A kind of dense medium dry separation equipment

A sorting and dry method, applied in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, etc., can solve the problems of worsening sorting effect, destroying sorting effect, and uneven feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below according to the accompanying drawings:

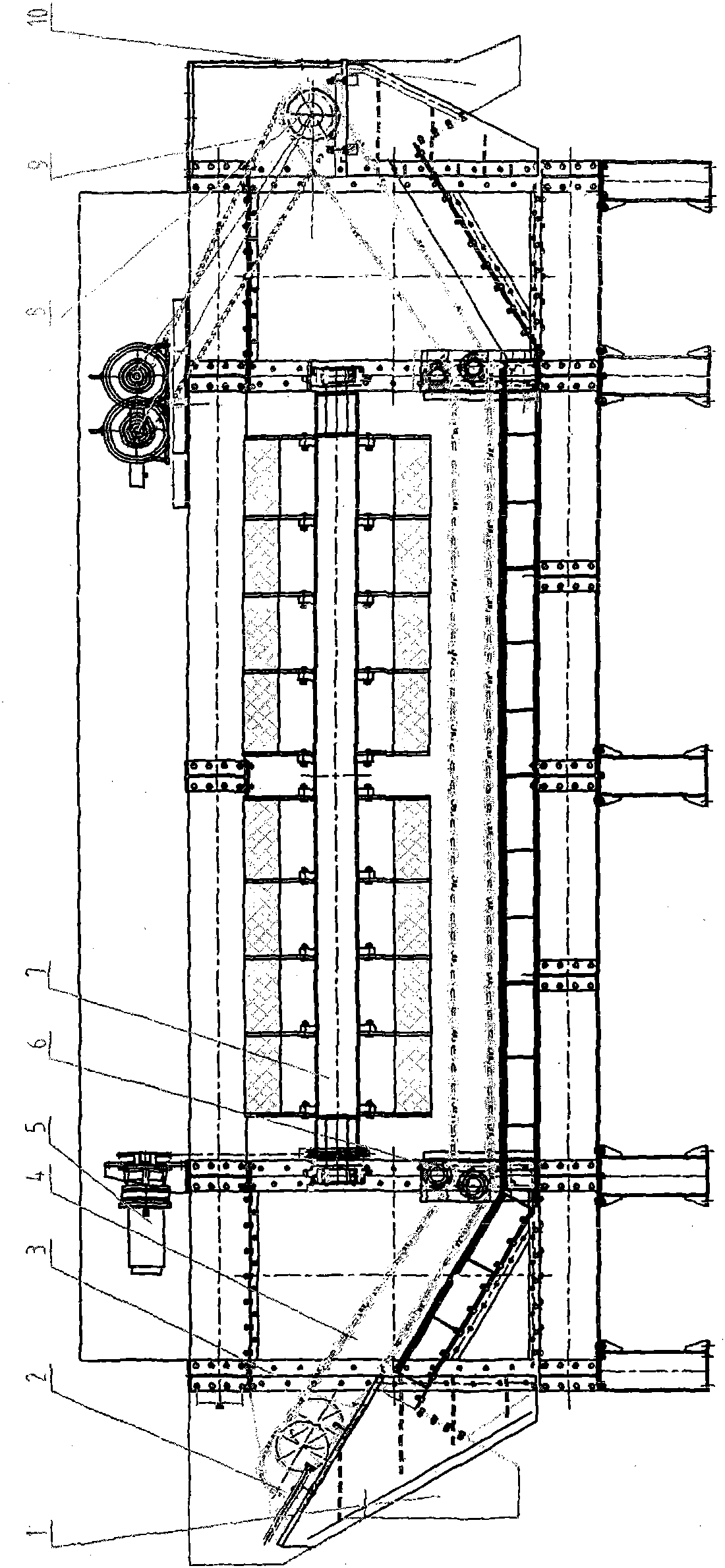

[0019] in the attached figure 1 Middle: medium coal discharge chute 1; large scraper conveying device tail 2; box 3, used to provide space for forming a sorting fluidized bed and installing various devices; sieve plate 4 under the upper scraper of the tail, used Screening and recovery of media; motor 5; pressing sprocket 6; reclaiming and screening device rotating shaft 7; sprocket 8; chain 9; gangue discharge chute 10;

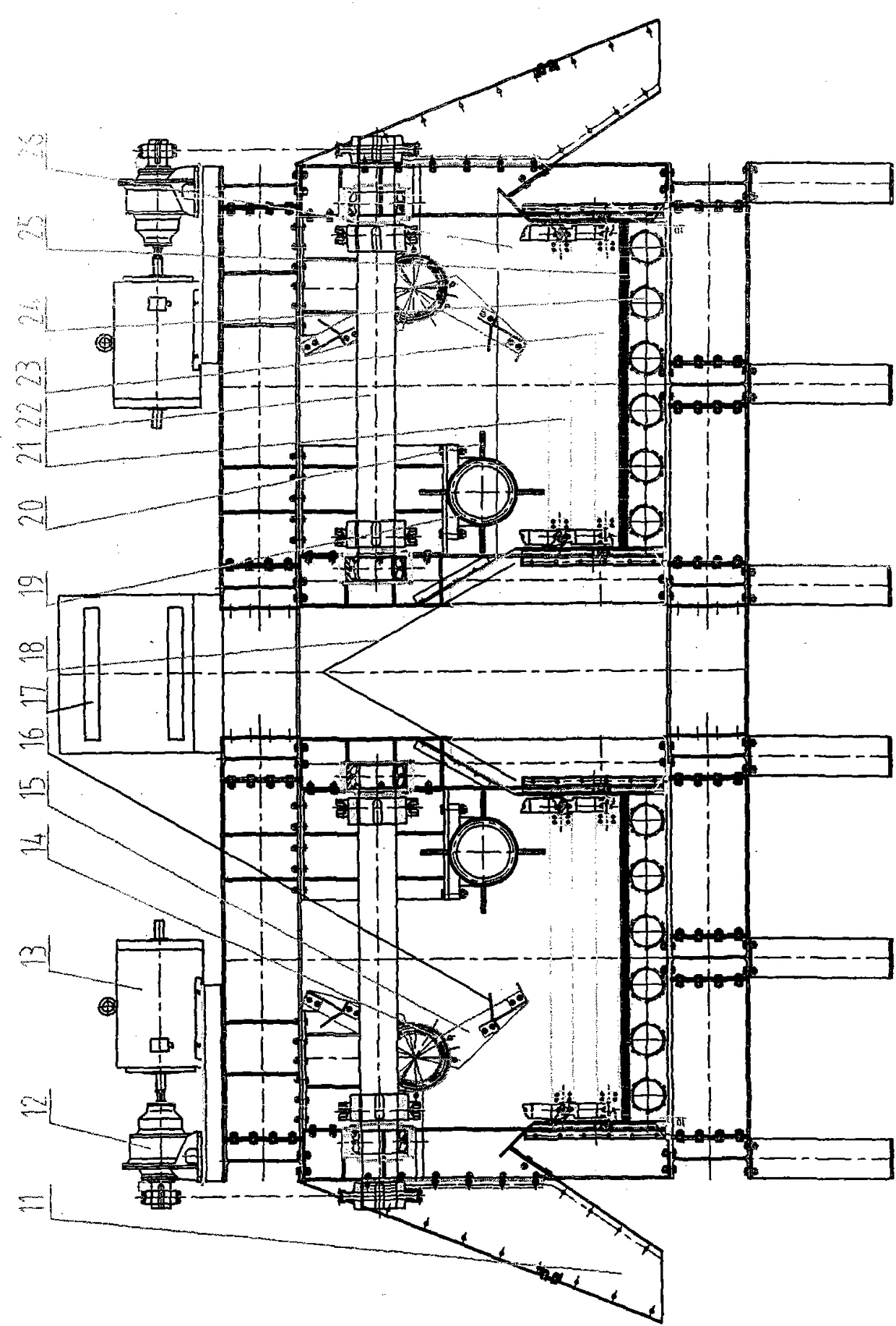

[0020] in the attached figure 2 Middle: clean coal discharge chute 11; planetary gear reducer 12; motor 13; clean coal retrieving and screening device 14 (see attached Figure 6 ), the clean coal retrieving and screening device will take out the clean coal, and the clean coal will sieve out the heavy medium and return to the fluidized bed during the retrieving movement of the sieve basket; the sieve basket support frame 15; the sieve basket 16, which is imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com