Large-dimension hexagonal bi-layer grapheme single-crystal domain and preparation method thereof

A double-layer graphene and hexagonal technology, applied in the field of nanomaterials, can solve the problems that affect the transportation properties of graphene, the number of layers cannot be adjusted, and it is limited to the range of hundreds of nanometers to tens of microns, and is suitable for large-scale Easy control of production and process, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

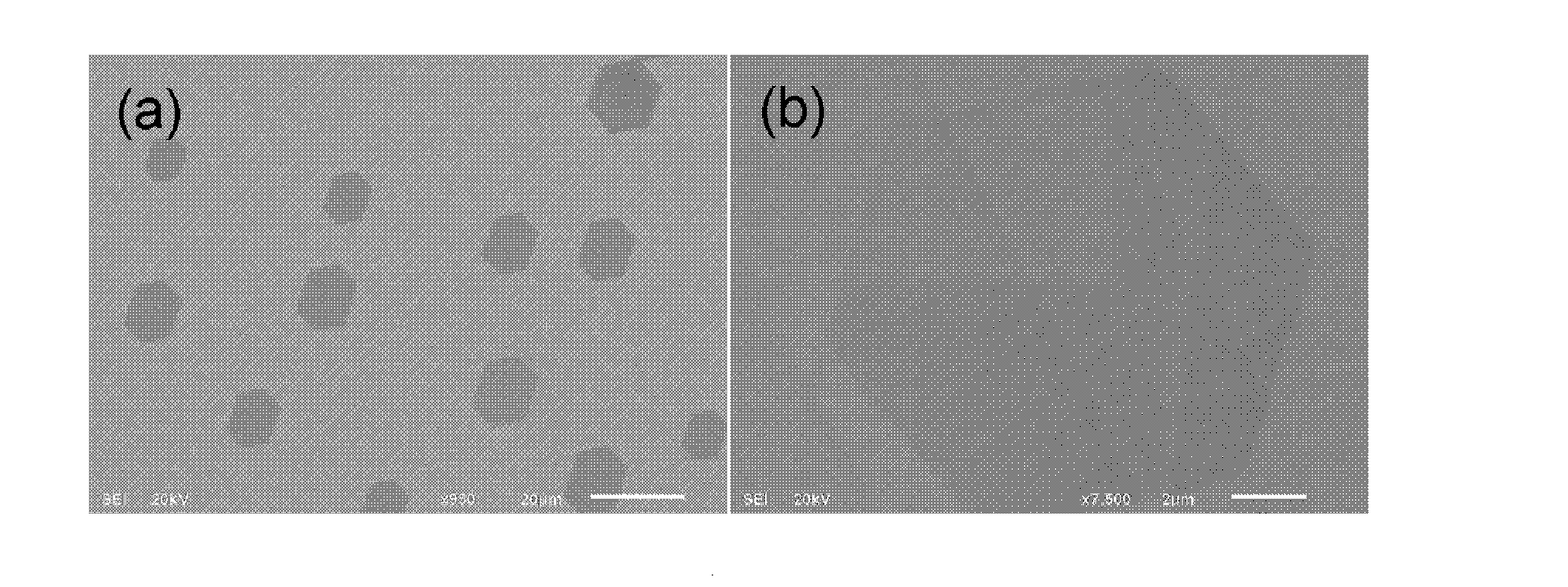

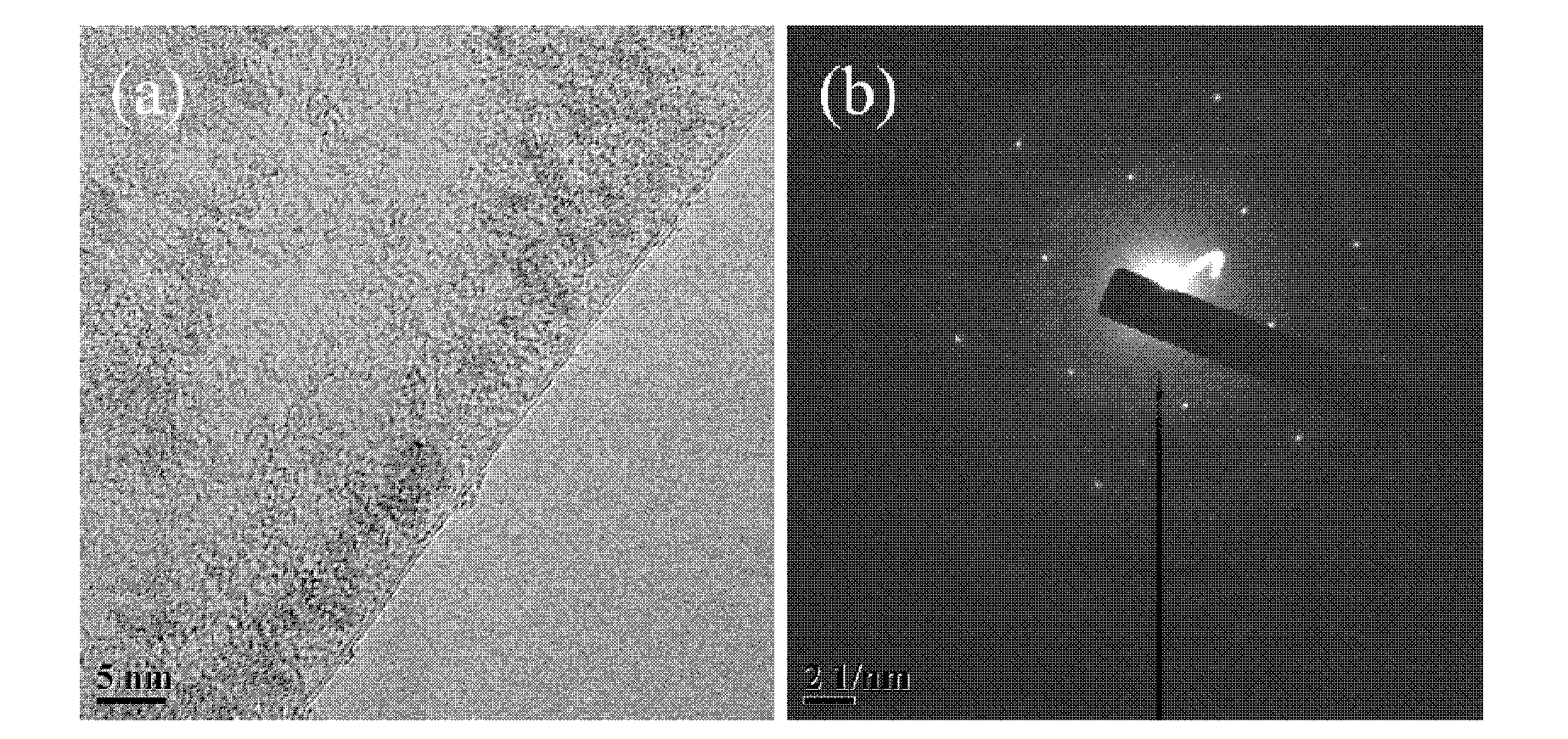

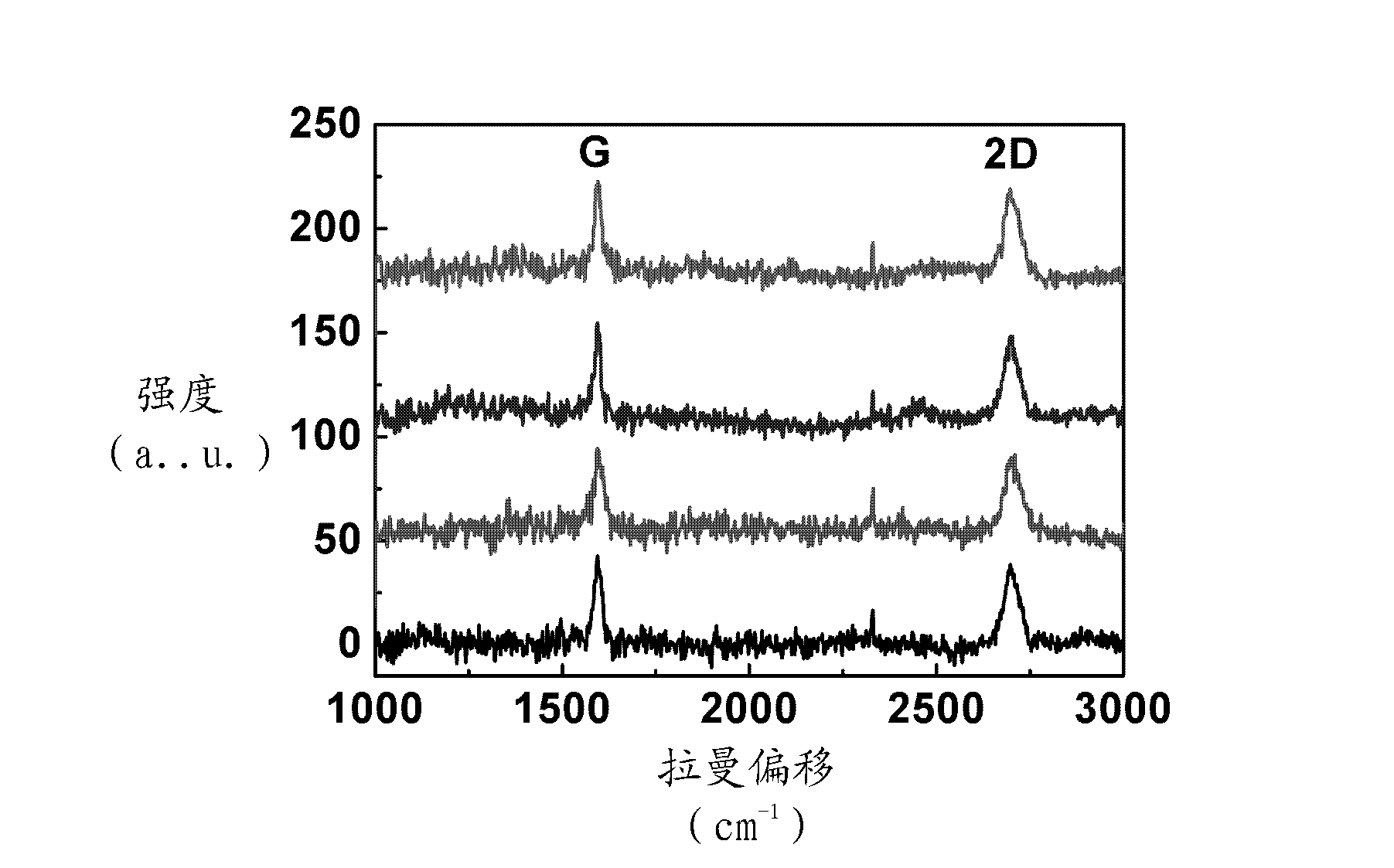

[0019] (1) Use 25 μm copper foil (purchased from Alfa (alfa) company, product number 13382) as a catalyst, put it into a chemical vapor deposition reaction furnace, feed 300 sccm hydrogen and 300 sccm argon, and start heating to 1000 ° C after 60 minutes, After constant temperature for 30 minutes, 20sccm methane, 200sccm hydrogen, 100sccm argon are introduced, and the reaction time is 20 minutes. After the reaction, stop passing methane, turn off the electric furnace, and rapidly cool to room temperature to obtain hexagonal graphene single crystal domains. Electron microscope photos such as figure 1 shown. Graphene is a double-layer structure, TEM photos and Raman spectra are as follows figure 2 The bilayer coverage shown is 93%.

Embodiment 2

[0021] The preparation method is basically the same as in Example 1, the difference being that a 600nm metal nickel film is deposited on a 25 μm Cu foil substrate by magnetron sputtering, and this binary alloy is used as a catalyst, and 200 sccm of hydrogen gas is introduced, and after 60 minutes Start heating to 1040°C, keep the temperature for 30 minutes, and then feed 2 sccm acetylene and 200 sccm hydrogen, and the reaction time is 60 minutes. Obtain graphene single crystal domains as bilayer structure ( figure 2 ), the graphene size is 40–80 μm, and the bilayer coverage is 95%.

Embodiment 3

[0023] The preparation method is basically the same as in Example 1, the difference is: adopt copper-nickel alloy (Cu0.7Ni0.3) as the catalyst, feed 800 sccm hydrogen, start heating to 1040 ° C after 60 minutes, and feed 10 sccm nitrogen drum after 30 minutes at constant temperature Soak ethanol, 400s ccm hydrogen, and the reaction time is 5 hours. The obtained graphene single crystal domain is a bilayer structure, the graphene size is 100 μm, and the bilayer coverage is 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com