Flotation separation method of antimony sulfide gold minerals

A technology of mineral flotation and separation method, applied in flotation, solid separation and other directions, can solve the problems of difficult separation, affecting gold recovery rate, waste of resources, etc., to achieve the effect of less energy consumption, less chemical dosage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Mineral raw materials:

[0016] The antimony content in the mineral raw materials used is 0.37%, and the gold content is 1.86 g / t. Phase analysis shows that the antimony-containing minerals are mainly stibnite, and the gold-bearing minerals are pyrite and arsenopyrite.

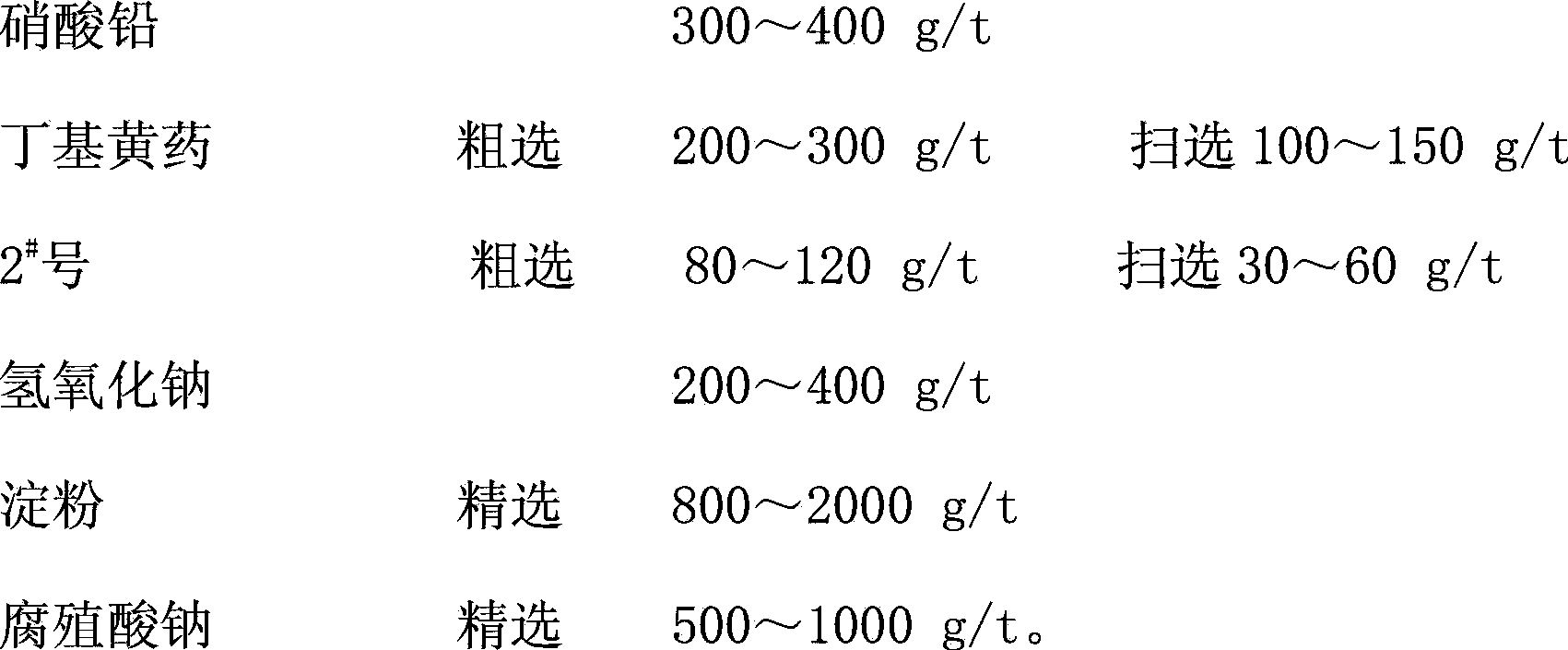

[0017] 2. The total dosage of flotation agents is:

[0018]

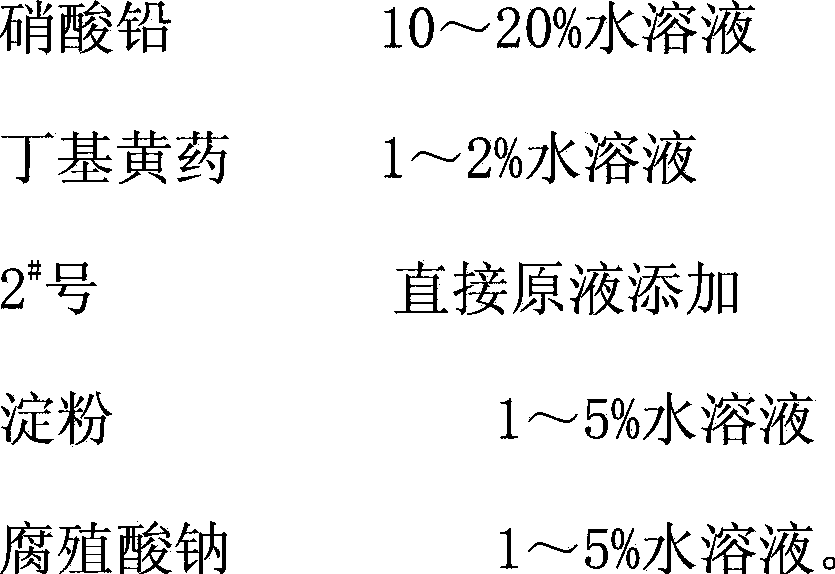

[0019] The operation steps and technical conditions are as follows:

[0020] In the process of mixed flotation, the ore is added to the ore mill to grind the ore until the mineral monomer is dissociated. Under natural pH conditions, lead nitrate is firstly added as the activator of antimony gold minerals, and then butyl xanthate is added for collection. agent, and finally add 2 # No. 1 oil was used as a foaming agent for mixed flotation to obtain mixed antimony-gold concentrate; in the flotation separation process, active carbon was used to remove the drug, and then sodium hydroxide was used to adjust the pH value to 8.5, and then sod...

Embodiment 2

[0022] 1. Mineral raw materials:

[0023] The antimony content in the mineral raw materials used is 0.62%, and the gold content is 2.15 g / t. Phase analysis shows that the antimony-containing minerals are mainly stibnite, and the gold-bearing minerals are pyrite and arsenopyrite.

[0024] 2. The total dosage of flotation agents is:

[0025]

[0026] The operation steps and technical conditions are as follows:

[0027] In the process of mixed flotation, the ore is added to the ore mill to grind the ore until the mineral monomer is dissociated. Under natural pH conditions, lead nitrate is firstly added as the activator of antimony gold minerals, and then butyl xanthate is added for collection. agent, and finally add 2 # No. oil is used as a foaming agent for mixed flotation to obtain mixed antimony-gold concentrate; in the flotation separation process, activated carbon is used to remove the drug, and then sodium hydroxide is used to adjust the pH value to 9, and then sodium ...

Embodiment 3

[0029] 1. Mineral raw materials:

[0030] The antimony content in the mineral raw materials used is 0.87%, and the gold content is 3.26 g / t. Phase analysis shows that the antimony-containing minerals are mainly stibnite, and the gold-bearing minerals are pyrite and arsenopyrite.

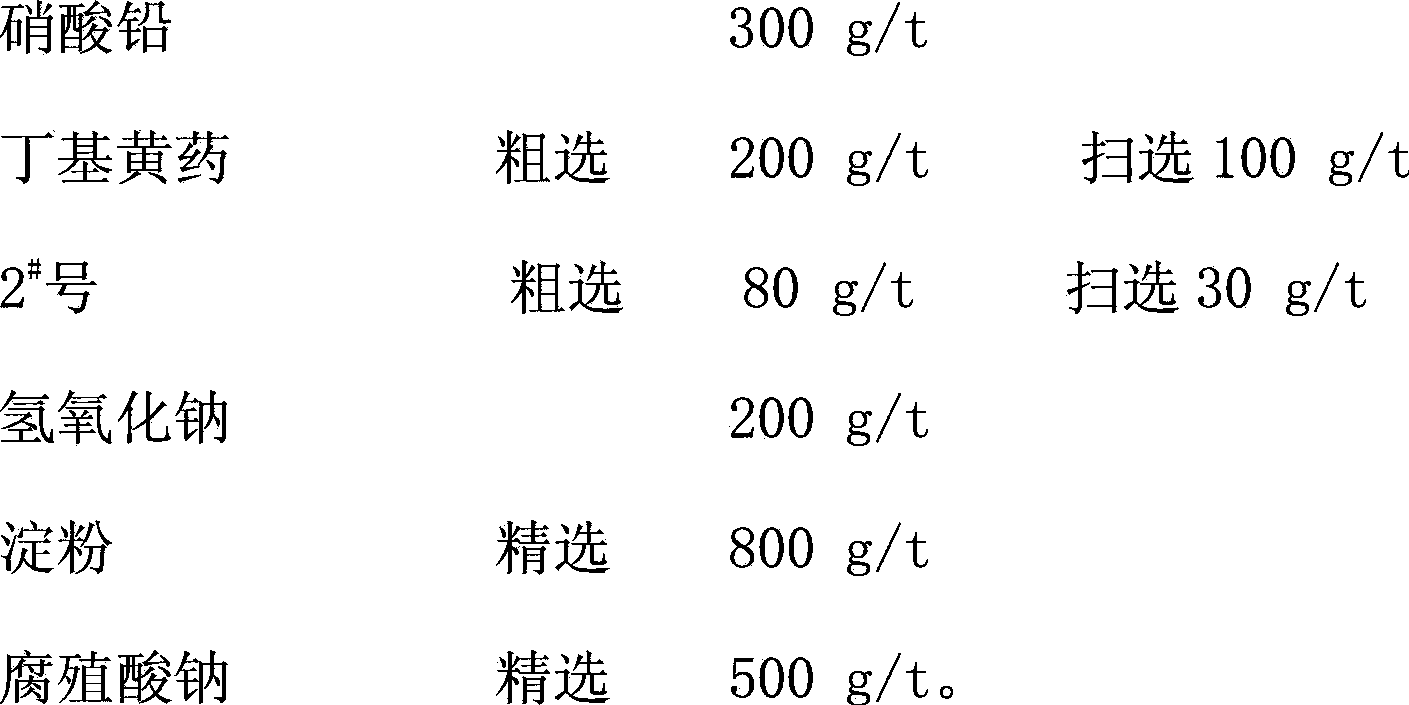

[0031] 2. The total dosage of flotation agents is:

[0032]

[0033] The operation steps and technical conditions are as follows:

[0034] In the process of mixed flotation, the ore is added to the ore mill to grind the ore until the mineral monomer is dissociated. Under natural pH conditions, lead nitrate is firstly added as the activator of antimony gold minerals, and then butyl xanthate is added for collection. agent, and finally add 2 # No. oil is used as a foaming agent for mixed flotation to obtain mixed antimony-gold concentrate; in the flotation separation process, active carbon is used to remove the drug, and then sodium hydroxide is used to adjust the pH value to 9.5, and then sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com