Solvent-free double-constituent polyurethane compound adhesive and preparation method for same

A two-component polyurethane and adhesive technology, applied in the field of polymer chemistry, can solve problems such as inability to coat, weaken composite fastness, and affect appearance, and achieve the effects of reducing production costs, increasing production speed, and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

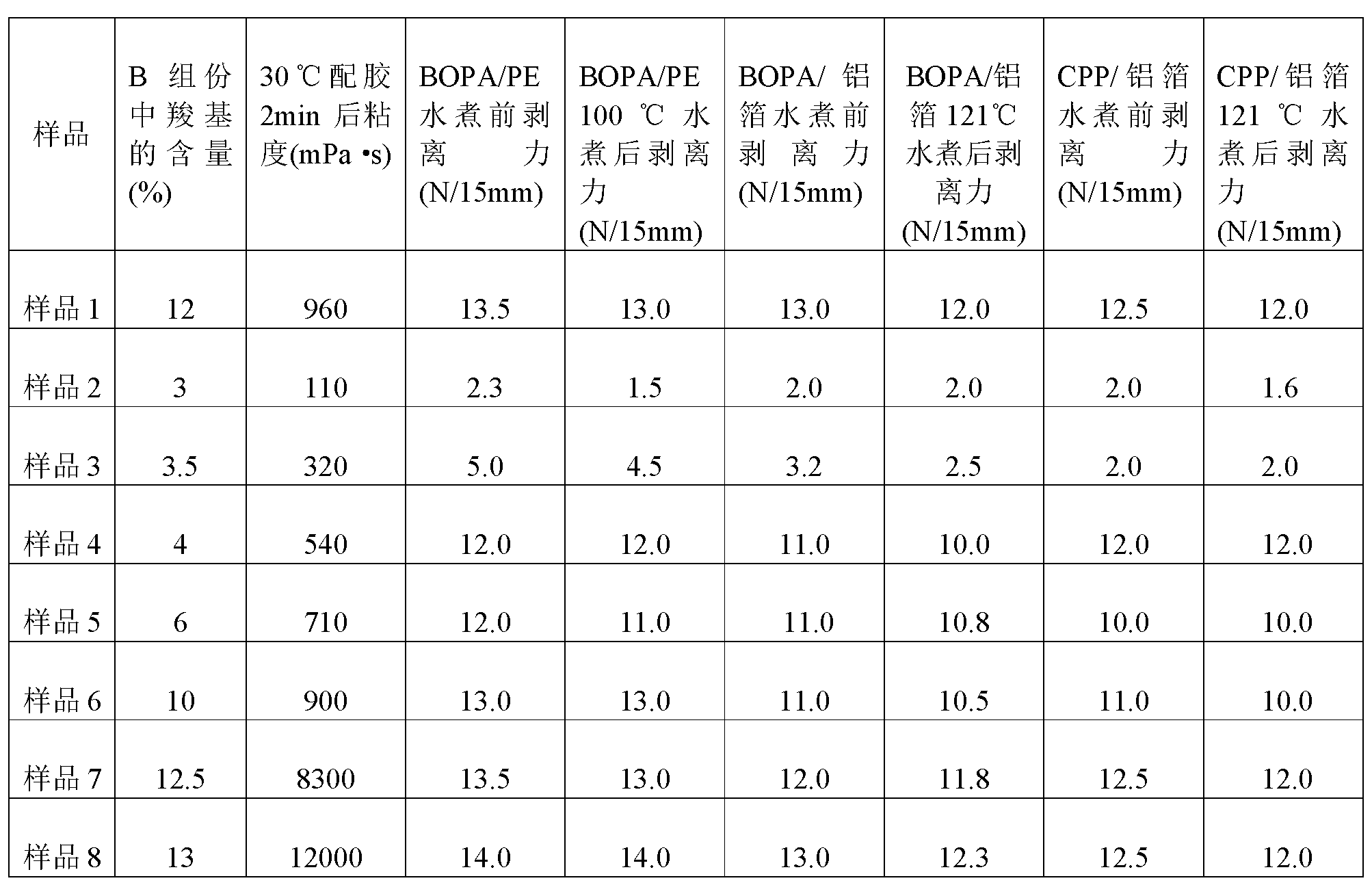

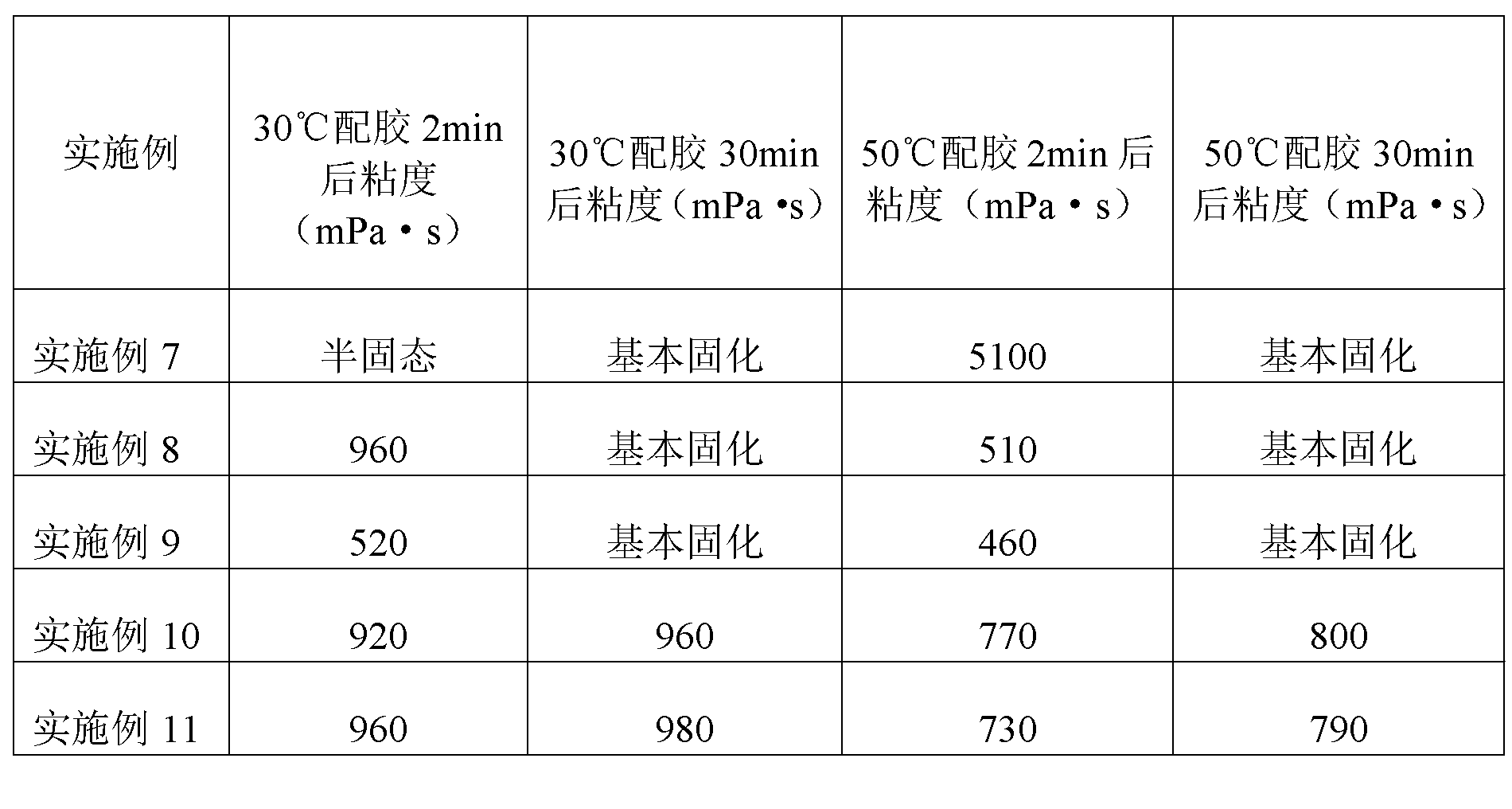

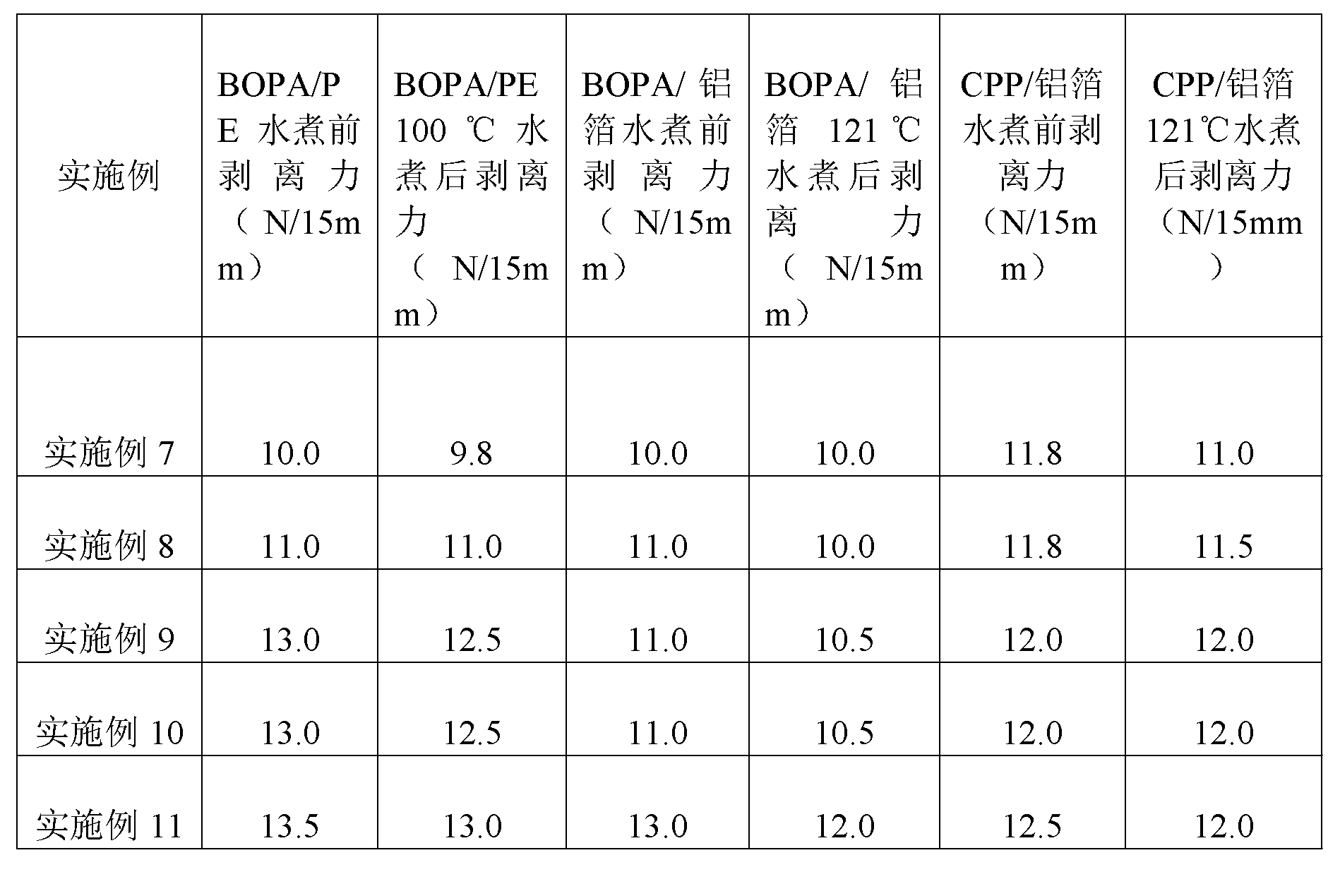

Examples

Embodiment 1

[0058] Embodiment 1: the preparation of A-1

[0059] Under the protection of nitrogen, heat 65 parts of polyoxypropylene diol with a molecular weight of 400 and 60 parts of polyoxypropylene triol with a molecular weight of 300 to 130°C, under a vacuum of 0.266KPa, dehydrate for 1.5h and then take a sample to measure the moisture content. When the content is less than 0.05%, cool down to 70°C, add 150 parts of HMDI and 125 parts of IPDI, and react at 85°C for 2 hours to obtain component A (hereinafter referred to as A-1).

Embodiment 2

[0060] Embodiment 2: the preparation of A-2

[0061] Under the protection of nitrogen, 120 parts of polyoxypropylene triol with a molecular weight of 300 and 80 parts of a soybean oil-modified polyol with a molecular weight of 1000 (functionality 2.6) were heated to 150 ° C, and the vacuum degree was 0.266 KPa. After dehydration for 2 hours, samples were taken for water measurement. When the water content is less than 0.05%, cool down to 60°C, add 150 parts of HMDI and 50 parts of IPDI, and react at 120°C for 2.5 hours to obtain component A (hereinafter referred to as A-2).

Embodiment 3

[0062] Embodiment 3: the preparation of A-3

[0063] Under the protection of nitrogen, 60 parts of polyoxypropylene diol with a molecular weight of 400 and 40 parts of castor oil-modified trihydric alcohol with a molecular weight of 900 were heated to 140 ° C, and under a vacuum of 0.266 KPa, after dehydration for 2 hours, samples were taken to measure the moisture content. When the water content is less than 0.05%, cool down to 70°C, add 200 parts of HMDI and 100 parts of IPDI, and react at 90°C for 3 hours to obtain component A (hereinafter referred to as A-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com