Automatic chamfering machine

A chamfering machine and automatic technology, applied in the field of machining, can solve the problems of low efficiency, low precision, troublesome positioning, etc., and achieve the effect of high degree of automation, improving work efficiency and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

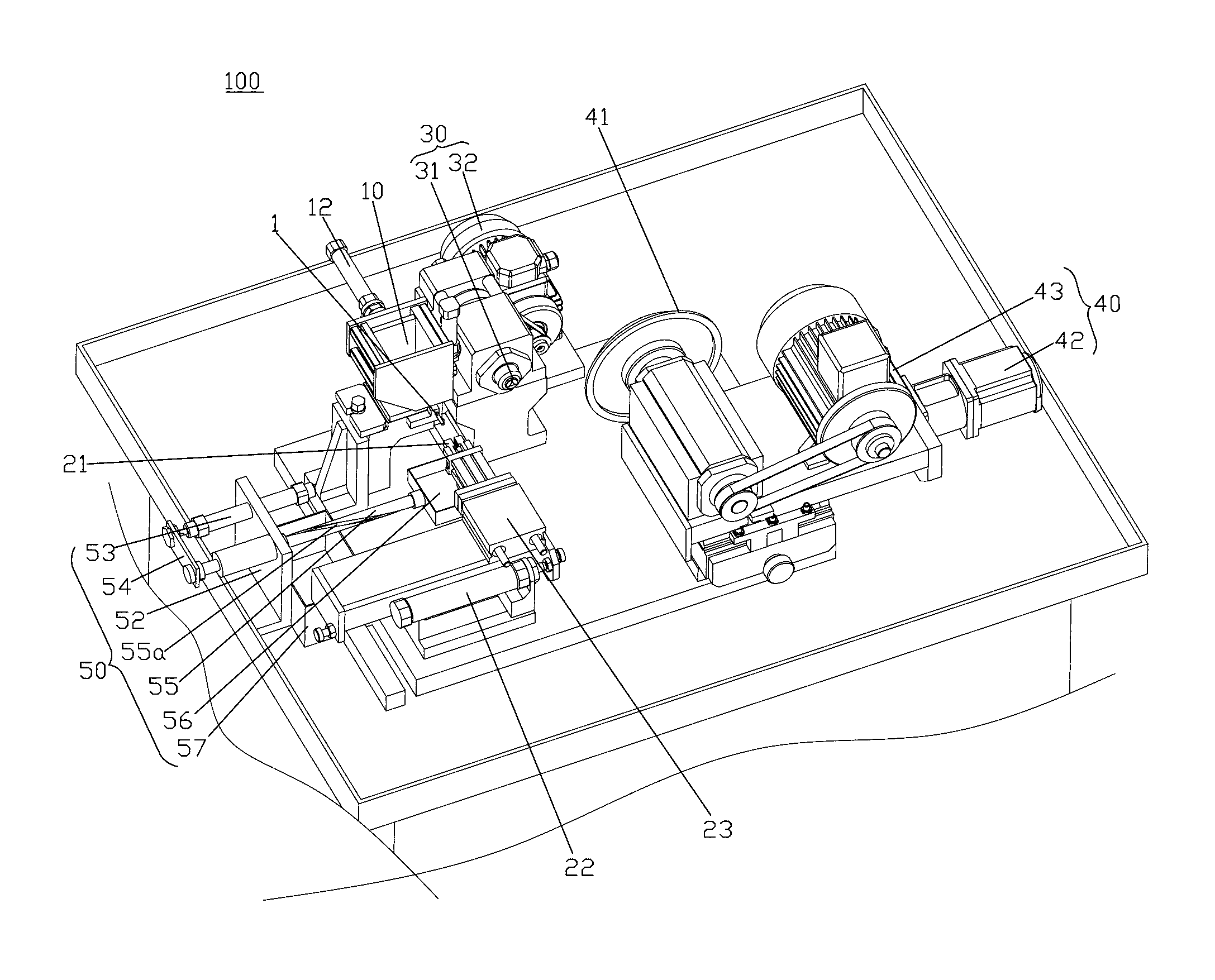

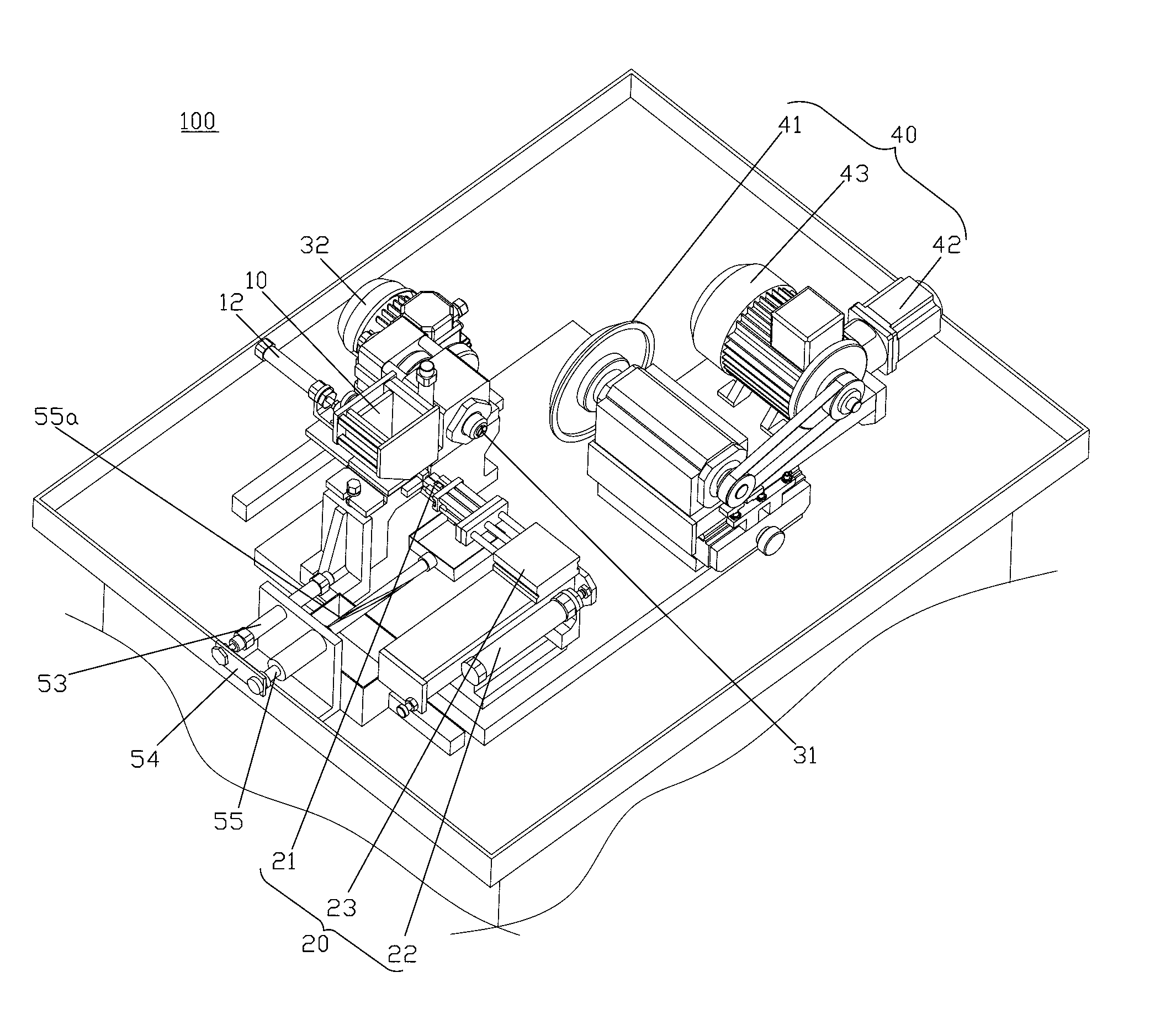

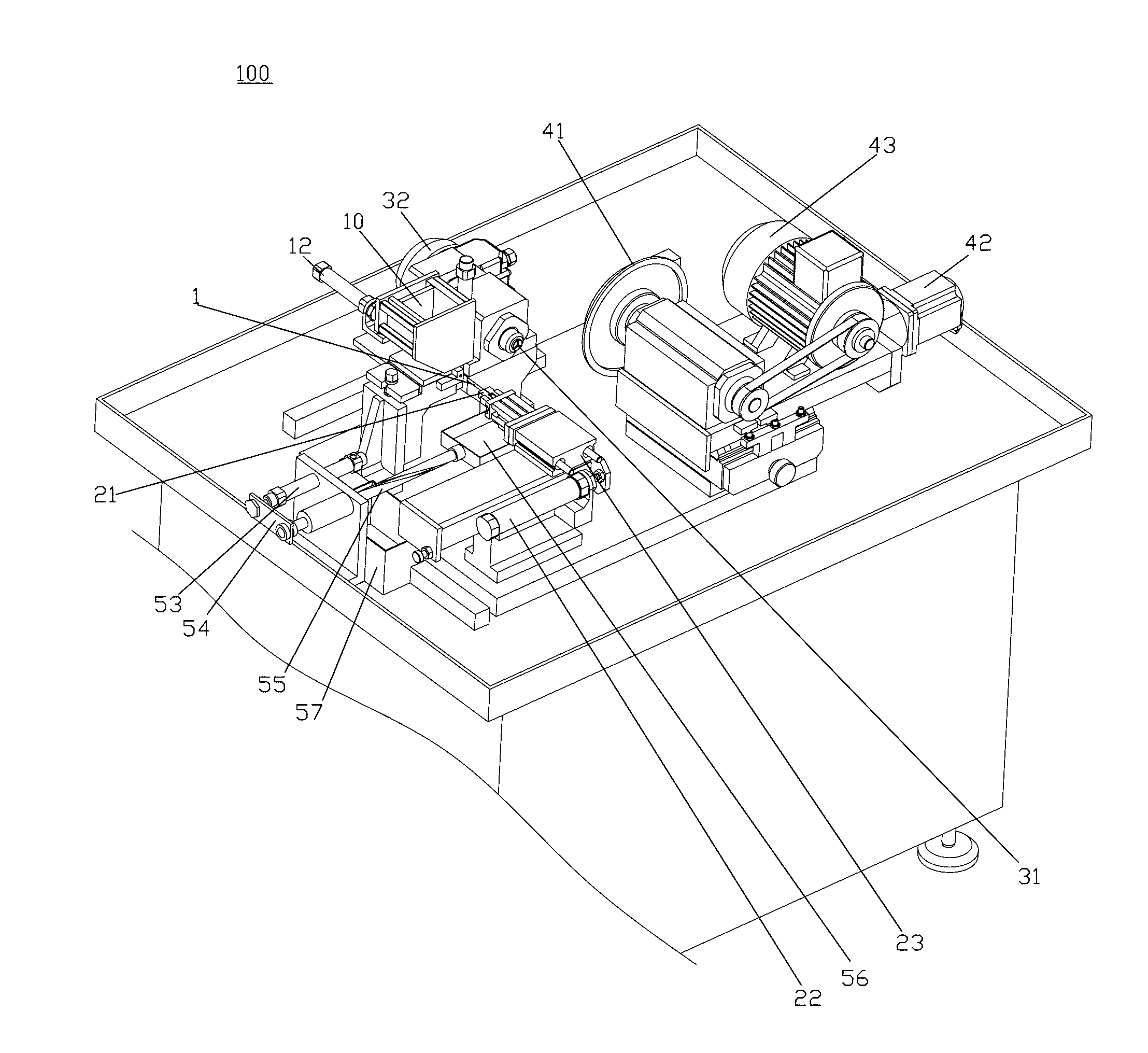

[0024] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as Figure 1-5 As shown, the automatic chamfering machine 100 provided by the present invention is used for chamfering cylindrical workpieces, including: feeding trough 10, transfer mechanism 20, clamping device 30 and grinding disc device 40, in the layout of an embodiment , the transfer mechanism 20 and the grinding disc device 40 are arranged on one side, and the feeding trough 10 and the clamping device 30 are arranged on the other side.

[0025] The feed trough 10 is in the shape of an inverted pyramid with a large top and a small bottom, and a groove (not shown in the figure) that just accommodates a workpiece 1 is provided at the bottom. The workpiece 1 to be processed is placed in the feed trough 10, and the bottom is There is a discharge port (not shown in the figure) for the extraction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com