Wind-powered lubrication system with pressure buffer

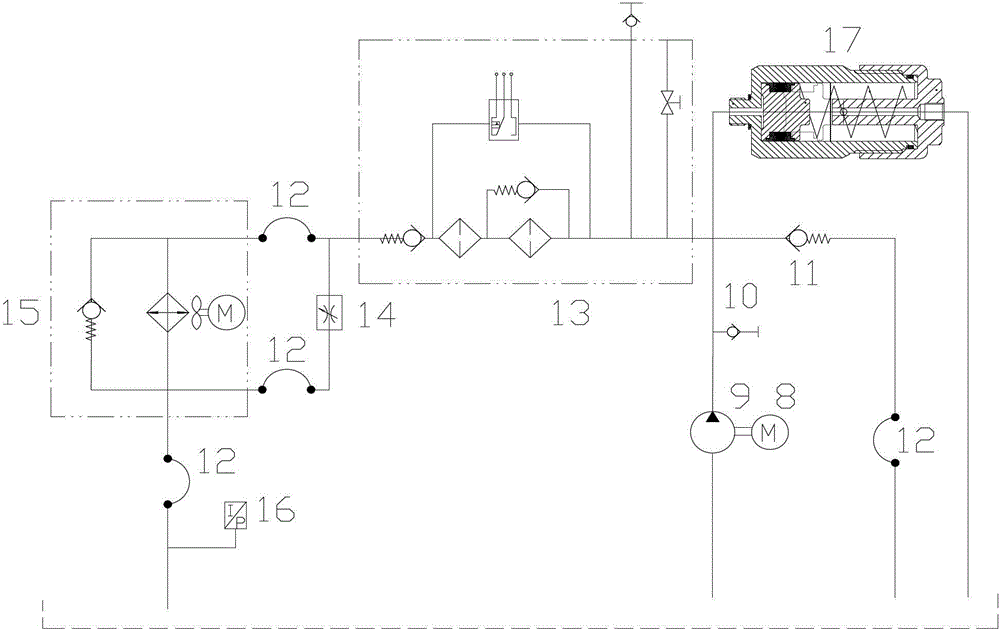

A lubricating system and buffer technology, which is applied in the direction of engine lubrication, lubricating parts, lubricating oil control valves, etc., can solve the problems of reducing the safety and reliability of the lubricating system, increasing the system failure rate, and the hazards of the lubricating system. The effects of modernization and mass production, improved safety performance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

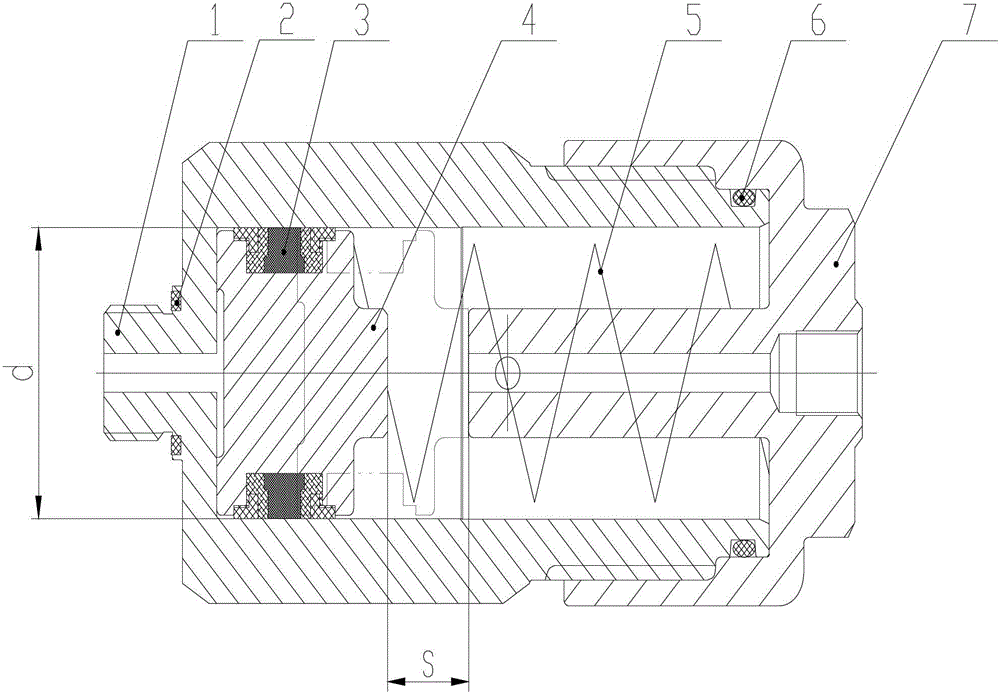

[0030] Embodiment 1 is an embodiment of the external guide of the return spring of the pressure buffer, such as image 3 shown. The piston 4 is provided with a travel pin 18, and the center of the travel pin 18 has a hole through the two ends, the hole diameter is the same as that of the center hole of the inner end shaft of the end cover, and the travel pin 18 is fixedly installed in the center of the abutment surface of the piston 4 and the return spring 5 In the pin hole at , the distance between the end face and the end face of the shaft-shaped table in the end cover 7 is s, 02 / 4k-S 0 , where p is the outlet pressure of the electric oil pump of the wind power lubrication system, p is 0.7MPa-2.8MPa, d is the diameter of the piston (4), k is the stiffness of the return spring 5, S 0 is the initial compression amount of the return spring (5) after assembly. The back-moving spring 5 is a butterfly spring, and the total gap between the outer circumference of the butterfly sp...

Embodiment 2

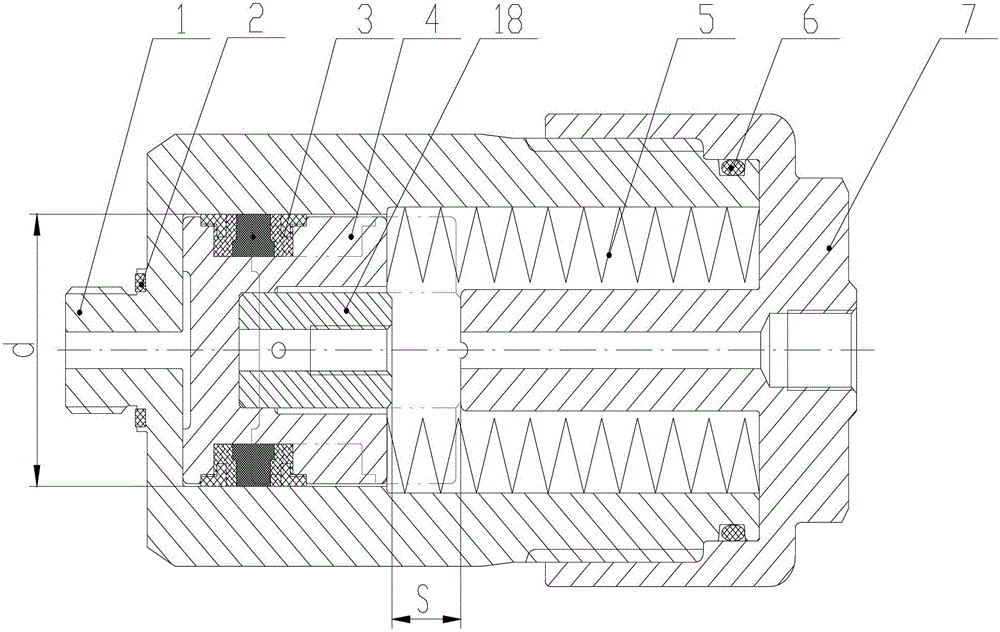

[0031] Embodiment 2 is an embodiment of guiding in the return spring of the pressure buffer, such as Figure 4 shown.

[0032]The piston is provided with the same travel pin as in Embodiment 1. A guide sleeve 19 is installed on the inner shaft-shaped platform of the end cover, and the guide sleeve 19 is sleeved on the inner shaft-shaped platform of the end cover. Above, the rear end surface of the guide sleeve 19 is in contact with the end cover 7, and there is a distance s between the front end surface and the bottom surface of the stroke pin hole of the piston, 02 / 4k-S 0 , where p is the outlet pressure of the electric oil pump of the wind power lubrication system, p is 0.7MPa-2.8MPa, d is the diameter of the piston, k is the stiffness of the return spring, S 0 For the initial compression of the return spring after assembly, the return spring 5 is placed outside the guide sleeve 19 . Back-moving spring 5 is a butterfly spring, and the total gap between the inner circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com