Zirconium-based amorphous alloy

A technology of zirconium-based amorphous alloys and amorphous alloys, applied in the field of metal alloys, can solve the problem of parts and products that cannot be prepared with amorphous structures, Zr-based amorphous alloys have high preparation costs and cannot meet large-scale mass production and other problems, to achieve the effect of inhibiting the crystallization tendency, improving the ability of amorphous formation, and avoiding crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

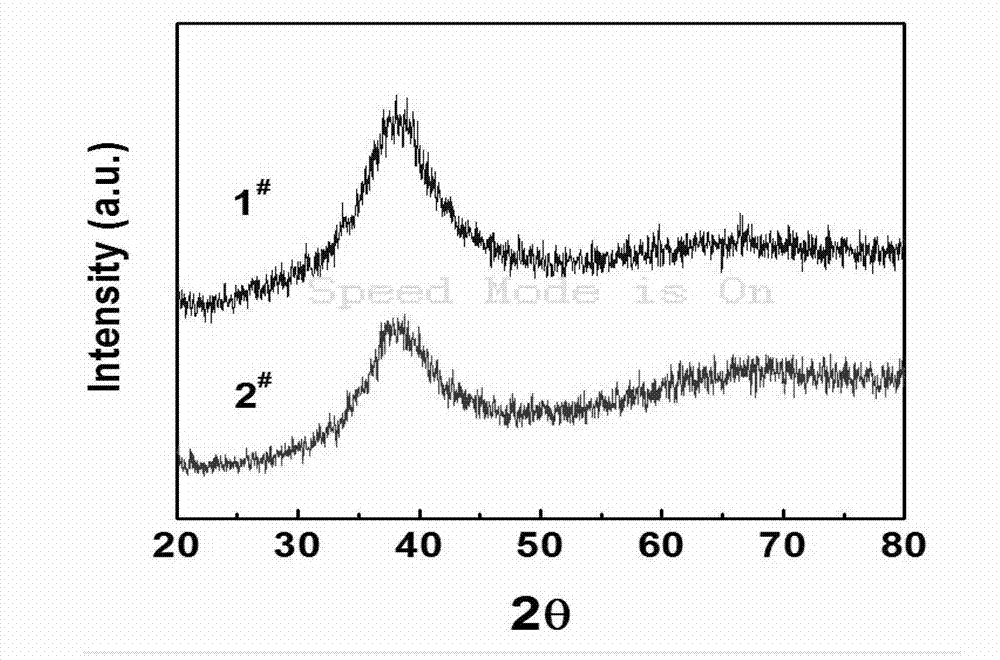

Embodiment 1

[0048] The first embodiment of the present invention provides a zirconium-based amorphous alloy whose composition and atomic percentage conform to the following general formula:

[0049] Zr a Cu b Ni c Al d Re e ,

[0050] Among them, a, b, c, d, e are the atomic percentage content of each element in the amorphous alloy, respectively: 56≤a≤65, 15≤b≤32, 2≤c≤15, 7≤d≤13 , 0.05≤e≤2.

[0051] , Re is one or more elements in the rare earth, that is, Re is the La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, Lu element A combination of one or more or Re is one or more of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, Lu and The combination of Y. The Re element group can be obtained by adding Misch Metal.

[0052] According to the general formula, the above-mentioned zirconium-based amorphous alloy manufacturing method is used for batching, smelting, and casting cooling to form the zirconium-based amorphous alloy expressed by the general formula.

[0053] Among them,...

Embodiment 2

[0055] The second embodiment of the present invention provides a zirconium-based amorphous alloy whose composition and atomic percentage conform to the following general formula:

[0056] Zr a Cu b Ni c Al d Re e ,

[0057] Among them, a, b, c, d, e are the atomic percentage content of each element in the amorphous alloy, respectively: 45≤a≤55, 25≤b≤38, 2≤c≤15, 7≤d≤13 , 0.05≤e≤2, where Re is one or more elements in rare earths, that is, Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm A combination of one or more of, Yb, Lu elements or Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, Lu elements A combination of one or more and Y. The Re element group can be obtained by adding Misch Metal.

[0058] According to the general formula, the above-mentioned zirconium-based amorphous alloy manufacturing method is used for batching, smelting, and casting cooling to form the zirconium-based amorphous alloy expressed by the general formula.

[0059] Wherein in th...

Embodiment 3

[0061] The third embodiment of the present invention provides a zirconium-based amorphous alloy whose composition and atomic percentage conform to the following general formula:

[0062] (Zr,Hf) a Cu b Ni c Al d Re e ,

[0063] Among them, a, b, c, d, e are the atomic percentage content of each element in the amorphous alloy, respectively: 58≤a≤65, 15≤b≤32, 2≤c≤15, 7≤d≤13 , 0.05≤e≤2, Re is one or more elements in the rare earth, that is, Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, A combination of one or more of Yb and Lu elements or Re is one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, Lu elements One or more combinations with Y. The Re element group can be obtained by adding Misch Metal.

[0064] According to the general formula, the above-mentioned zirconium-based amorphous alloy manufacturing method is used for batching, smelting, and casting cooling to form the zirconium-based amorphous alloy expressed by the general formula.

[0065] Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com