Internal gear grinding machine, gear grinding machine, measuring sensor support and linear guide piece

A technology for measuring sensors and gear grinding, which is applied to gear tooth manufacturing devices, gear cutting machines, components with teeth, etc., and can solve problems such as inability to maintain workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

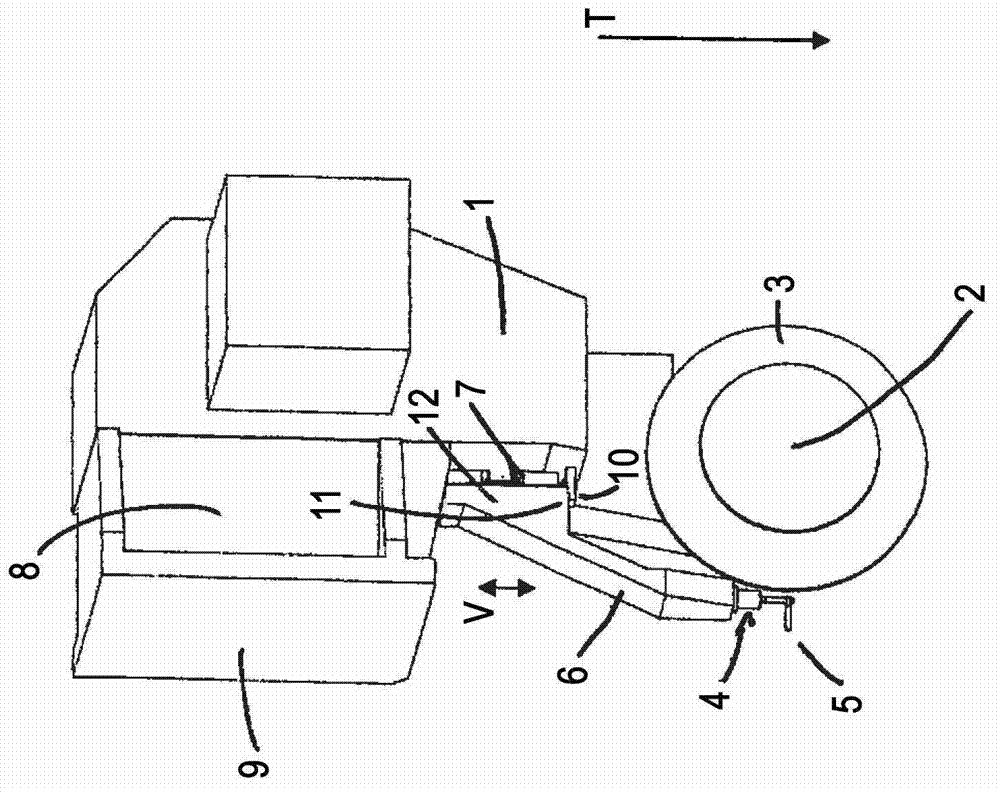

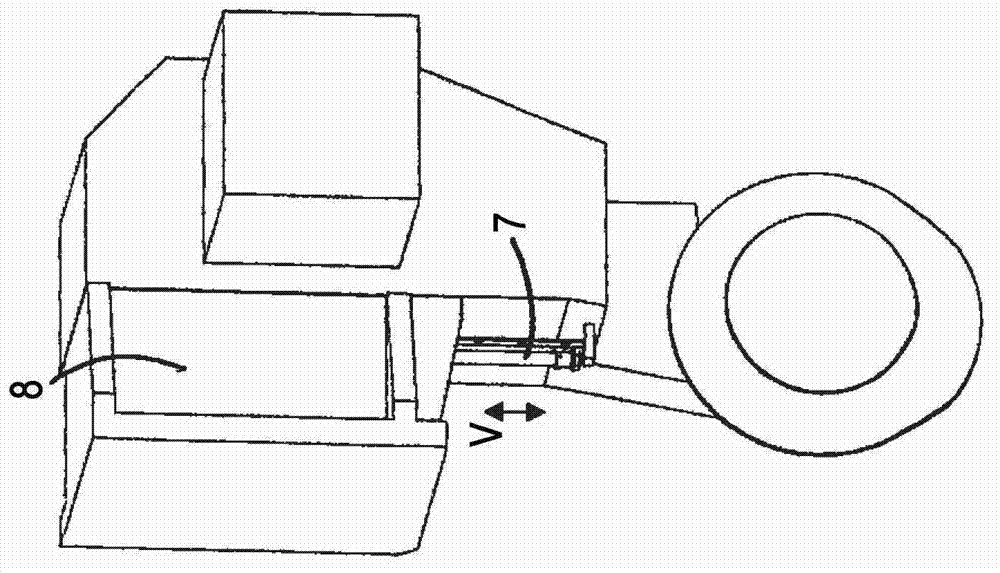

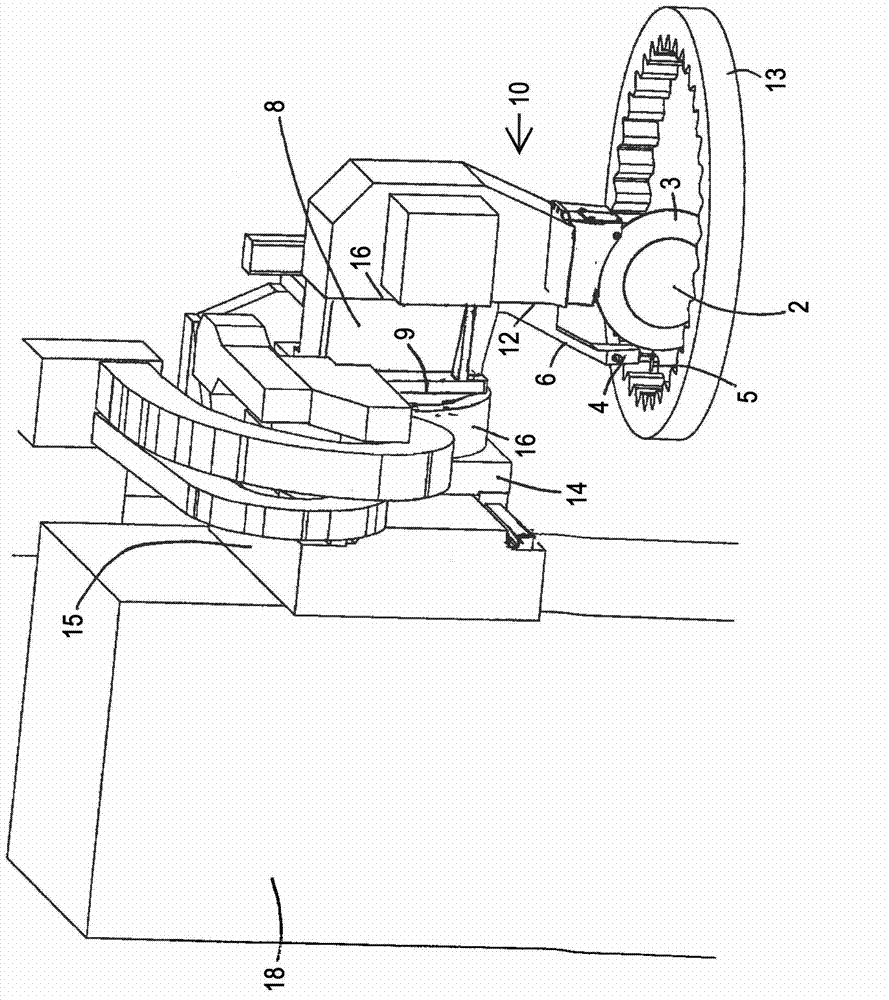

[0054] will now refer to figure 1 with 2 Embodiments of the present invention are described in more detail. In this respect, the internal gear grinding machine according to the invention has a grinding arm 1 at the lower end of which is arranged a grinding wheel spindle 2 on which a grinding wheel 3 is arranged. In this regard, in this embodiment no further accessories are arranged below the grinding wheel spindle, so that no construction space is wasted towards the bottom.

[0055] In this respect, the measuring head 4 has a measuring sensor which is triggered by a movement of the measuring sensor element 5 . In this respect, the measuring sensor element 5 extends away from the measuring head towards the front end in the joining direction.

[0056] In this respect, the centering of the grinding wheel or the screwing of the grinding wheel to the workpiece denticulations and / or the measurement of the denticulations can be performed by the measuring head according to the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com