Self-heating thermal fabric

A self-heating and fabric technology, applied in the field of fabrics, can solve the problems of uncomfortable clothing and inability to emit heat spontaneously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

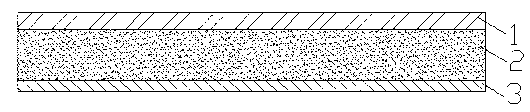

[0013] Described in the present invention is a kind of self-heating warm-keeping fabric, see figure 1 As shown, the upper windproof layer 1, the heating layer 2 below the windproof layer 1, and the personal comfort layer 3 below the heating layer 2, the windproof layer 1 is made of 120 counts of spandex fibers and 160 counts of flax fibers. , the heating layer 2 is woven from nylon fibers wrapped with high-purity iron powder and catalyst, and the personal comfort layer 3 is woven from polyester-silk blended fibers.

[0014] Further, the weight percentages of spandex fibers and flax fibers in the windproof layer 1 are 61% and 39% respectively.

[0015] Further, the thickness of the windproof lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com