Hydraulic bracket control device with personal safety protection function and control method thereof

A technology of hydraulic support and protection function, applied in mine roof support, earthwork drilling, mining equipment, etc., can solve the problems of hydraulic support damage, slowness, and small working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

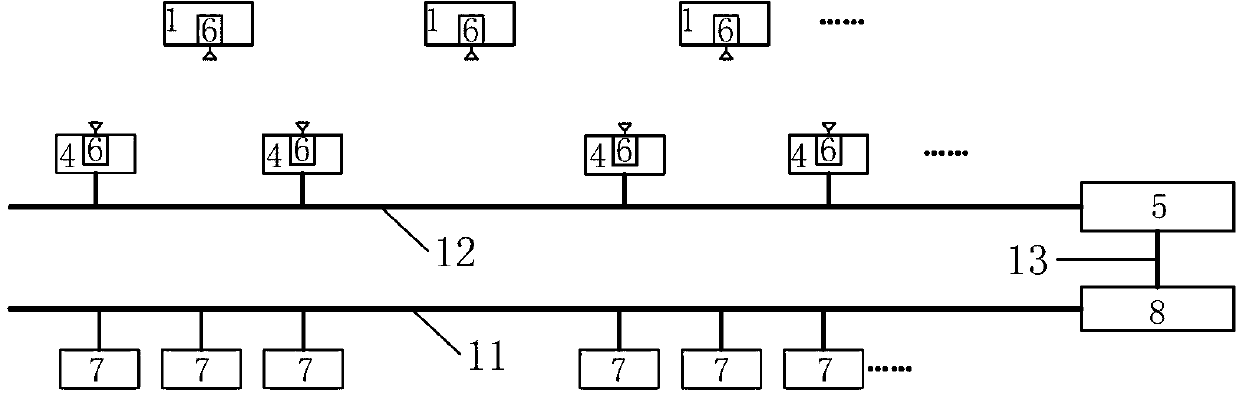

[0047] Such as figure 1 As shown, the hydraulic support control device with personal safety protection function in Embodiment 1 includes: a hydraulic support electro-hydraulic control host 8 installed along the groove of the working surface, a number of hydraulic support controllers 7 installed on the hydraulic support, wherein the hydraulic support The controller 7 is in one-to-one correspondence with the hydraulic supports; it also includes a non-blind zone communication network arranged in the fully mechanized mining face. The non-blind zone communication network in embodiment 1 includes a personnel positioning wireless transceiver 1 carried by personnel in the working face It is also possible to replace the personnel positioning wireless transceiver 1 with a personnel positioning wireless transmitter; at least two wireless transceiver base stations 4 installed on hydraulic supports or scraper conveyors, and at least two wireless transceiver base stations 4 are used to faci...

Embodiment 2

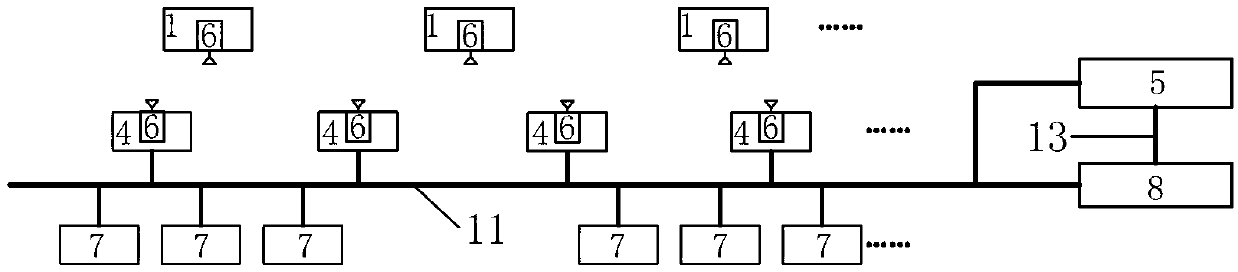

[0057] Embodiment two is basically the same as embodiment one, the difference is: Figure 6 The non-blind zone communication network of the shown embodiment two is in figure 1 On the basis of the non-blind zone communication network of the shown embodiment one, a hand-held remote control wireless transceiver 3 carried by the operator of the hydraulic support is added; the hand-held remote control wireless transceiver 3 is provided with a wireless transceiver module 6, and the wireless transceiver module 6 is at least Including a wireless transceiver controller and a transceiver antenna, the wireless transceiver module 6 has a unique identification number, which can be a MAC code or an ID code.

[0058] Figure 7-Figure 10 for Figure 6 There are several other optional modes of the second embodiment shown.

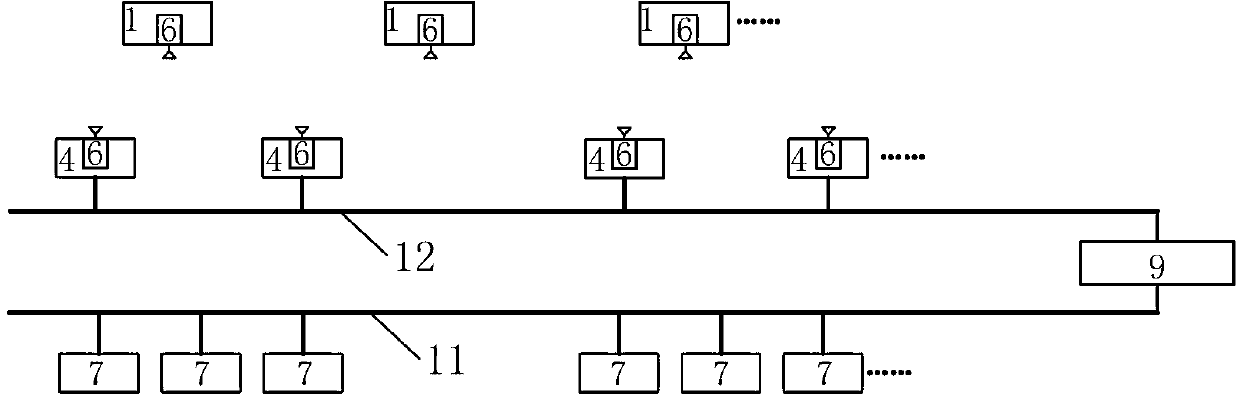

[0059] Such as Figure 7 as shown, Figure 7 and figure 2 Basically the same, the difference is: in figure 2 On the basis of the non-blind zone communication netw...

Embodiment 3

[0064] Embodiment three is basically the same as embodiment two, the difference is: Figure 11 The non-blind zone communication network of the shown embodiment three is in Figure 6 On the basis of the non-blind zone communication network of the shown embodiment two, the airborne wireless transceiver 10 installed on the coal mining machine is added, and the airborne wireless transmitter 10 can also be replaced by the airborne wireless transmitter; The device 10 is provided with a wireless transceiver module 6, the wireless transceiver module 6 at least includes a wireless transceiver controller and a transceiver antenna, and the wireless transceiver module 6 has a unique identification number, which can be a MAC code or an ID code;

[0065] When using an airborne wireless transmitter, the airborne wireless transmitter is provided with a wireless transmitting module, the wireless transmitting module at least includes a wireless transmitting controller and a transmitting antenna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com