Overhead attached type vertical steel pipe truss for assisting in mounting pump pipe and construction method thereof

A technology of steel pipe truss and construction method, which is applied in the erection/assembly of bridges, the processing of building materials, bridges, etc., which can solve the problems of long installation period, increased project cost, and poor resistance to dynamic loads, so as to improve bearing capacity and stability Performance, improve work efficiency, increase the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

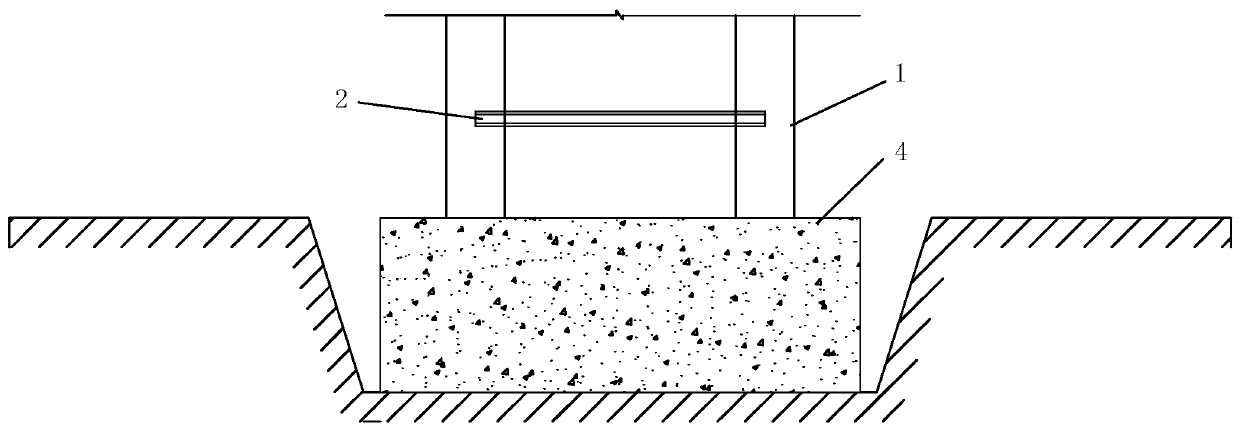

[0069] A volley attached vertical steel pipe truss for assisting in the installation of pump pipes, the truss includes a truss steel pipe column 1, a truss cross bar 2, a truss attachment bar 3 and a truss foundation 4; there are two truss steel pipe columns, two truss The steel pipe columns 2 are installed and fixed on the truss foundation 4 at a certain distance, and the opposite sides of the two truss steel pipe columns are respectively connected by welding a plurality of truss cross bars 2; A long truss internal space is provided, which is used for the installation and maintenance of the pump pipe standpipe; the truss attachment rod 3 is arranged on the upper part of the truss steel pipe column, and is located in the middle of the left and right sides of the main bridge on the top of the truss. The truss attachment rods are fixedly connected to the main body 6 of the bridge structure through embedded iron pieces 32 .

[0070] The truss in this embodiment is composed of two...

Embodiment 2

[0079] A construction method for a volley-attached vertical steel pipe truss used to assist in the installation of pump pipes, which is a construction method for the volley-attached vertical steel pipe truss used to assist in the installation of pump pipes as described in Embodiment 1. The construction process is: A. Construction preparation→B. Truss component blanking, prefabrication→C. Truss foundation construction→D. Truss volley installation and fixation→E. Concrete pump pipe riser installation→F. .

[0080] The operation points of each step are as follows:

[0081] Described step A, construction preparation

[0082] (1) Technical preparation

[0083] 1. Carry out truss deployment, design and force checking calculations and prepare special construction plans, organize relevant personnel to study process regulations and make technical disclosures.

[0084] 1) Load calculation

[0085] φ600*8 steel pipe weight 0.117*21*2*10=49.14KN

[0086] 12# channel steel weight 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com