Method for producing copper clad aluminum pipe and used production line

A production method, copper-clad aluminum technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as process difficulty, and achieve the effect of reducing load, reducing weight, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

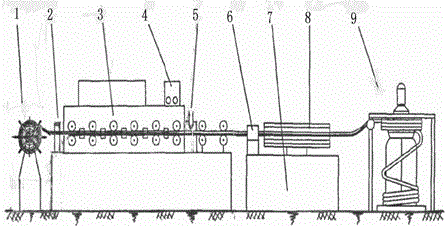

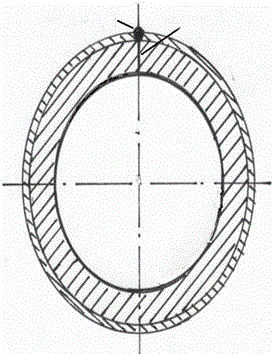

[0024] Taking the copper-aluminum composite board with a copper layer thickness of 0.2mm and an aluminum layer thickness of 0.46mm as an example, it is explained in figure 1 The method for producing copper-clad aluminum tubes with an outer diameter of φ13.1mm on the production line shown.

[0025] 1. Prepare copper-aluminum composite strip: In order to obtain a copper-clad aluminum tube with an outer diameter of φ13.1mm after the clad and welded copper-clad aluminum tube billet is drawn with a section reduction rate of about 25%, the cutting When cutting the width of the copper-aluminum composite strip, it should be calculated according to φ15.1mm. The blanking width is 47.4mm.

[0026] 2. The cut copper-aluminum composite strip is placed on the tray 1 with the aluminum layer facing up and the copper layer facing down.

[0027] 3. When the copper-aluminum composite strip passes through the groove cutting device 2, after the two ends of the aluminum layer are cut out of the 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com