Low-consumption loss transformer

A transformer, low-loss technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, metal/alloy conductor, etc., can solve the problem of unreasonable mechanical performance and electrical design, energy saving, stable performance The performance is not ideal and the no-load loss of the transformer is large, so as to achieve the effect of small footprint, long service life and high operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

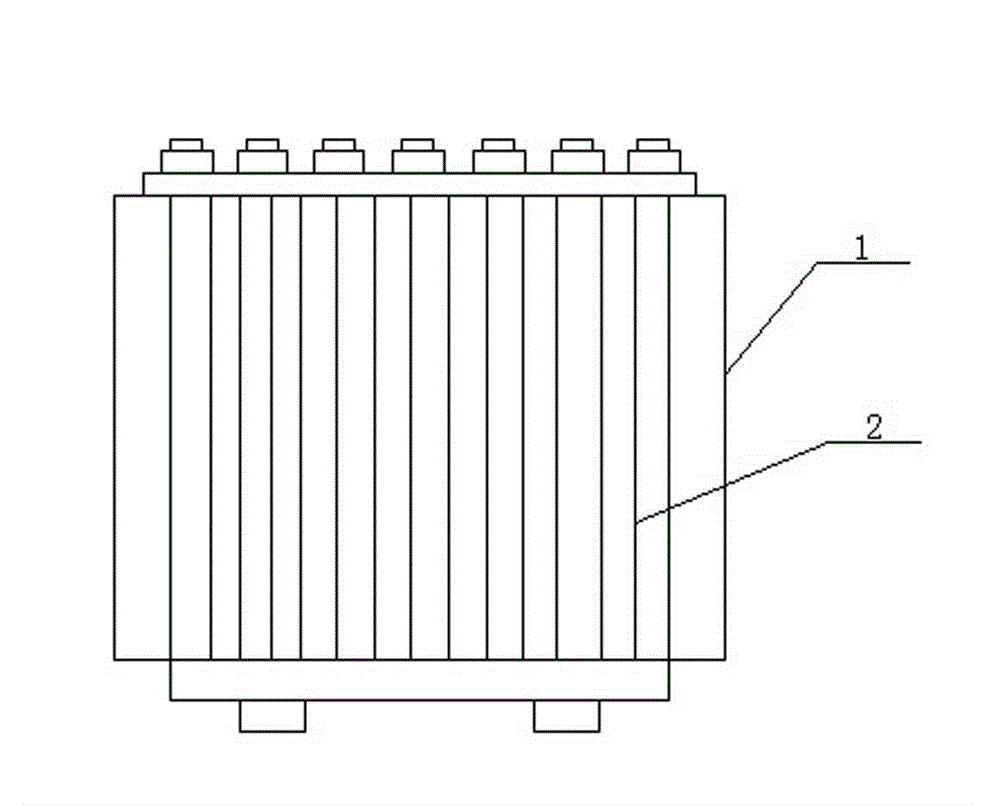

[0012] Such as figure 1 As shown, a low-loss transformer according to the present invention includes a casing 1, an oil tank 2, an iron core and a coil, and the iron core and coil are assembled into a device through body insulation and lead wires and placed in the oil tank 2 behind, The winding on the iron core is a copper winding, and the copper winding is an alloy copper. The formula of the alloy copper includes silver, silicon, and nickel, and the weight percentage content of each component is: silver: 1.5%, silicon: 0.01% , Nickel: 0.01%, and the balance is copper. Using the above materials, the no-load and load losses can be significantly reduced, and it has been proved by experiments that the present invention reduces the no-load loss by an average of 10.25% and the no-load current by 37.9% compared with GB / T6451 %, and the operating cost is reduced by an average of 18.9%, so it has the characteristics of energy saving. Wherein, the oil tank 2 adopts a fully sealed stru...

Embodiment 2

[0015] Such as figure 1 As shown, a low-loss transformer according to the present invention includes a casing 1, an oil tank 2, an iron core and a coil, and the iron core and coil are assembled into a device through body insulation and lead wires and placed in the oil tank 2 behind, The winding on the iron core is a copper winding, and the copper winding is an alloy copper. The formula of the alloy copper includes silver, silicon, and nickel, and the weight percentage content of each component is: silver: 2.2%, silicon: 0.35% , Nickel: 0.05%, the balance is copper.

[0016] The fuel tank 2 adopts a fully sealed structure.

[0017] The oil tank 2 is a corrugated plate radiator.

[0018] The oil tank 2 is fixedly connected to the casing 1 through bolt connection or welding.

Embodiment 3

[0020] Such as figure 1 As shown, a low-loss transformer according to the present invention includes a casing 1, an oil tank 2, an iron core and a coil, and the iron core and coil are assembled into a device through body insulation and lead wires and placed in the oil tank 2 behind, The winding on the iron core is a copper winding, and the copper winding is an alloy copper. The formula of the alloy copper includes silver, silicon, and nickel, and the weight percentage content of each component is: silver: 3.0%, silicon: 0.5% , Nickel: 0.1%, the balance is copper.

[0021] The fuel tank 2 adopts a fully sealed structure.

[0022] The oil tank 2 is a corrugated plate radiator.

[0023] The oil tank 2 is fixedly connected to the casing 1 through bolt connection or welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com