Novel CO isothermal conversion method

A new type of isothermal transformation technology, applied in the field of temperature transformation, can solve the problems of safe operation of equipment affecting the service life of catalyst, high hot spot temperature of catalyst bed, easy occurrence of methanation reaction, etc. Side reactions, effect of constant operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

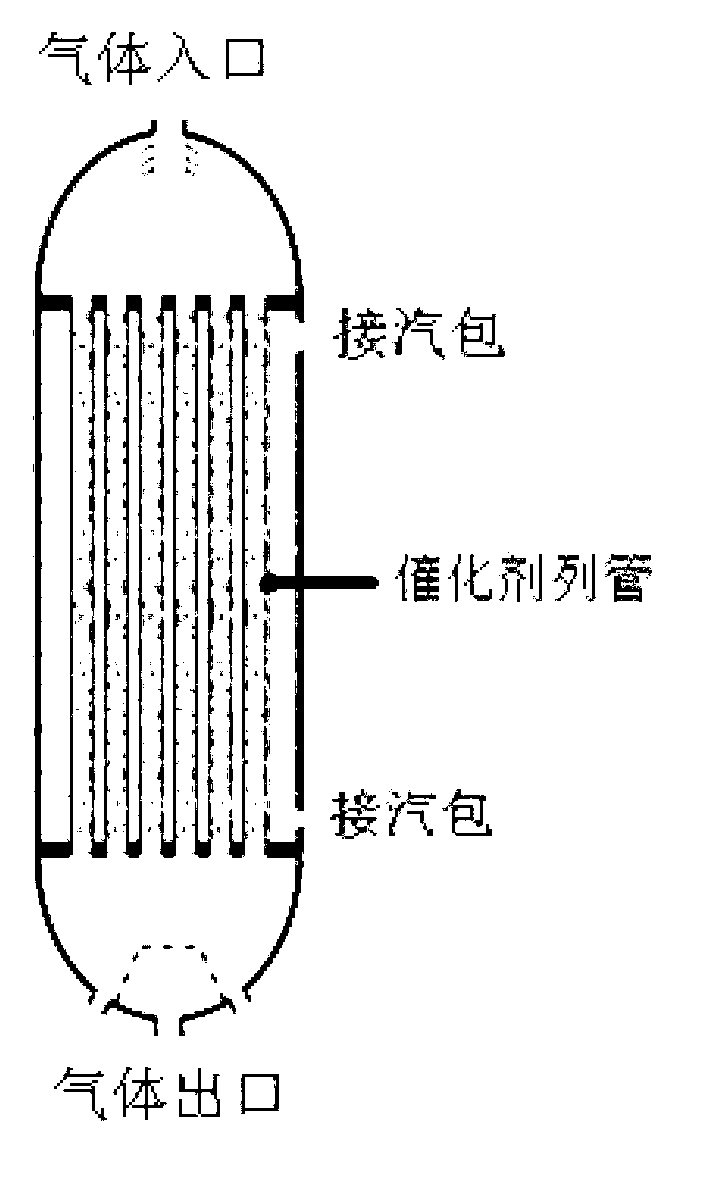

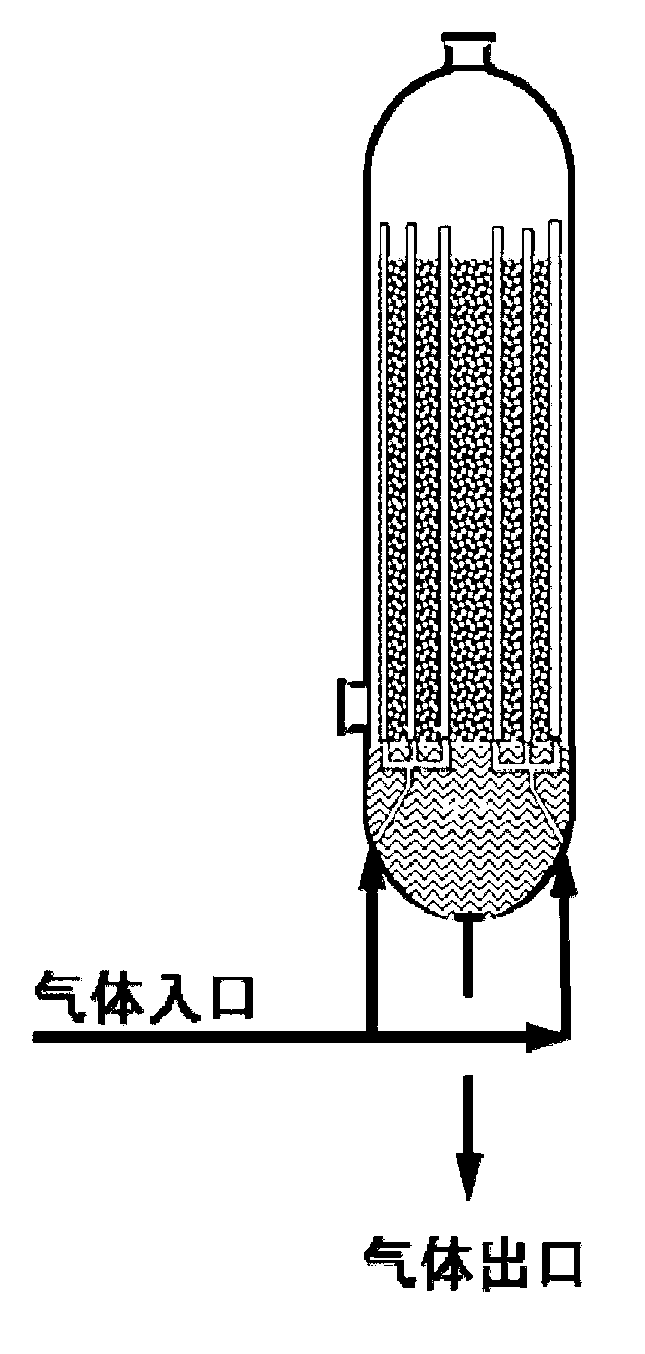

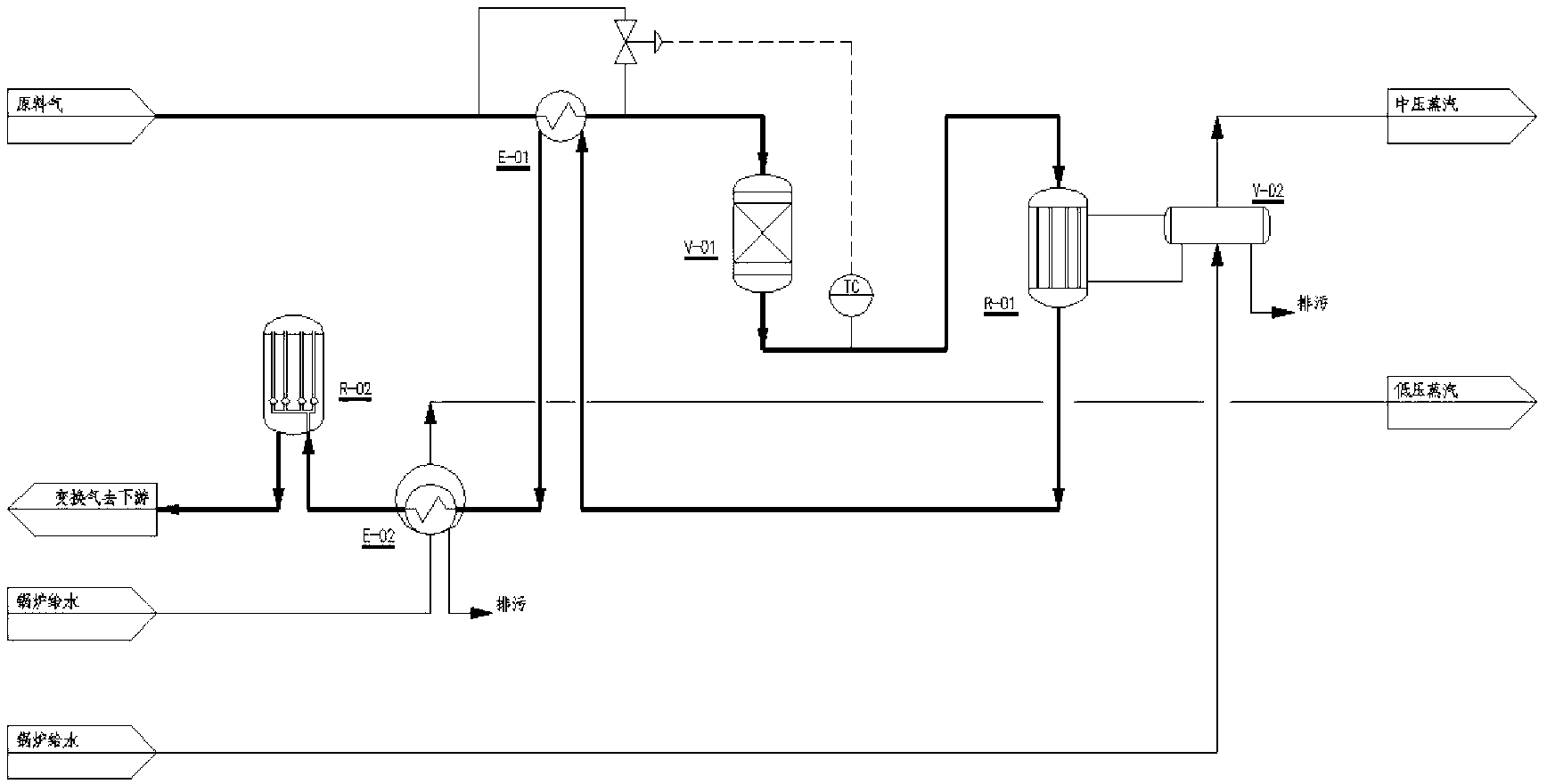

Embodiment 1

[0036] The raw material gas is calcium carbide furnace gas. After dedusting and compression, the temperature is 140°C and the pressure is 3.0MPaG. The raw material gas is filled with steam and then enters the transformation process. The raw gas is heated by the raw gas preheater to 230°C, and enters the raw gas filter to filter dust and remove poisons. The filtered raw gas enters the first shift furnace (axial flow steam reactor) for shift reaction. The coal gas goes through the tube side of the first converter, and the shell side tube passes through the boiler feed water to by-produce steam to take off the reaction heat. After leaving the first shift furnace, the gas enters the raw gas preheater to preheat the inlet raw gas, then enters the waste heat boiler by-product steam to cool down, and then enters the second shift furnace (air-cooled reactor) for shift reaction. The heat of reaction generated in the second shift furnace is removed by preheating the inlet gas of the se...

Embodiment 2

[0040] The raw material gas is water gas produced by GSP gasification technology (dry pulverized coal fluidized bed gasification technology). After liquid and dust removal, the temperature is 209°C and the pressure is 3.8MPaG to enter the transformation process. The raw gas is heated by the raw gas preheater to 230°C, and enters the raw gas filter to filter dust and remove poisons. The filtered raw gas enters the first shift furnace (axial flow steam reactor) for shift reaction. The coal gas goes through the tube side of the first converter, and the shell side tube passes through the boiler feed water to by-produce steam to take off the reaction heat. After the gas leaves the first shift furnace, it enters the raw gas preheater to preheat the inlet raw gas, and then enters the waste heat boiler by-product steam to cool down, and then enters the second shift furnace (air-cooled reactor) for shift reaction. The heat of reaction generated in the second shift furnace is removed b...

Embodiment 3

[0044] The raw material gas is water gas produced by coal-water slurry gasification technology. After liquid and dust removal, the temperature is 221°C and the pressure is 40.6MPaG to enter the conversion process. The raw gas is heated by the raw gas preheater to 270°C, and enters the raw gas filter to filter dust and remove poisons. The filtered raw gas enters the first shift furnace (axial steam reactor) for shift reaction. The coal gas goes through the tube side of the first converter, and the shell side tube passes through the boiler feed water to by-produce steam to take off the reaction heat. After the gas leaves the first shift furnace, it enters the raw gas preheater to preheat the inlet raw gas, and then enters the waste heat boiler by-product steam to cool down, and then enters the second shift furnace (air-cooled reactor) for shift reaction. The heat of reaction generated in the second shift furnace is removed by preheating the inlet gas of the second shift furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com