Aluminium electrolysis cell with insulation structure

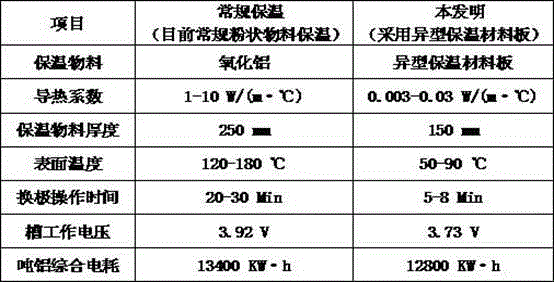

An aluminum electrolytic cell and electrolyte technology, applied in the field of aluminum electrolytic cells, can solve the problems of less than 50% electric energy utilization rate, affecting the stable operation of the electrolytic cell, and increasing the workload of pole changing, so as to improve the working efficiency of pole changing and avoid work Instability, the effect of reducing the working voltage of the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

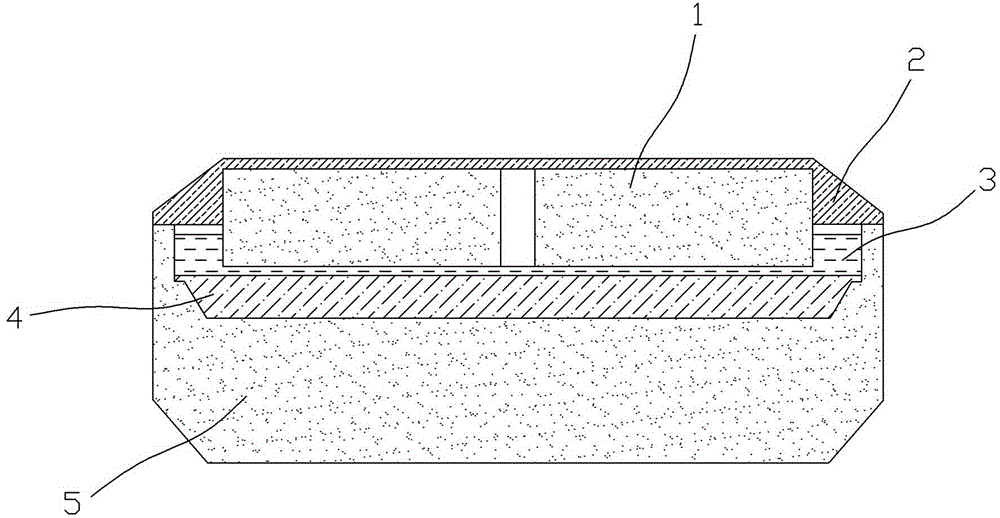

[0018] Embodiment 1: a kind of aluminum electrolytic cell of tool insulation structure, see figure 1 , an aluminum electrolytic cell with a thermal insulation structure, comprising a cell body filled with electrolyte and an anode carbon block 1, and a layer capable of simultaneously matching the upper edge of the cell body, the electrolyte and the anode carbon block is installed above the cell body The special-shaped sealed heat-insulation board 2 is made of high-temperature-resistant and light-weight alumina material. A high temperature resistant anti-oxidation coating is provided on the surface of the anode carbon block.

[0019] The preparation of the above-mentioned special-shaped insulation material board:

[0020] Raw material composition: alumina 60~99%, SiO 2 Content 0.5-40%, CaO 0.1-0.5%, MgO 0.1-0.5%; mix the above raw materials in proportion, add binder (hydrogen peroxide) and make pulp (slurry concentration: solid content 450g / L), and then shape , drying and oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com