Engine sump

A technology of engine oil and oil pan, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve problems such as seepage, rough structure of oil pan, drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention will be further described;

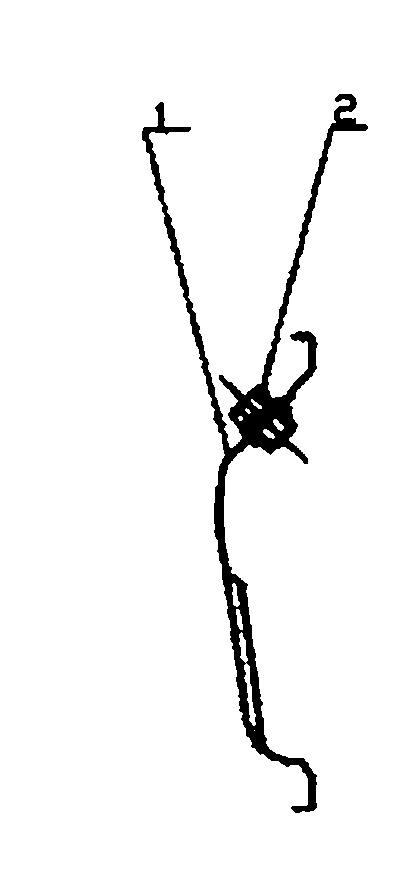

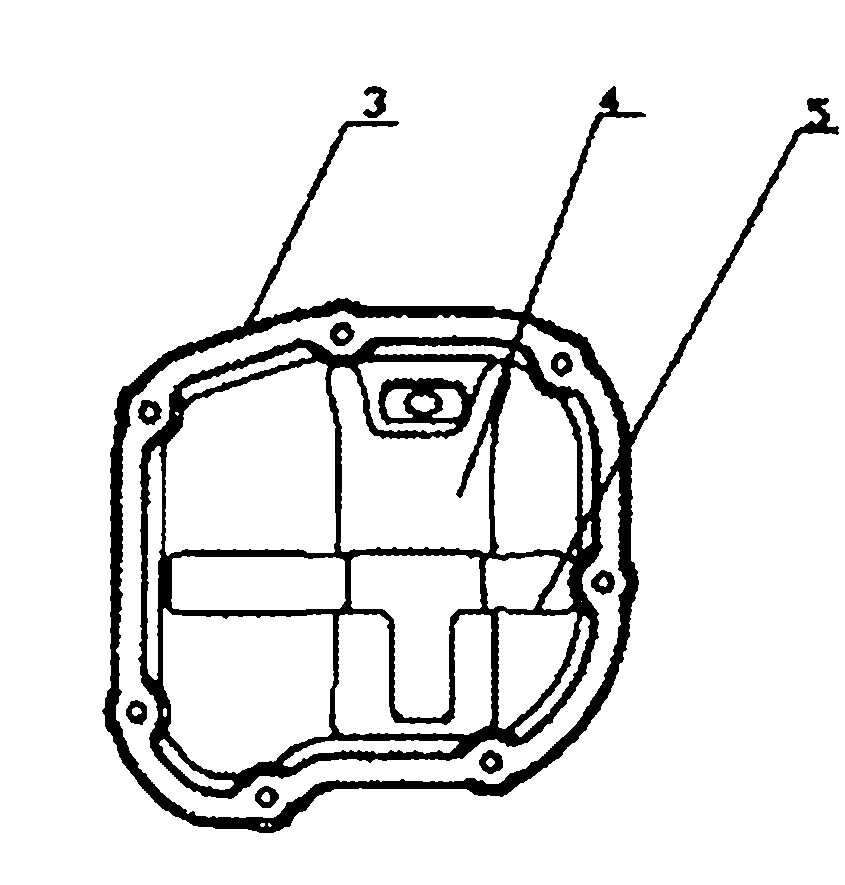

[0008] The engine oil pan consists of a large end surface 3, an oil pan inner cavity 4, a rear end surface 1 and an oil pan bottom 5, and is characterized in that: inner cavity ribs are arranged in the oil pan inner cavity 4; The bottom 5 is provided with bottom ribs; the rear end surface 1 of the oil pan is provided with rear end gluten; the rear end surface 1 of the oil pan is designed as a semicircle to match the shape of the end surface of the gearbox case, and the Two bolt holes for connecting the oil pan and the gearbox are added on the rear end surface 1, so that the oil pan can be directly connected with the gearbox case. During the specific implementation, the mold is designed according to the requirements of the drawings, and the material of ST14-1.4 is used to process the oil bottom shell through several drawing, stamping, punching and trimming. Reinforcing rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com