Anti-wind device improving heat exchange capability of direct air-cooling unit

A technology of air-cooled units and heat exchange capacity, applied in lighting and heating equipment, steam/steam condensers, etc., can solve the problems of adverse effects of steam turbine operation, increase of steam turbine back pressure, reduction of power generation efficiency, etc., to improve heat exchange capacity. , The effect of reducing back pressure and increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

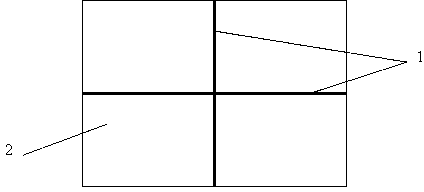

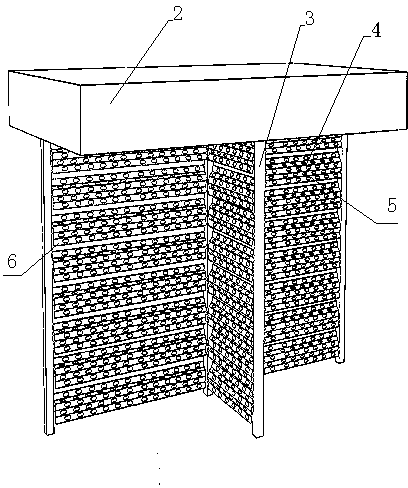

[0021] A windproof device 1 for improving the heat dissipation efficiency of a direct air cooling system, comprising a support frame 3, a base of the support frame 3, a wind barrier blade 4 installed on the support frame 3, and a wind barrier blade opening system.

[0022] The wind barrier blade 4 is provided with an air guide hole 5, and the opening rate of the air guide hole 5 on the wind barrier blade 4 is 20%-60%.

[0023] The wind barrier blade opening system is composed of an anemometer, a thermometer, a computer-controlled instrument and an opening device. The anemometer and the thermometer are connected to the computer-controlled instrument, and the computer-controlled instrument is connected to the motor of the opening device.

[0024] After the wind speed, wind direction angle and other data are obtained through the anemometer and the thermometer, they are transmitted to the computer controller, and the control system calculates and sends instructions to the opening d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com