Bare concrete binding material and corrosion-resistant bare concrete utilizing same

A technology of fair-faced concrete and cementitious materials, which is applied in cement production and other directions, can solve the problems of concrete structure being corroded by chloride ions, affecting the service life of concrete structure, and large structure section size, so as to improve the resistance to chloride ion penetration and chlorine resistance Good ion permeability and the effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The anti-corrosion fair-faced concrete mix example of the present invention is shown in Table 1.

[0016] Table 1

[0017]

[0018] The water reducer is preferably HSP-V polycarboxylate water reducer from Sihang Material Company.

[0019] The slump of the concrete mixture prepared in the above three examples is 180~185mm, the air content is 3.0~3.2%, the color of the hardened concrete is off-white, the color is uniform, and there is no obvious color difference. Concrete mixture refers to the plastic state mixture that has not yet set and hardened when the various components of concrete are mixed in a certain proportion, also known as fresh concrete. The working properties, mechanical properties and durability of the above three examples of concrete are shown in Table 2.

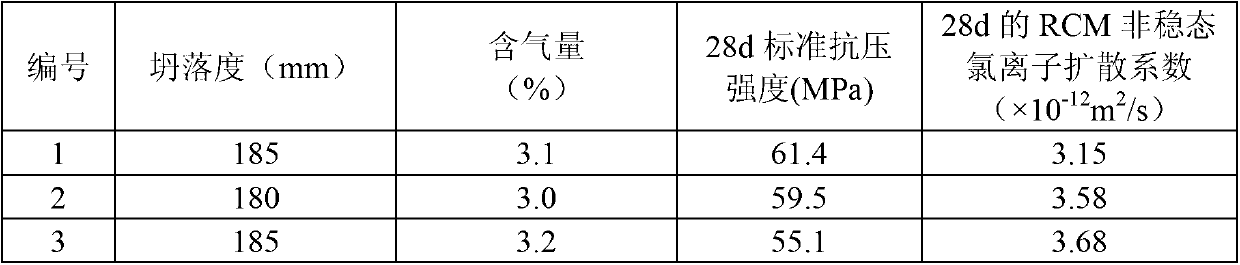

[0020] Table 2

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com