Return control system

A technology of recovery control and urea water, which is applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of poor action of quantitative valve 104, no recovery control, and uncertain pressure, and achieves the effect of eliminating poor action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described below with reference to the drawings.

[0031] First, an SCR system mounted on a vehicle will be described.

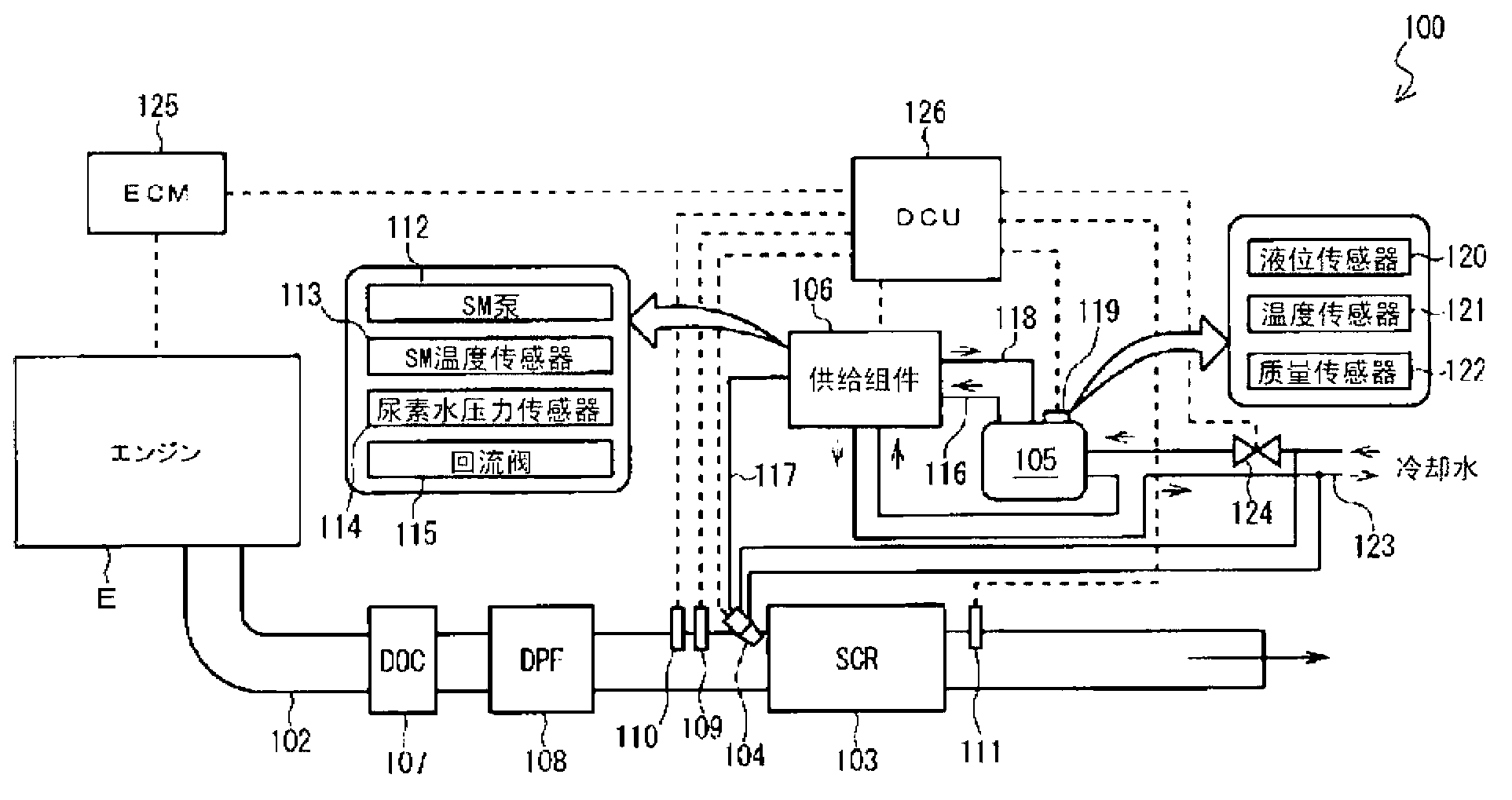

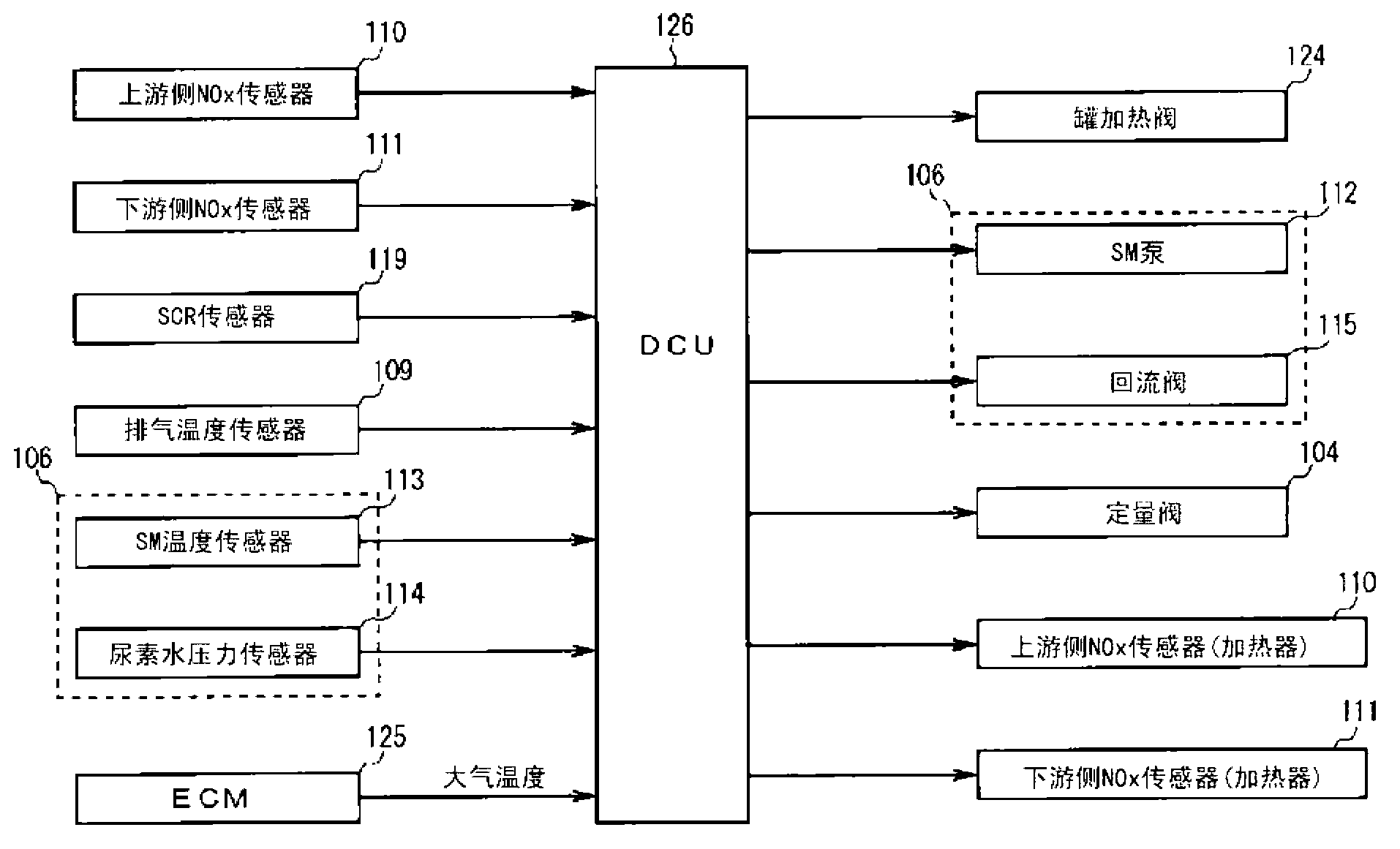

[0032] like figure 1 As shown, the SCR system 100 mainly includes: an SCR device 103 arranged in the exhaust pipe 102 of the engine E, a metering valve (urea injection device, metering assembly) for injecting urea water on the upstream side of the SCR device 103 (the upstream side of the exhaust gas) ) 104, a urea tank 105 for storing urea water, a supply assembly 106 for supplying the urea water stored in the urea tank 105 to the dosing valve 104, a DCU (Dosing Control Unit) 126 for controlling the dosing valve 104 or the supply assembly 106, etc.

[0033] In the exhaust pipe 102 of the engine E, a DOC (Diesel Oxidation Catalyst) 107 , a DPF (Diesel Particulate Filter) 108 , and an SCR device 103 are arranged sequentially from the upstream side of the exhaust gas to the downstream side. DOC107 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com