Super wear-resistant and temperature-resistant light endless conveyor belt

A technology of endless conveyor belts and conveyor belts, applied in conveyors, transportation and packaging, etc., can solve the problems of poor high resistance, high driving power, short service life, etc., achieve ultra-high strength and wear resistance, save raw materials, The effect of reducing no-load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

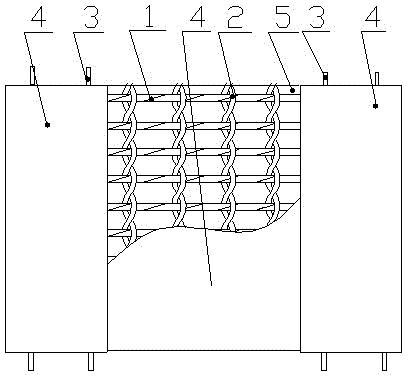

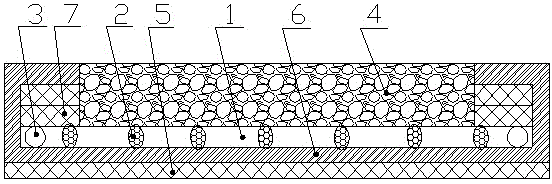

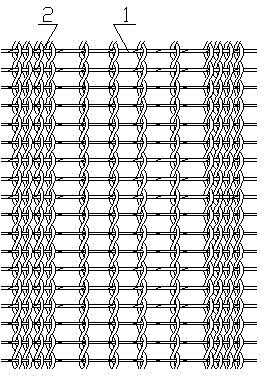

[0016] Embodiment 1: with reference to attached figure 1 with 2 . A super-abrasion-resistant and temperature-resistant light endless conveyor belt, including an endless conveyor belt. The skeleton in the endless conveyor belt is made of multiple steel wires 1 as weft ribs and multiple fibers 2 as warp threads. Multiple steel wires are made of multiple fibers. 2 Woven into a curtain-shaped conveyor belt skeleton, the two longitudinal sides of the curtain-shaped conveyor skeleton are respectively equipped with one or more steel wires 3 or one or more steel wires 3 and strong canvas 7 to form a tensile curtain conveyor belt skeleton (such as figure 2 As shown), the strong canvas 7 has a multi-layer laminated structure and is covered by a rubber layer; the working surface of the tensile curtain conveyor belt skeleton is provided with a rubber layer 4, and the non-working surface is bonded with a strong fiber cloth 5 through the rubber layer 6. The said fiber 2 refers to aramid ...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, the density between the fiber warps and the fiber warps at the two longitudinal sides of the curtain-shaped conveyor belt skeleton is greater than the density in the middle of the curtain conveyor belt skeleton.

Embodiment 3

[0018] Embodiment 3: On the basis of Embodiment 1, the diameters of the fiber warps located at the two longitudinal sides of the curtain-shaped conveyor belt skeleton are greater than the diameter of the fiber warps in the middle of the curtain conveyor belt skeleton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com