Conveyor belt control device

A conveyor belt and control device technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as interference, large starting current, and large impact on the conveyor belt to achieve small impact and reduce Shock, the effect of reducing the starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

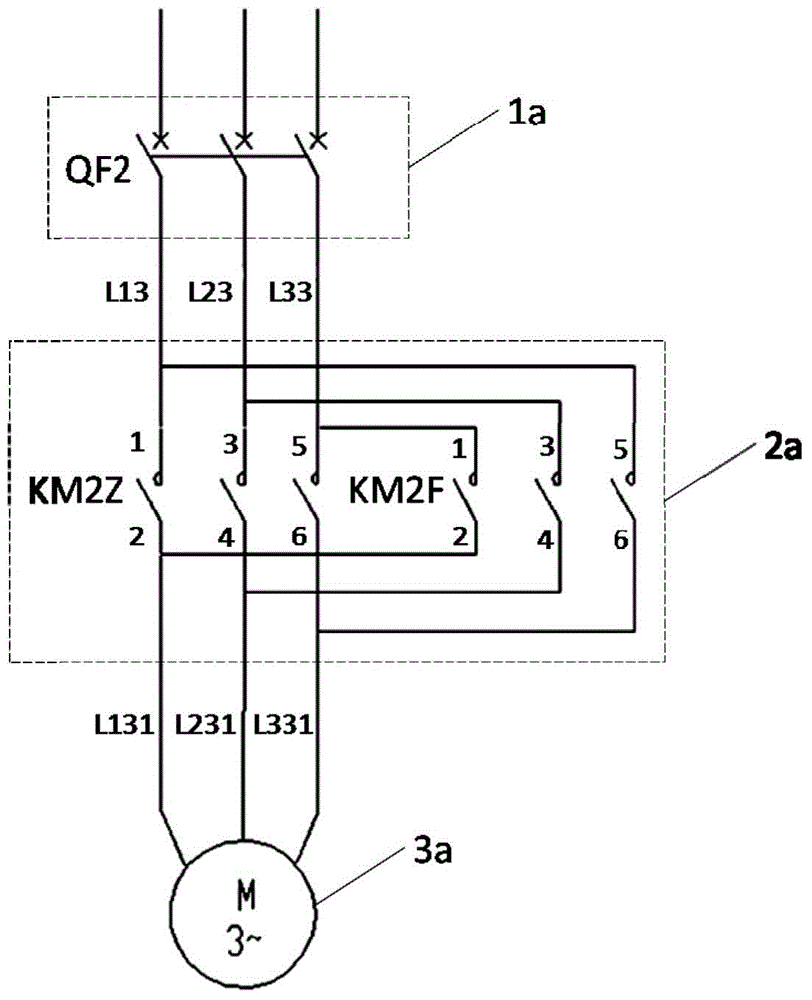

[0023] In the prior art, the motor-driven conveying belt movement generally adopts direct start. The circuit breaker 1a controls the connection or disconnection of the three-phase power supply. The contactor 2a controls the forward and reverse rotation of the motor 3a, and then directly connects with the three-phase motor 3a. Connection, this kind of control method has a large starting current at no-load and on-load, which interferes with other electrical equipment in the grid, and causes a large impact when the belt starts and stops. Therefore, a step-down starting device needs to be added to the control system to reduce the starting current, which will be described in detail below.

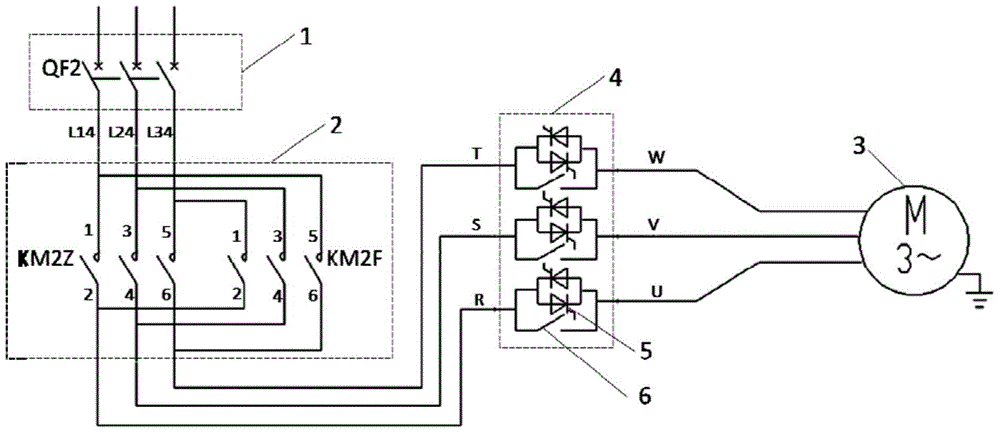

[0024] The invention provides a conveyor belt control device, such as image 3 As shown, it includes: the circuit breaker 1 and the contactor 2 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com