Graphene-reinforced nickel-based composite coating material and laser cladding technology thereof

A composite coating and laser cladding technology, which is applied in the field of material surface modification, can solve the problems of low dilution and poor anti-friction performance, and achieve a wide range of content changes, excellent wear resistance and anti-friction performance, and good metallurgical bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in combination with specific embodiments.

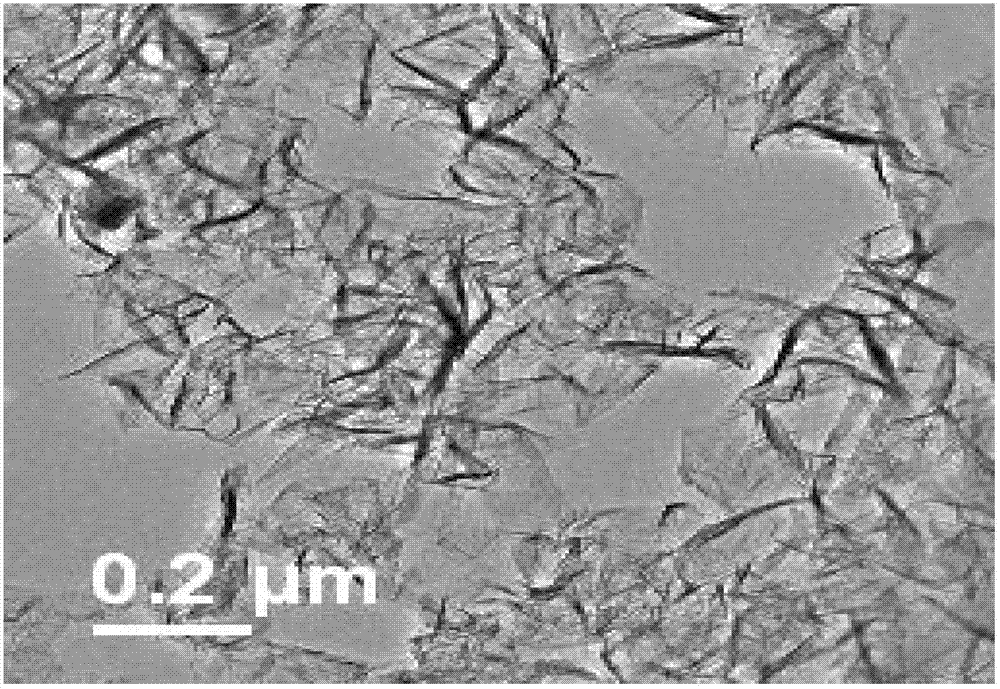

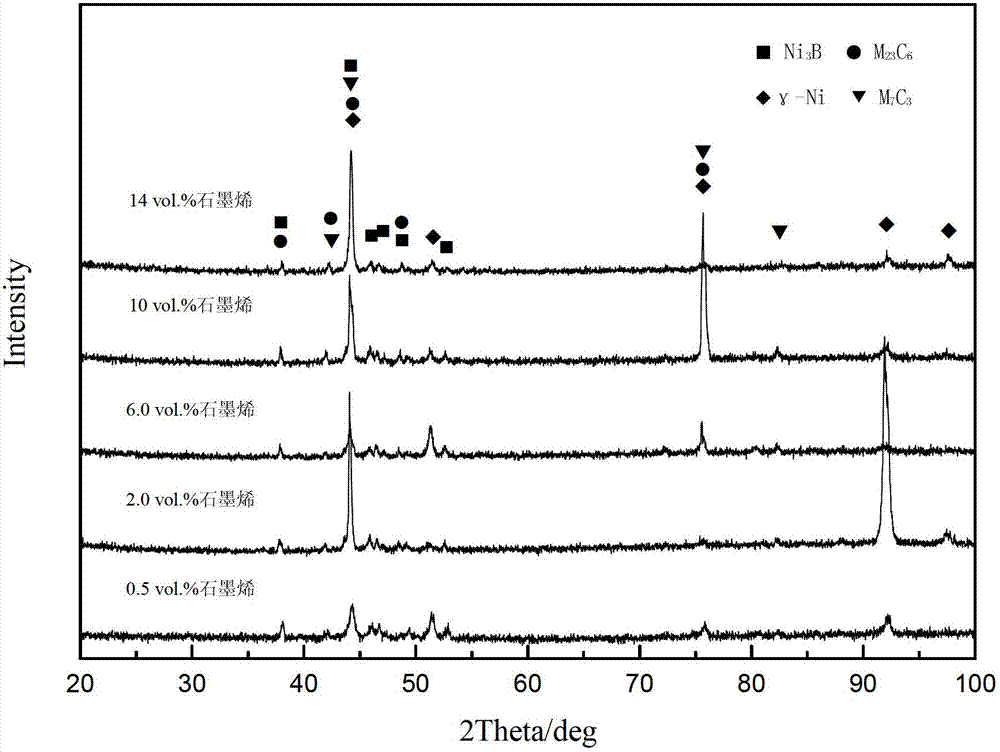

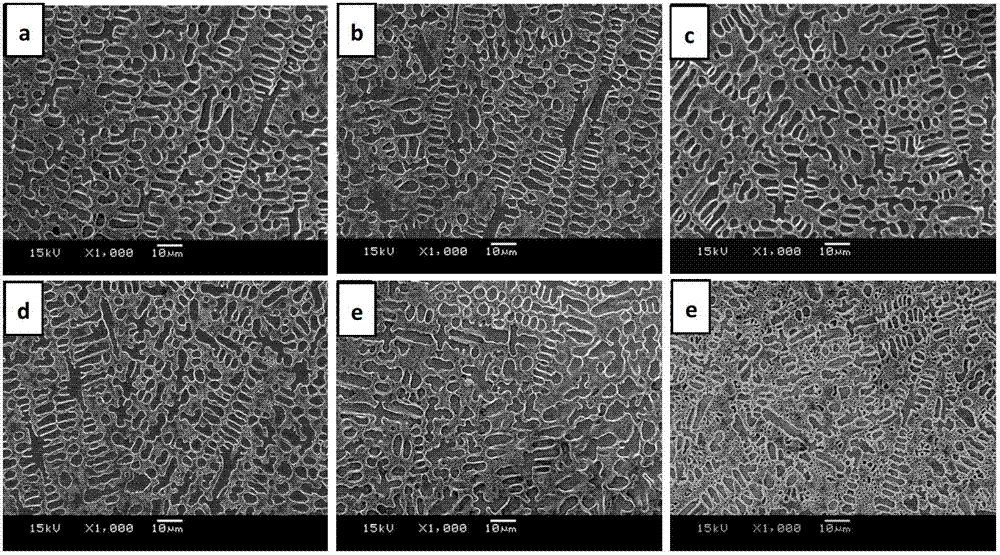

[0029] Select Ni with a particle size of 45-180μm 65.8 Cr 15 B 3.0 Si 3.5 C 0.7 Fe 12 Nickel-based self-fluxing alloy powder is used as the matrix material of the cladding layer, and graphene with a particle size of 20nm is selected as the reinforcing phase, and its addition amount is 0.5-14 vol.%. Firstly, the composite powder is prepared according to the stoichiometric ratio. Then, use a ball mill to uniformly mix the prepared composite powder. The specific parameters during mixing are: ball mill speed 300rpm, mixing time 5h. Pre-place the composite powder on the surface of 300M steel (the thickness of the pre-set layer is 1mm), and use a 5KW cross-flow CO2 laser to perform multi-channel overlapping laser cladding under the protection of argon. The specific process parameters of laser cladding are: laser power 3.0KW, scanning speed 3.0mm / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com