Method for producing steel wire for steel core of ultrahigh-strength overhead cable by using 82B steel wire rod

An overhead cable and ultra-high-strength technology, which is applied in the field of producing ultra-high-strength overhead cable steel core steel wire with 82B wire rod, can solve the problems of unqualified torsional performance, steel wire toughness damage, environmental pollution, etc., to reduce heat treatment processes and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Production of galvanized steel strand for G4A 7 / 1.95 (1×7-5.85mm):

[0023] The composition and weight percentage of 82B used are C: 0.82%, Si: 0.22%, Mn: 0.75%, S<0.01%, P<0.01%, and the rest is Fe and unavoidable trace impurities; the diameter of the wire rod is D is 5.5mm, the initial tensile strength is 1160MPa, the reduction of area is 32%, the grain size is 8 grades, the sorbite content is 90%, the steel wire diameter d is 1.95mm, and the running speed v of steel wire galvanizing is 46.2m / min, the number of pressing passes n is 11 times.

[0024] Its production steps:

[0025] 1) Select 82B wire rod with a diameter of 5.5mm and an initial tensile strength of 1160MPa;

[0026] 2) Carry out conventional pickling and phosphating treatment, and the phosphating film layer on the surface of the wire rod after phosphating treatment is uniform;

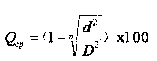

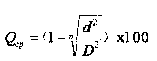

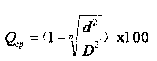

[0027] 3) Drawing is carried out, the drawing pass n is 11 times, the average reduction rate of each pass is 17.2%...

Embodiment 2

[0033] Example 2: Production of galvanized steel strand for G4A 7 / 2.10 (1×7-6.30mm):

[0034] The composition and weight percentage of 82B used are C: 0.81%, Si: 0.24%, Mn: 0.78%, S<0.01%, P<0.01%, and the rest is Fe and unavoidable trace impurities; the diameter of the wire rod is D 6.5mm, the initial tensile strength is 1160MPa, the reduction of area is 32%, the grain size is 8 grades, the sorbite content is 90%, the steel wire diameter d is 2.10mm, and the running speed v of steel wire galvanizing is 45m / min, the number of pressing passes n is 11 times.

[0035] Its production steps:

[0036] 1) Select 82B wire rod with a diameter of 6.5mm and an initial tensile strength of 1160MPa;

[0037] 2) Carry out conventional pickling and phosphating treatment, and the phosphating film layer on the surface of the wire rod after phosphating treatment is uniform;

[0038] 3) Drawing is carried out, the drawing pass n is 11 times, the average reduction rate of each pass is 18.6%, t...

Embodiment 3

[0044] Example 3: Production of galvanized steel strand for G4A 19 / 2.50 (1×19-12.50mm):

[0045] The composition and weight percentage of 82B used are C: 0.81%, Si: 0.25%, Mn: 0.80%, S<0.01%, P<0.01%, and the rest is Fe and unavoidable trace impurities; the diameter of the wire rod is D 8.0mm, the initial tensile strength is 1160MPa, the reduction of area is 32%, the grain size is 8 grades, the sorbite content is 90%, the steel wire diameter d is 2.50mm, and the running speed v of steel wire galvanizing is 44m / min, the number of pressing passes n is 11 times.

[0046] Its production steps:

[0047] 1) Select 82B wire rod with a diameter of 8.0mm and an initial tensile strength of 1160MPa;

[0048] 2) Carry out conventional pickling and phosphating treatment, and the phosphating film layer on the surface of the wire rod after phosphating treatment is uniform;

[0049] 3) Drawing is carried out, the drawing pass n is 11 times, the average reduction rate of each pass is 19.1%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com