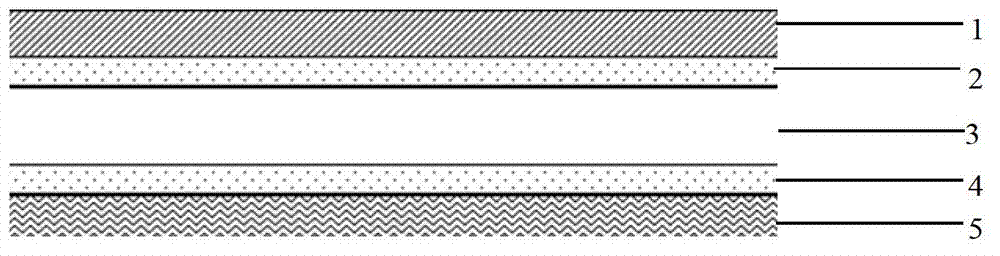

Coating method and system of coating film meeting requirements of sandwich food package and coated with PVDC (Polyvinyl Dichloride) emulsion on double faces

A food packaging and double-sided coating technology, applied in the field of coating systems, can solve the problems of film shrinkage and deformation, poor packaging and sealing, sandwich deformation, etc., and achieve the effect of improving adhesion and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Unwinding process: Under a constant unwinding tension of 20N, the BOPP reel-shaped film with a thickness of 22 μm is flatly unwound into a continuous and stable operation;

[0032] 2. The first surface corona treatment process: the corona treatment power is set to 6.0kW, and the corona value of the treated base film reaches 41 dynes;

[0033] 3. The first side primer coating process: the solvent-based polyurethane adhesive is coated on the BOPP film through a metal chrome-plated anilox roller, and the glue amount of the adhesive on the film is 0.3g / m 2 , the coating thickness is 1μm, the number of metal anilox roller lines is 150 lines, and the machine running speed is controlled at 200m / min;

[0034] 4. The drying process of the first side primer: use hot air to dry, and then send it into the oven after the air is heated. The temperature is set at 100°C, and the drying time of the film in the oven is 1 second. The tension is set to 90N;

[0035] 5. The first surfa...

Embodiment 2

[0045] 1. Unwinding process: Under a constant unwinding tension of 30N, the BOPP reel-shaped film with a thickness of 28 μm is flatly unwound into a continuous and stable operation;

[0046] 2. The first surface corona treatment process: the corona treatment power is set to 6kW, and the corona value of the base film after treatment reaches 41 dynes;

[0047] 3. The first side primer coating process: the solvent-based polyurethane adhesive BOPP is coated on the film through a metal chrome-plated anilox roller, and the glue amount of the adhesive on the film is 0.4g / m 2 , the coating thickness is 1μm, the number of metal anilox roller lines is 200 lines, and the machine running speed is controlled at 200m / min;

[0048] 4. The drying process of the first side primer: use hot air to dry, and then send it into the oven after the air is heated. The temperature is set at 100°C, and the drying time of the film in the oven is 1 second. The tension is set to 90N;

[0049] 5. The first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com