Carbon fiber composite, preparation method thereof and tank

A composite material and carbon fiber technology, applied in the field of composite materials, can solve the problems of increasing the manufacturing cost of tank cars, the economic benefits are not obvious, and the carbon fiber is expensive, and achieve the effect of reducing fuel consumption and carbon dioxide emissions, reducing production costs, and improving operating profits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Carbon fiber composite material tank and its preparation method

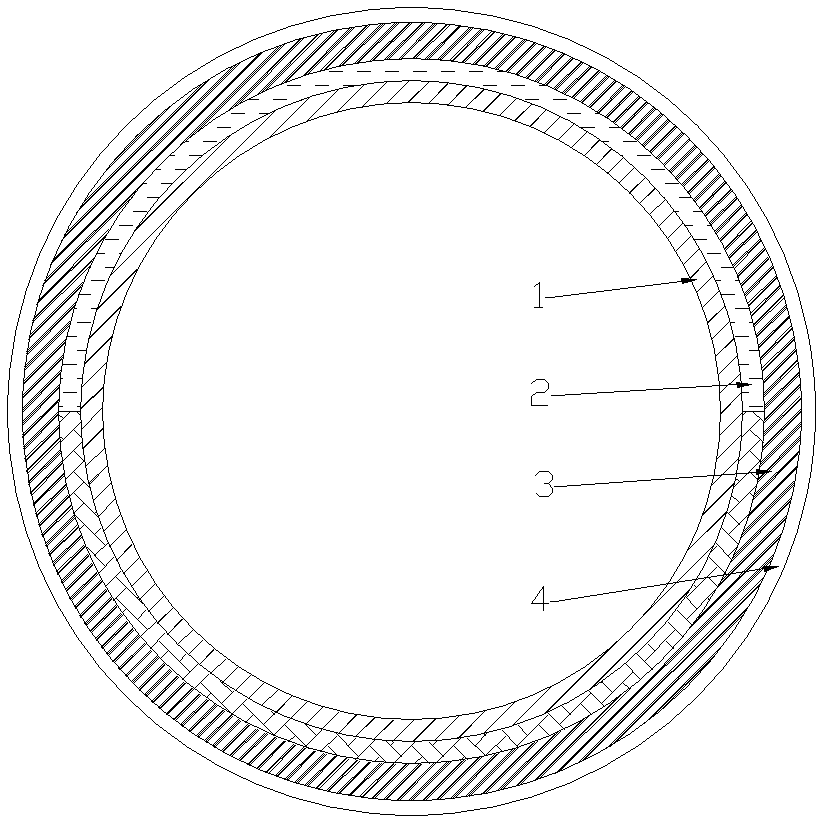

[0039] 1. If figure 1 As shown, the tank body of the tank in this embodiment is made of carbon fiber composite material, including a metal inner layer 1 , a local reinforcement layer 2 , a reinforcement layer 3 and an outer protective layer 4 . The thickness of each layer is: metal inner layer 3mm, local reinforcement layer 10mm, reinforcement layer 15mm, outer protective layer 3mm.

[0040] 2. If figure 2 Shown, the preparation method of the tank of the present embodiment comprises the following steps:

[0041] 1) According to the structure design of the tank, the metal inner layer is made of cemented carbide material; the metal inner layer is treated as a base, and the surface of the inner layer is polished and degreased by sandblasting.

[0042] 2) Spread the twill fabric woven by Toray T700 type 24K carbon fiber and the vinyl resin glue containing the initiator cyclohexanone peroxide (CH...

Embodiment 2

[0045] Example 2 Carbon fiber composite material tank and its preparation method

[0046] 1. If figure 1 As shown, the tank body of the tank in this embodiment is made of carbon fiber composite material, including a metal inner layer 1 , a local reinforcement layer 2 , a reinforcement layer 3 and an outer protective layer 4 . The thickness of each layer is: metal inner layer 5mm, local reinforcement layer 15mm, reinforcement layer 20mm, outer protective layer 5mm.

[0047] 2. prepare the tank of the present embodiment by the same method as in embodiment 1, the difference is:

[0048] 1) Use steel material to make the metal inner layer; use a wire brush to polish and degrease the surface of the inner layer.

[0049] 2) The 3 / 4 part of the partial reinforcement layer is hand-laid layer by layer with 24K carbon fiber woven plain cloth and bismaleamide resin prepolymer, and the remaining 1 / 4 part is pre-laid with chopped basalt fiber felt and bismaleamide resin. The polymer is ...

Embodiment 3

[0052] Example 3 Carbon fiber composite material tank and its preparation method

[0053] 1. If figure 1 As shown, the tank body of the tank in this embodiment is made of carbon fiber composite material, including a metal inner layer 1 , a local reinforcement layer 2 , a reinforcement layer 3 and an outer protective layer 4 . The thickness of each layer is as follows: metal inner layer 1mm, local reinforcement layer 8mm, reinforcement layer 10mm, outer protective layer 1mm.

[0054] 2. prepare the tank of the present embodiment by the same method as in embodiment 1, the difference is:

[0055] 1) The metal inner layer is made of aluminum material; the surface of the inner layer is polished and degreased by sandblasting.

[0056] 2) The 2 / 3 part of the local reinforcement layer is laid layer by layer with 24K carbon fiber stitched fiber cloth and unsaturated polyester resin mixed glue containing initiator benzoyl peroxide and accelerator diethylaniline curing system, The rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com