Silver film resistor-type atomic oxygen sensor, atomic oxygen detector and application methods thereof

An application method, atomic oxygen technology, applied in the direction of material resistance, etc., can solve problems such as large measurement error, slow reaction rate, and poor response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

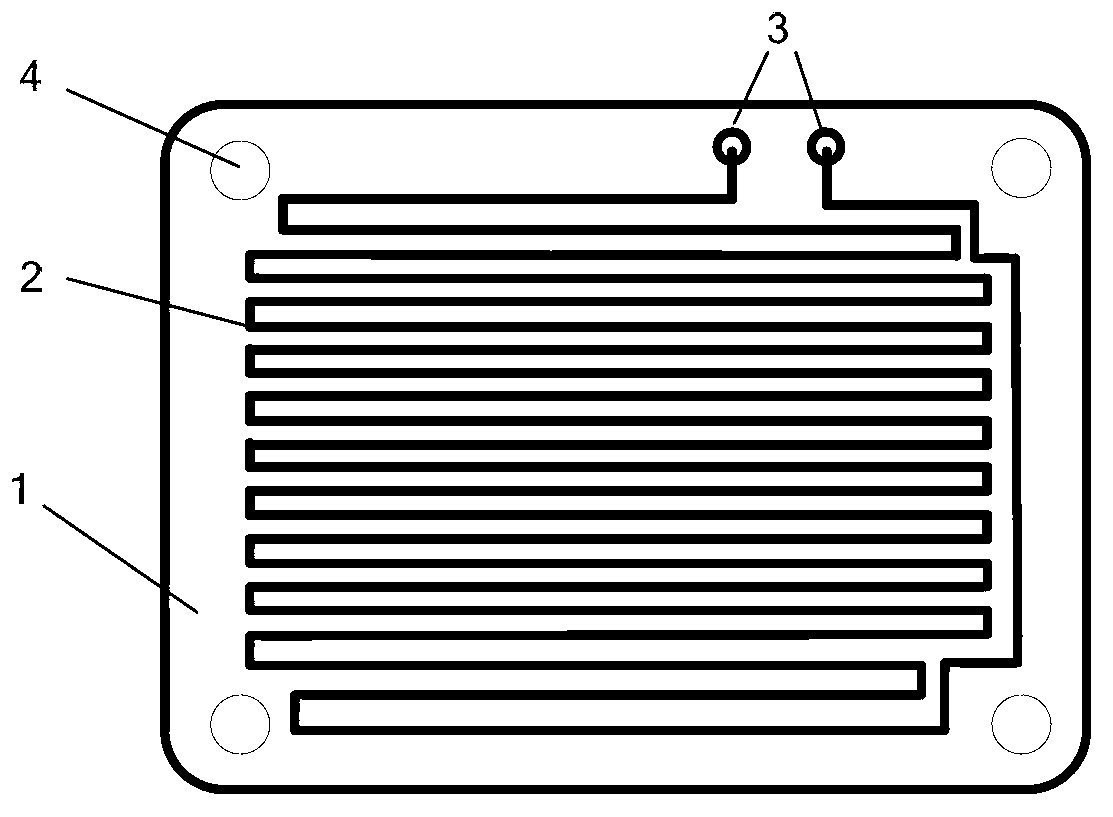

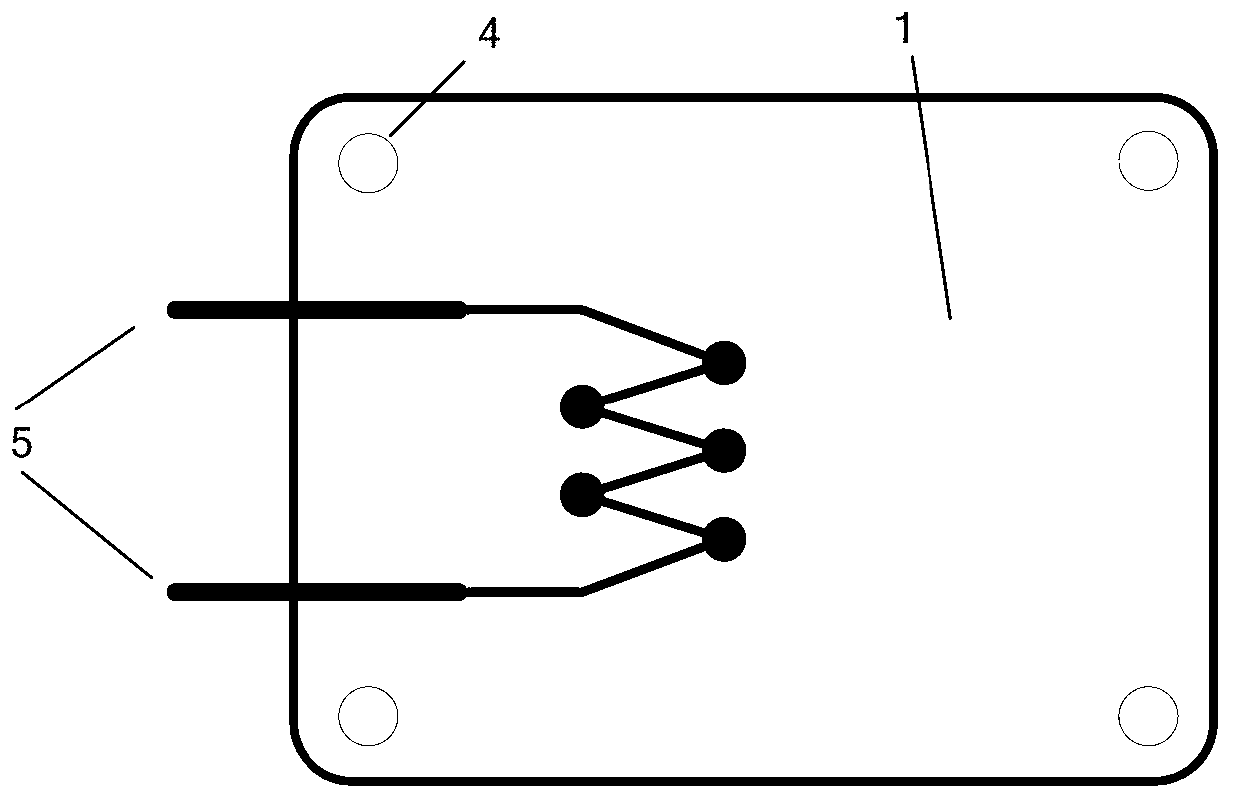

[0049] see figure 1 , the silver film resistive atomic oxygen sensor of the present invention comprises an alumina ceramic substrate 1 on which a silver film resistance wire 2 is arranged, and the lines of the silver film resistance wire 2 are arranged on the alumina ceramic substrate 1 in a zigzag shape Above, the two ends of the silver film resistance wire 2 are provided with metal electrodes 3 respectively.

[0050] The invention adopts the silver film resistance wire 2 to measure the intensity of atomic oxygen erosion, has small volume, light weight and low power consumption, and the silver film resistance has high reaction rate, high detection sensitivity and high measurement precision. In addition, the lines of the silver film resistance wire 2 are arranged in a "zigzag" shape, and the longest possible line can be arranged in a limited space, so that the resistance change of the silver film resistance wire 2 caused by atomic oxygen erosion can be more easily measured, ma...

Embodiment 2

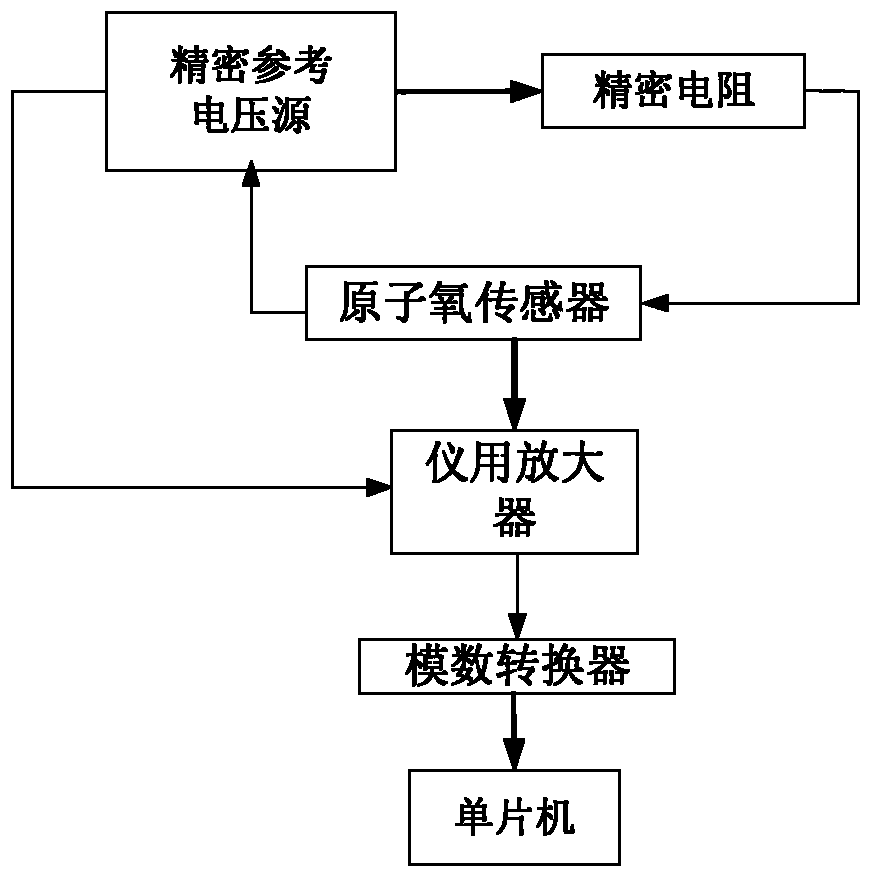

[0054] see image 3 , the atomic oxygen detector of the present invention includes the atomic oxygen sensor of embodiment 1, and also includes a precision voltage reference source, a precision resistor, an instrument amplifier and a single-chip microcomputer. Wherein, the metal electrodes 3 at both ends of the silver film resistance wire 2 on the atomic oxygen sensor are respectively connected to instrument amplifiers for real-time measurement of the resistance value of the silver film resistance wire 2 . The instrument amplifier is used to amplify the voltage signal at both ends of the atomic oxygen sensor into the sampling voltage of the single-chip microcomputer and then transmit it to the single-chip microcomputer; the single-chip microcomputer is used to calculate the resistance value of the atomic oxygen sensor in real time according to the value of the sampling voltage. The precision voltage reference source provides a voltage source for the series-connected precision r...

Embodiment 3

[0059] see Figure 4 , the present invention detects the application method of the atomic oxygen flux of spacecraft orbital space with the atomic oxygen detector of embodiment 2, comprises the following steps:

[0060] S1: Measure and record the initial resistance value R of the atomic oxygen sensor in Example 1 at 0°C 0 .

[0061] S2: Install the atomic oxygen sensor on the windward surface of the spacecraft, measure and calculate the first resistance value R of the atomic oxygen sensor at the first time point of the unit time interval through the single-chip computer 1 and a second resistance value R at a second time point 2 , and measure the first temperature value T at the first time point on the atomic oxygen sensor 1 and the second temperature value T at the second time point 2 .

[0062] In this embodiment, it is preferable to use the following formula to calculate the first resistance value R 1 :

[0063] R 1 = ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com