Light-emitting diode (LED) tunnel lamp

A technology of LED tunnel lights and LED lamp caps, applied in the cooling/heating devices of lighting devices, outdoor lighting, lighting and heating equipment, etc., can solve the problems of poor lighting effect, unsatisfactory lighting effect, heavy weight, etc. Progress and economic and social benefits, achieving the effect of no power dissipation, enhanced light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

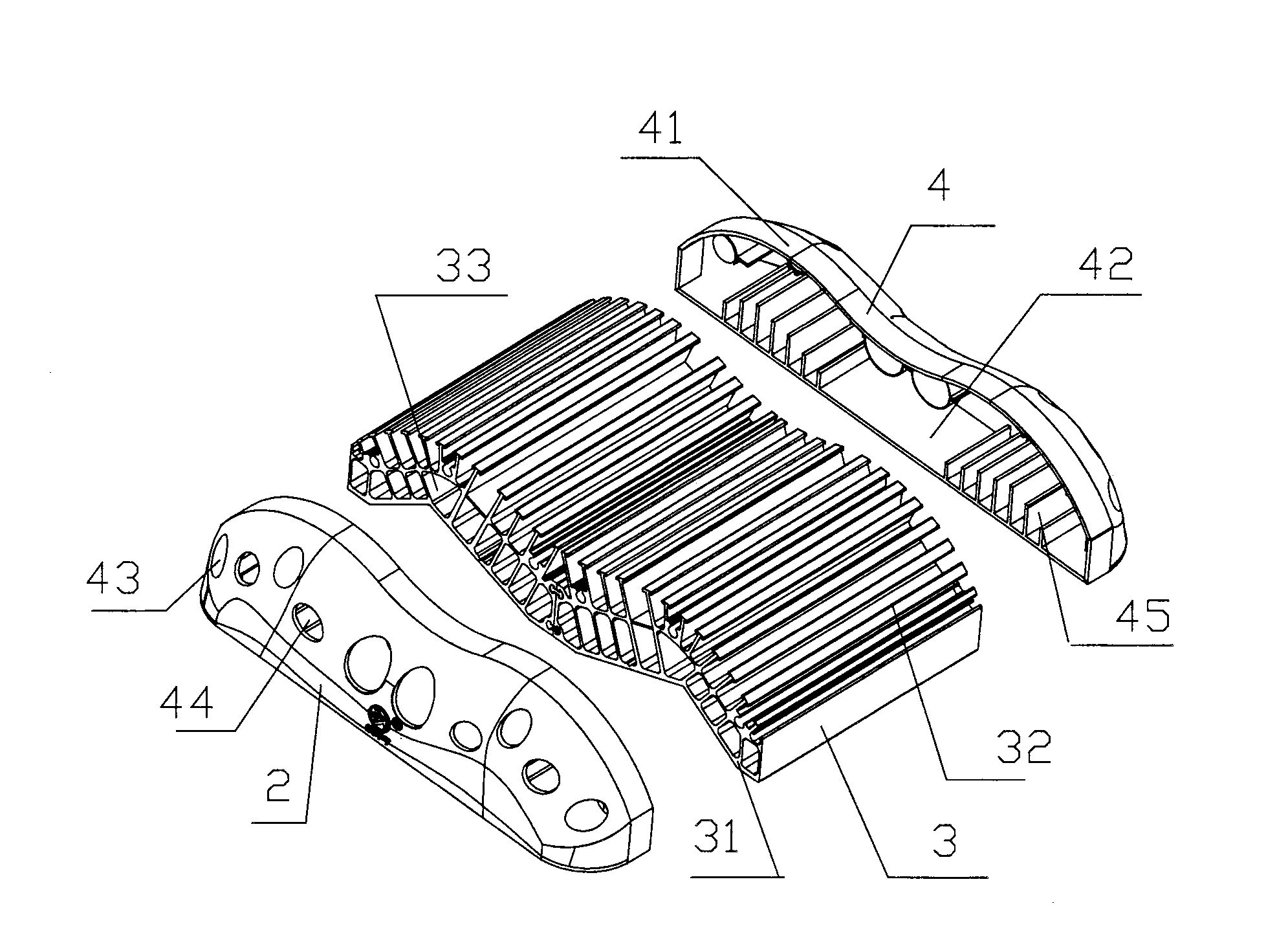

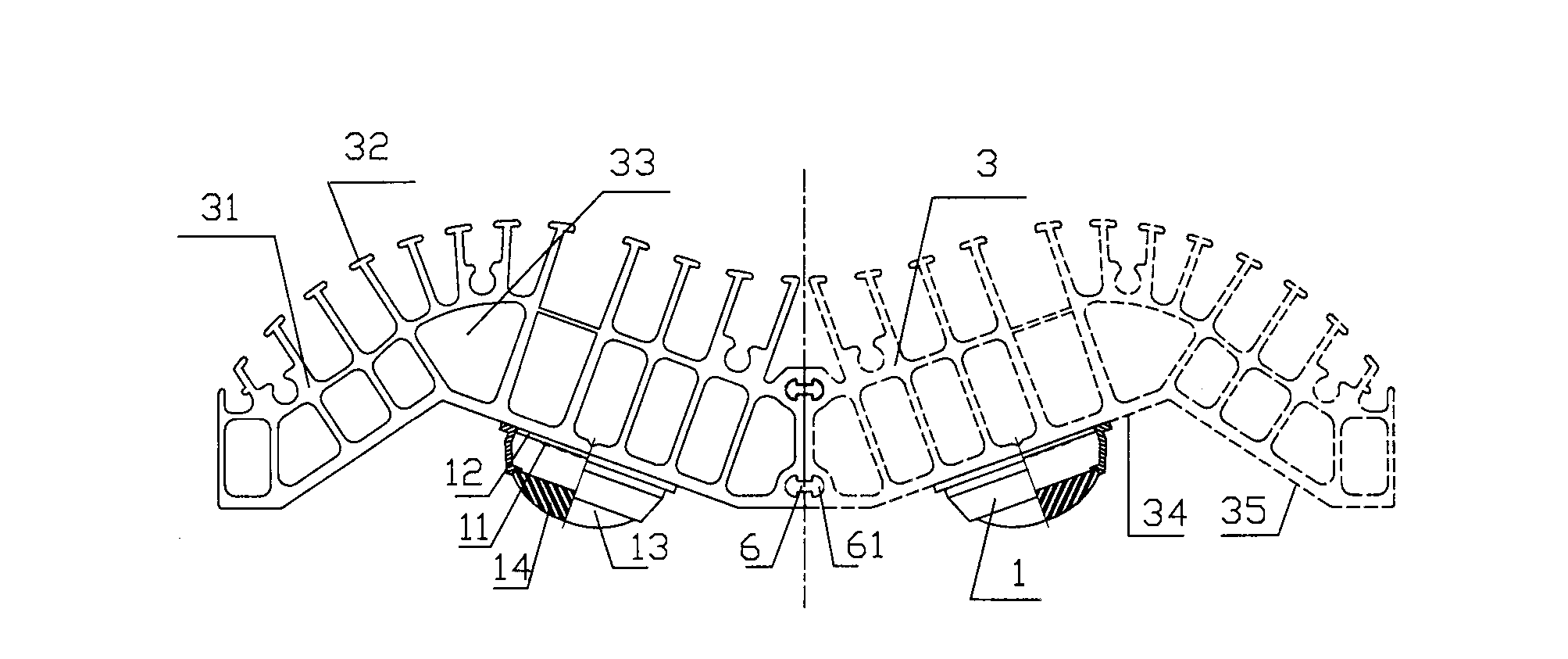

[0012] The specific implementation will be described in detail below in conjunction with the accompanying drawings: Figure 1 ~ Figure 2 One embodiment of the invention is shown. In the figure, an LED tunnel light is shown, which includes: an LED lamp base 1, a front cover 2, a radiator 3, and a tail cover 4. The LED lamp holder 1 is composed of a base plate 11, a number of single-chip LEDs 12, a lamp holder 13, and a convex lens 14. The lamp holder 13 is in the shape of a circular platform, and the upper part of the circular platform is provided with a shoulder 15 for accommodating the convex lens. The several single-chip LEDs 12 are fixed on the On the base plate 11, the base plate 11 is flush with the bottom surface of the lamp base 13, and the convex lens 14 is located on the shoulder of the base base. The radiator 3 is composed of a symmetrical double "herringbone"-shaped hollow columnar body 31 and fins 32 on the outer convex surface of the hollow columnar body. The hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com