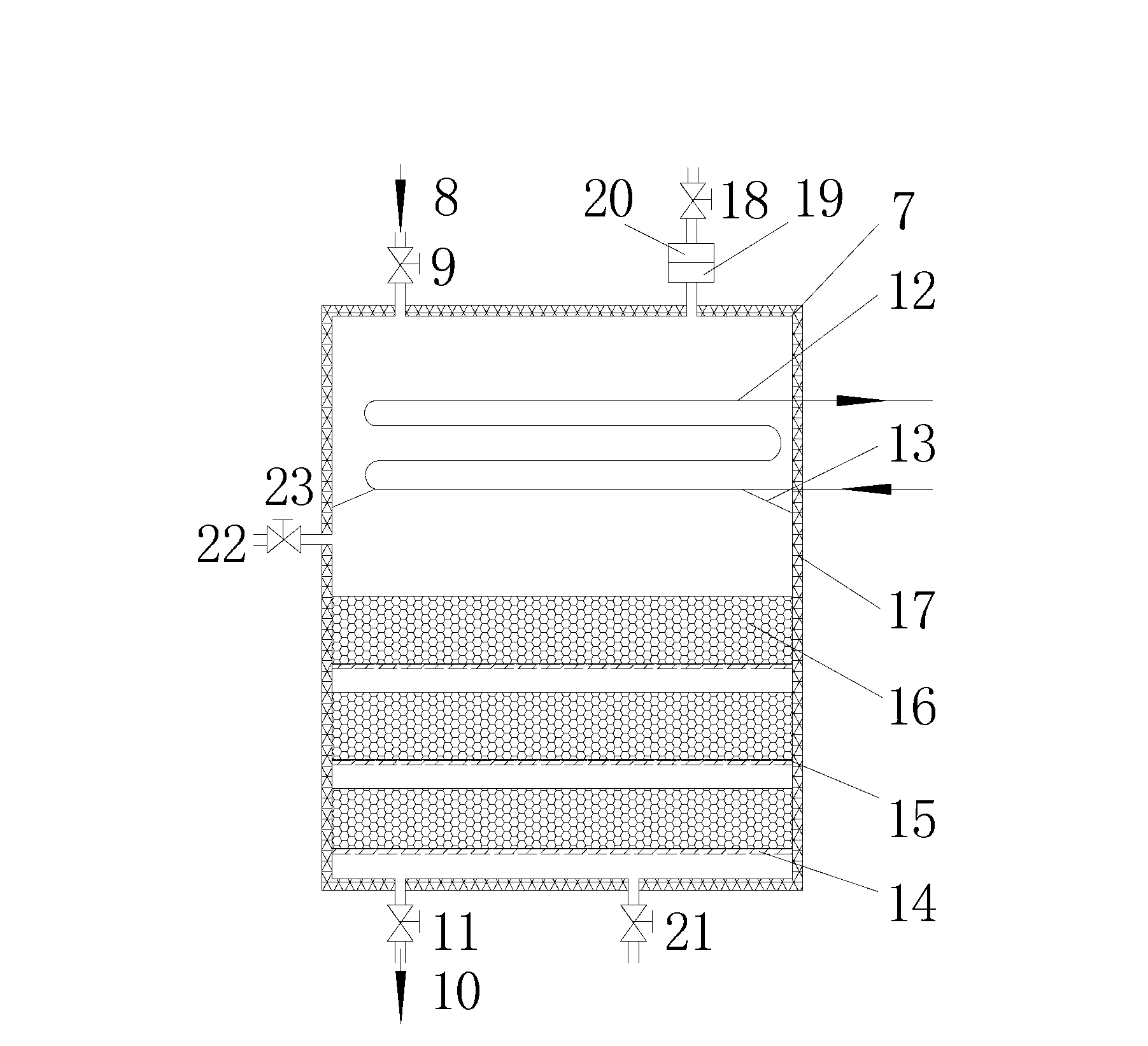

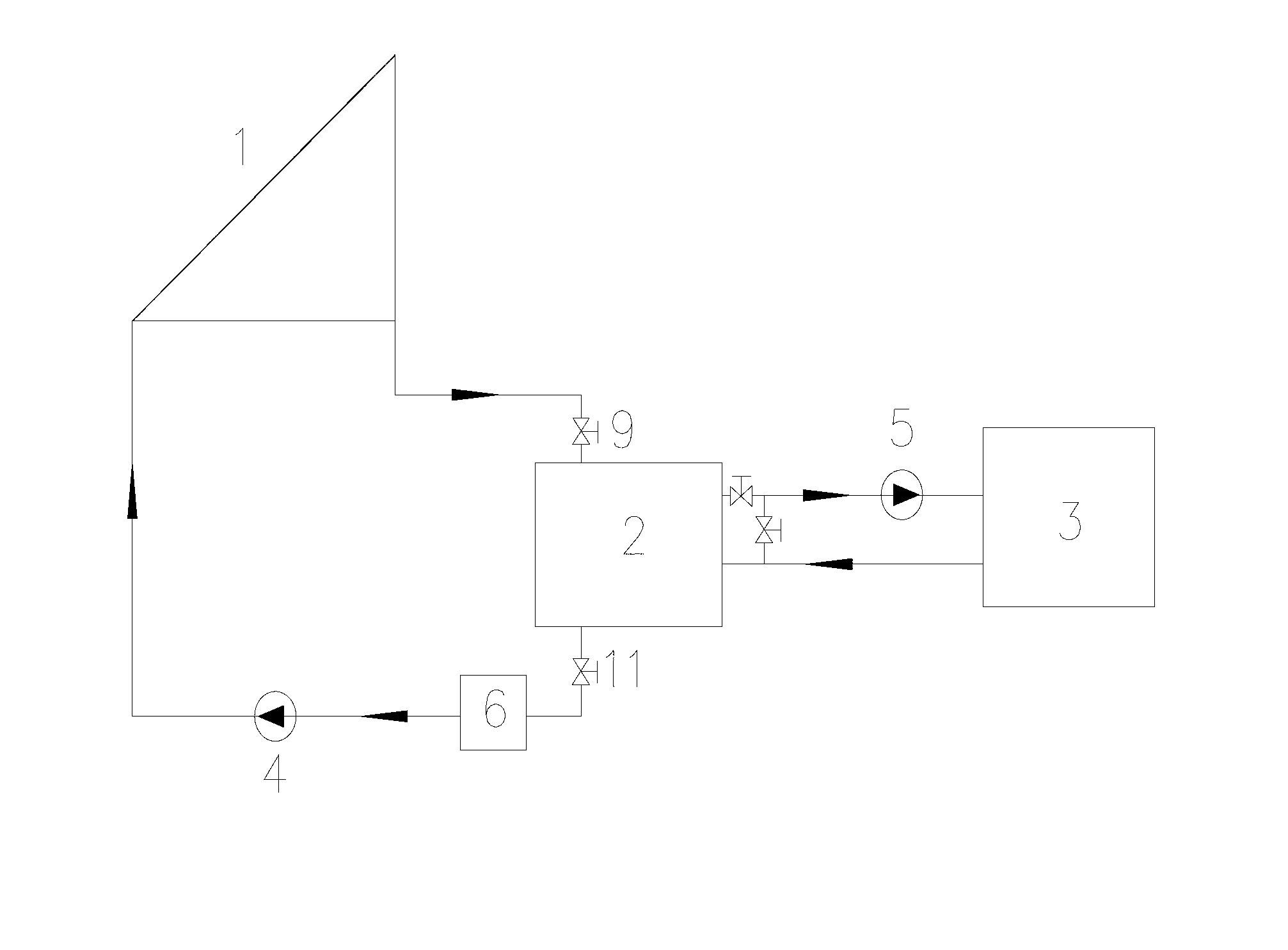

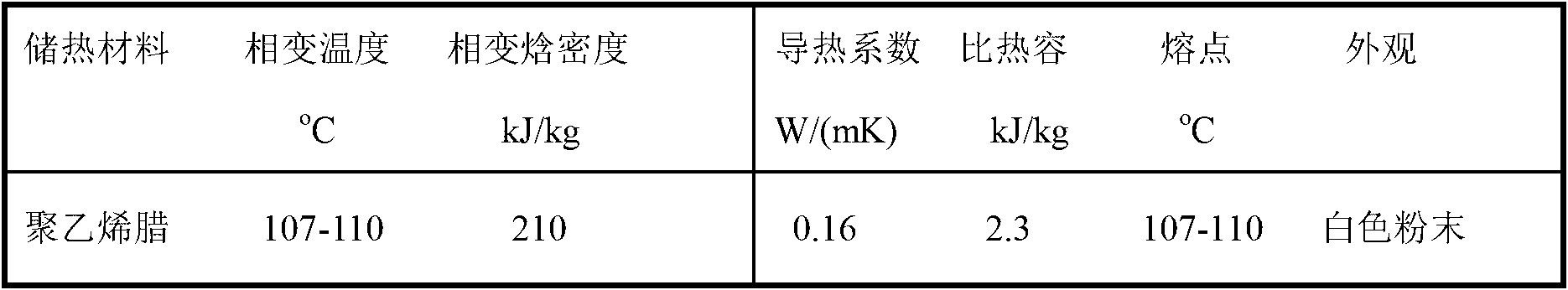

[0031] see figure 1 , as shown in the figure, the phase-change heat storage medium-temperature heat storage device 2 is a closed pressure-resistant container made of stainless steel, including a box body 7, a plurality of hoops 14, a screen 15, a heat storage accumulation layer 16 and a heat exchange tube 12.

[0032] In the present embodiment, the box body 7 is a stainless steel cylindrical container with a diameter of 1.2m, a total height of 1.5m, and a wall thickness of 3mm, and its outer periphery is wrapped with an insulating material 17; The water vapor valve 9 and the water vapor inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com